Are you gearing up for an interview for a Shellfish Processing Machine Tender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Shellfish Processing Machine Tender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

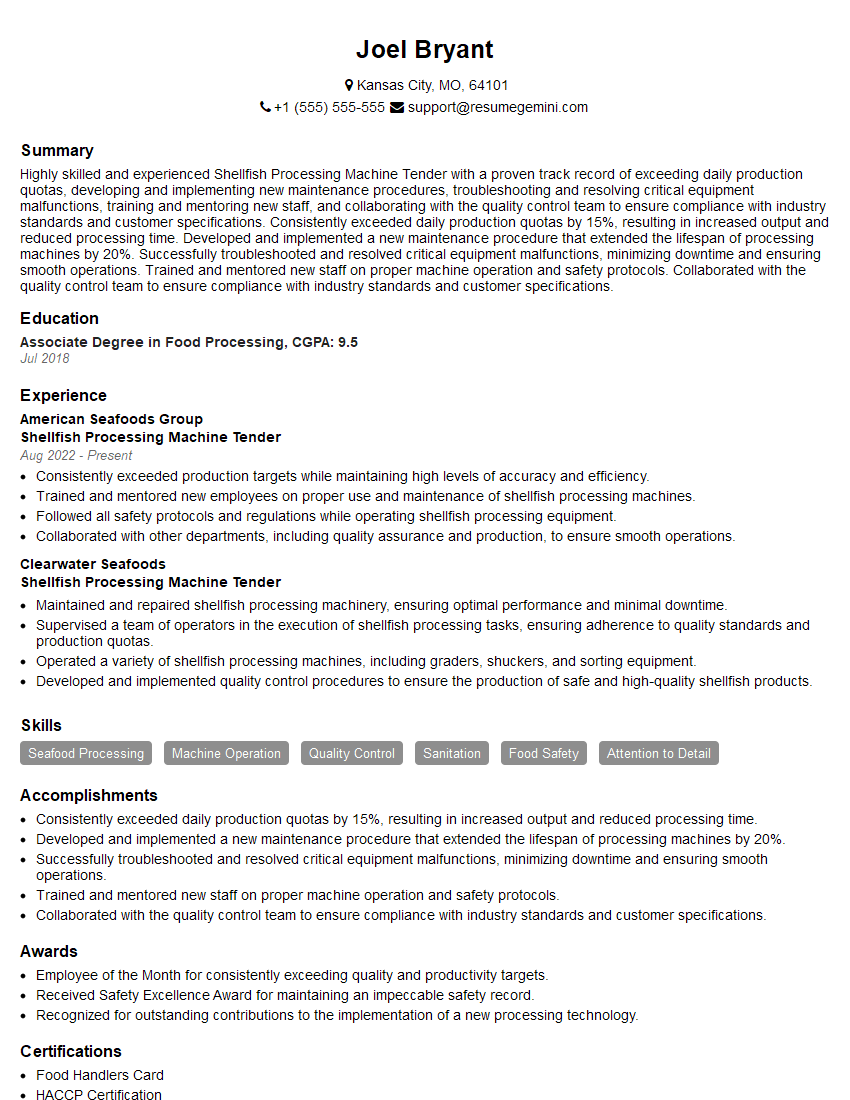

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shellfish Processing Machine Tender

1. What are the key responsibilities of a Shellfish Processing Machine Tender?

As a Shellfish Processing Machine Tender, I will be responsible for a range of tasks, including:

- Monitoring and operating shellfish processing machinery to ensure efficient operation and minimize downtime.

- Cleaning and sanitizing equipment and work areas to maintain a hygienic and safe work environment.

- Inspecting shellfish to ensure they meet quality standards and removing any defective or contaminated products.

- Packaging and labeling shellfish products according to customer specifications.

- Maintaining inventory levels and coordinating with other departments to ensure a smooth flow of production.

2. What are the different types of shellfish processing machines, and how do they work?

Types of Shellfish Processing Machines

- Grading Machines: These machines separate shellfish based on size, shape, and weight.

- Washing Machines: These machines clean and sanitize shellfish using high-pressure water jets.

- Shucking Machines: These machines mechanically remove the shells from shellfish.

- Cooking Machines: These machines cook shellfish using various methods, such as steaming, boiling, or frying.

- Packaging Machines: These machines package shellfish products into containers for distribution.

How Shellfish Processing Machines Work

- Grading machines use a combination of belts, screens, and sensors to sort shellfish.

- Washing machines use high-pressure water jets to remove dirt, debris, and bacteria from shellfish.

- Shucking machines use a variety of mechanical means to remove the shells from shellfish.

- Cooking machines use heat to cook shellfish to a desired doneness.

- Packaging machines use various methods to package shellfish products, such as vacuum sealing, shrink wrapping, and cartoning.

3. What are the safety hazards associated with shellfish processing, and how can they be minimized?

- Sharp objects: Shellfish processing involves the use of sharp knives and other tools, which can cause cuts and lacerations.

- Slippery surfaces: Shellfish processing areas can be wet and slippery, increasing the risk of slips and falls.

- Biological hazards: Shellfish can carry bacteria and viruses that can cause foodborne illnesses.

- Heavy lifting: Shellfish processing often involves lifting heavy containers and equipment.

- Repetitive motions: Shellfish processing can involve repetitive motions that can lead to musculoskeletal disorders.

- To minimize these hazards, it is important to:

- Wear appropriate safety gear, such as gloves, aprons, and non-slip footwear.

