Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Shingle Packer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

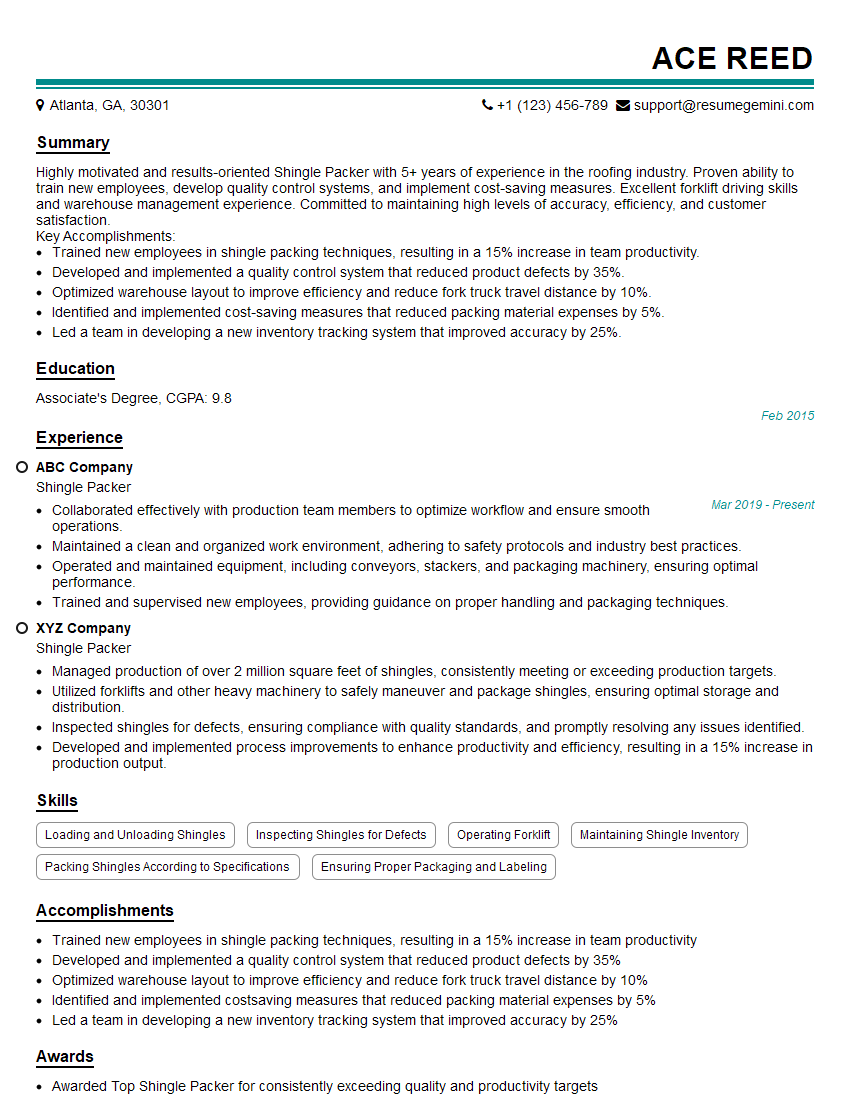

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shingle Packer

1. What is the process of bundling shingles?

The process of bundling shingles involves several key steps:

- Gathering and counting shingles: The shingles are first gathered and counted to ensure the correct number are available for each bundle.

- Aligning and stacking shingles: The shingles are aligned and stacked neatly, ensuring they are facing the same direction and are properly oriented.

- Banding shingles together: A banding machine or hand tool is used to apply banding around the stacked shingles, securing them together into a bundle.

- Labeling and stacking bundles: Each bundle is labeled with information such as the number of shingles, type of shingle, and manufacturer’s name. The bundles are then stacked securely for storage or transportation.

2. How do you ensure the quality of shingles during bundling?

Inspecting shingles before bundling

- Visually inspecting each shingle for any damage, defects, or irregularities.

- Checking for proper size, thickness, and shape.

- Ensuring that the shingles are free from moisture or debris.

Maintaining proper handling techniques

- Handling the shingles carefully to avoid damaging them.

- Using proper tools and equipment for bundling.

- Following established procedures to prevent scratches or breakage.

3. What equipment do you use for bundling shingles?

The equipment commonly used for bundling shingles includes:

- Banding machine: An automated machine designed to apply banding around the shingles, securing them together.

- Hand banding tool: A manual tool used to apply banding when a banding machine is not available.

- Skids or pallets: Flat platforms used to support the bundles during storage or transportation.

- Labeling machine or printer: A device used to print and apply labels to each bundle, providing necessary information.

- Forklift or pallet jack: Equipment used to move and stack bundles efficiently.

4. How do you handle and stack bundles of shingles safely?

- Proper lifting technique: Lifting bundles with proper posture and bending at the knees, not the waist.

- Secure stacking: Stacking bundles on stable surfaces, ensuring they are balanced and not leaning.

- Interlocking bundles: Interlocking the bundles together to create a stable stack, preventing them from toppling over.

- Using straps or bands: Securing the bundles with straps or bands when stacking them high.

- Avoiding overloading: Not overloading the stack to prevent collapse or damage.

5. What safety precautions should be taken when working with shingles?

- Wearing appropriate PPE: Wearing protective gear such as gloves, safety glasses, and a hard hat.

- Using sharp tools carefully: Handling sharp tools, such as knives or utility knives, with caution.

- Maintaining a clean work area: Keeping the work area free of debris and tripping hazards.

- Being aware of surroundings: Paying attention to potential hazards in the work environment, such as overhead wires or uneven surfaces.

- Following established safety protocols: Adhering to safety guidelines and procedures specific to the workplace.

6. What is your experience with different types of roofing materials?

I have experience working with a variety of roofing materials, including:

- Asphalt shingles: The most common type of roofing material, known for its durability, affordability, and versatility.

- Metal roofing: A lightweight and long-lasting option, available in various styles and colors.

- Tile roofing: A durable and fire-resistant material, often used in warmer climates.

- Wood shingles and shakes: Natural materials that provide a rustic and traditional look.

- Slate roofing: A high-end and durable material known for its longevity and natural beauty.

7. What challenges have you faced in your previous role as a shingle packer?

- Maintaining efficiency and accuracy: Balancing the need for speed with ensuring precision in bundling shingles.

- Working in various weather conditions: Adapting to different weather conditions, such as extreme heat, cold, or rain, while maintaining productivity.

- Handling heavy bundles: Safely lifting and stacking heavy bundles of shingles without causing injury.

- Meeting production targets: Consistently meeting or exceeding production goals while maintaining quality standards.

- Collaborating with team members: Effectively communicating and collaborating with colleagues to ensure a smooth workflow.

8. What techniques do you use to improve your productivity as a shingle packer?

- Streamlining workflow: Optimizing the bundling process by eliminating unnecessary steps and improving efficiency.

- Proper equipment maintenance: Regularly maintaining equipment to minimize downtime and ensure smooth operation.

- Staying organized: Keeping the work area organized to reduce wasted time searching for materials.

- Utilizing available resources: Effectively utilizing available tools and resources to enhance productivity.

- Continuous improvement: Seeking opportunities to improve techniques and processes to increase efficiency.

9. How do you prioritize tasks and manage your time effectively?

I prioritize tasks based on the following criteria:

- Urgency: Identifying and addressing tasks that require immediate attention.

- Importance: Determining the significance of tasks in relation to overall goals.

- Dependencies: Considering the tasks that must be completed before others can be started.

- Deadlines: Meeting established deadlines and managing time accordingly.

To manage my time effectively, I use the following techniques:

- Creating a daily schedule: Planning and allocating time for specific tasks throughout the day.

- Setting priorities: Identifying the most important tasks and focusing on completing them first.

- Breaking down large tasks: Dividing complex tasks into smaller, manageable steps to avoid feeling overwhelmed.

- Minimizing distractions: Creating a distraction-free work environment to maintain focus and efficiency.

10. What is your understanding of the company’s quality control standards for shingle bundling?

I understand that the company places a high priority on maintaining the quality of its shingle bundles. The quality control standards that I am familiar with include:

- Shingle count accuracy: Ensuring that each bundle contains the correct number of shingles.

- Proper alignment and stacking: Bundling shingles in a neat and aligned manner, preventing damage or breakage.

- Secure banding: Applying banding tightly and securely to hold the shingles together during transportation and storage.

- Label accuracy: Verifying that each bundle is labeled correctly with information such as shingle type, quantity, and manufacturer.

- Visual inspection: Inspecting bundles for any damage, defects, or irregularities before they are shipped out.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shingle Packer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shingle Packer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Inspect and Prepare Shingles

The primary responsibility of a Shingle Packer is to ensure the quality and integrity of the shingles before packaging. This involves visually inspecting shingles for any defects, such as tears, cracks, or missing materials, and removing any damaged or substandard shingles.

- Examine shingles for any visible defects or imperfections, using specified quality standards.

- Sort damaged or defective shingles and remove them from the production line.

- Prepare shingles by removing excess material or debris, ensuring they are ready for packaging.

2. Pack and Label Shingles

Shingle Packers are responsible for efficiently and accurately packing shingles into bundles or cartons. They must follow established packaging procedures and ensure the correct number and type of shingles are included in each bundle.

- Pack shingles into bundles or cartons, following specified packaging standards and guidelines.

- Count and verify the number of shingles in each bundle, ensuring accuracy and consistency.

- Label bundles or cartons with appropriate product information, including type, grade, and quantity.

3. Maintain Equipment and Work Area

To ensure the smooth and efficient operation of the packaging process, Shingle Packers are responsible for maintaining their equipment and work area. They must regularly clean and inspect equipment, and report any issues to the supervisor.

- Clean and maintain packaging equipment, including conveyors, bundlers, and labelers.

- Inspect equipment for any signs of wear or damage, and report any issues promptly.

- Maintain a clean and organized work area, ensuring safety and efficiency.

4. Adhere to Safety Regulations

Shingle Packers are responsible for adhering to all safety regulations and guidelines established by the company and regulatory authorities. They must wear appropriate personal protective equipment and follow safe work practices to prevent injuries.

- Wear appropriate personal protective equipment, such as gloves, safety glasses, and hearing protection.

- Follow established safety procedures and guidelines, including proper lifting techniques and machine operation.

- Report any safety hazards or concerns to the supervisor immediately.

Interview Tips

1. Research the Company and Position

Before the interview, take the time to research the company and the specific Shingle Packer position. This will give you a better understanding of the company’s culture, values, and the specific responsibilities of the role. You can find this information on the company’s website, social media pages, and industry publications.

- Visit the company’s website to learn about their mission, values, and products or services.

- Read industry news and articles to stay informed about the latest trends and best practices.

- Check the company’s social media pages to get a sense of their culture and employee engagement.

2. Prepare Your Answers to Common Interview Questions

There are a number of common interview questions that you can expect to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to prepare your answers to these questions in advance so that you can deliver them confidently and clearly.

- Practice answering common interview questions in front of a mirror or with a friend or family member.

- Tailor your answers to the specific position and company you are interviewing with.

- Highlight your relevant skills and experience, and how they align with the job requirements.

3. Ask Questions During the Interview

Asking questions during the interview shows that you are engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role. Some good questions to ask include:

- “What are the biggest challenges facing the company right now?”

- “What is the company’s culture like?”

- “What are the opportunities for advancement within the company?”

4. Follow Up After the Interview

After the interview, it is important to follow up with the interviewer. This shows that you are still interested in the position and that you appreciate their time. You can follow up by sending a thank-you note or email, or by calling the interviewer to reiterate your interest.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Shingle Packer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!