- Keep work areas clean and dry.

- Follow proper food handling procedures to prevent contamination.

- Use proper lifting techniques to avoid injury.

- Take breaks and stretch regularly to prevent repetitive motion injuries.

4. What are the quality control procedures for shellfish processing?

Quality control procedures for shellfish processing include:

- Visual inspection of shellfish for defects, contamination, and freshness.

- Microbiological testing to ensure the absence of harmful bacteria and viruses.

- Chemical testing to ensure the absence of harmful chemicals and toxins.

- Temperature monitoring to ensure that shellfish are stored and processed at the correct temperatures.

- Record keeping to document all quality control activities and ensure traceability.

5. What is the importance of sanitation in shellfish processing?

Sanitation is extremely important in shellfish processing to prevent the contamination of shellfish products with harmful bacteria and viruses. Shellfish can carry bacteria such as Salmonella, Vibrio, and E. coli, which can cause foodborne illnesses. To prevent contamination, it is essential to maintain a clean and sanitary work environment, follow proper food handling procedures, and regularly clean and sanitize equipment.

6. What are the different methods used to preserve shellfish?

- Freezing: Freezing is a common method of preserving shellfish. Shellfish can be frozen whole, shucked, or cooked.

- Canning: Canning is another method of preserving shellfish. Shellfish are cooked and sealed in airtight cans to prevent spoilage.

- Drying: Drying is a traditional method of preserving shellfish. Shellfish are dried in the sun or in a dehydrator to remove moisture and prevent spoilage.

- Smoking: Smoking is a method of preserving shellfish by exposing them to smoke. Smoking helps to preserve shellfish and gives them a unique flavor.

7. What are the different types of shellfish that are commercially processed?

- Clams

- Oysters

- Mussels

- Scallops

- Shrimp

- Lobster

- Crab

8. What are the challenges of shellfish processing?

- Shellfish processing can be labor-intensive, especially when it comes to tasks such as shucking and cleaning.

- Shellfish are perishable and must be processed quickly to prevent spoilage.

- Shellfish can carry harmful bacteria and viruses, so it is important to follow strict sanitation procedures to prevent contamination.

- Shellfish processing can be seasonal, which can lead to fluctuations in production and employment.

9. What are the trends in shellfish processing?

- There is a growing demand for shellfish products, both domestically and internationally.

- Consumers are becoming more interested in sustainable seafood, and shellfish farming is a more sustainable option than wild-caught shellfish.

- New technologies are being developed to improve the efficiency and safety of shellfish processing.

- There is a growing interest in value-added shellfish products, such as smoked shellfish and shellfish-based sauces.

10. What are your career goals?

My career goal is to become a Shellfish Processing Supervisor. I am confident that my skills and experience in shellfish processing, as well as my commitment to quality and safety, will make me a valuable asset to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shellfish Processing Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shellfish Processing Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Shellfish Processing Machine Tender primarily operates and maintains specialized machinery used in the processing of shellfish. They play a crucial role in ensuring the efficient and safe production of high-quality shellfish products.

1. Machinery Operation

The machine tender is responsible for:

- Setting up, calibrating, and operating various shellfish processing machines, including shucking, sorting, and grading equipment.

- Monitoring machine performance to ensure optimal efficiency and product quality, and making adjustments as needed.

- Maintaining a clean and organized work area around the machinery, adhering to safety protocols and sanitation standards.

2. Product Quality Assurance

The tender is tasked with:

- Inspecting shellfish products to ensure they meet quality standards, removing any defective or damaged items.

- Collaborating with quality control personnel to maintain and improve product quality.

- Monitoring and recording production data to track yield, efficiency, and quality metrics.

3. Maintenance and Troubleshooting

The machine tender is expected to:

- Perform routine maintenance and upkeep on shellfish processing machines, identifying and resolving minor issues.

- Collaborate with maintenance technicians for major repairs or equipment upgrades.

- Keep a log of maintenance activities and any issues encountered, for future reference and troubleshooting.

4. Safety and Compliance

The tender is responsible for:

- Adhering to all safety regulations and operating procedures in the shellfish processing facility.

- Wearing appropriate personal protective equipment (PPE) and maintaining a safe work environment.

- Following food safety and hygiene guidelines to prevent contamination and ensure product integrity.

Interview Tips

Preparing for an interview for the Shellfish Processing Machine Tender position requires a combination of technical knowledge, attention to detail, and a commitment to safety. Here are some helpful tips to help you ace the interview:

1. Research the Position and Company

Familiarize yourself with the specific job responsibilities and the company’s operations. This will help you understand the role’s expectations and demonstrate your interest in the organization.

2. Practice Your Skills

Review your knowledge of shellfish processing machinery and quality control procedures. Practice operating simulated equipment or using mock products if possible. This will boost your confidence during the interview and highlight your practical abilities.

3. Highlight Your Safety Consciousness

Emphasize your commitment to safety and regulatory compliance in the workplace. Share examples of how you have followed safety protocols and maintained a safe work environment in previous roles.

4. Showcase Your Attention to Detail

Throughout the interview, demonstrate your attention to detail by highlighting your ability to identify and address quality issues, maintain a clean and organized workspace, and keep accurate records.

5. Prepare Questions

At the end of the interview, ask thoughtful questions about the position, the company’s goals, and any opportunities for professional development. This shows your engagement and interest in the role.

Next Step:

Now that you’re armed with the knowledge of Shellfish Processing Machine Tender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Shellfish Processing Machine Tender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini