Are you gearing up for an interview for a Ship Fastener position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Ship Fastener and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

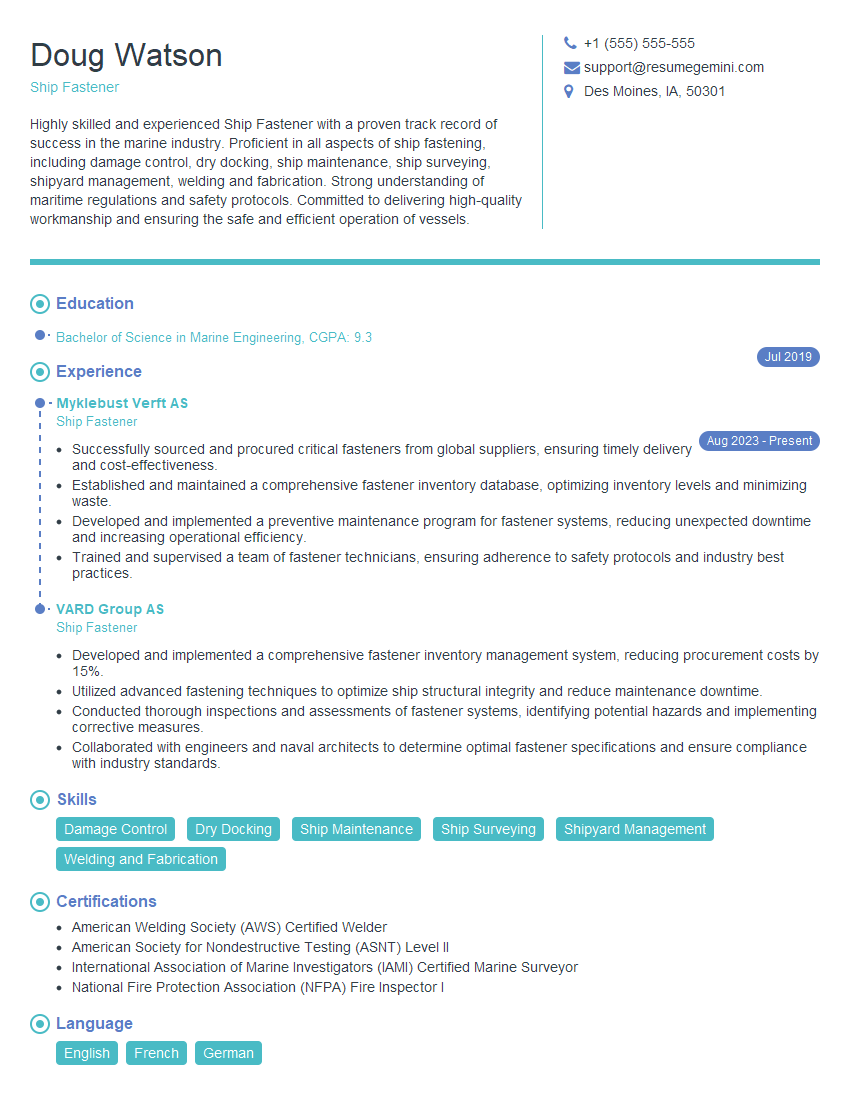

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ship Fastener

1. How do you determine the appropriate size and type of fastener for a given application in shipbuilding?

To determine the appropriate size and type of fastener for a given application in shipbuilding, I consider several factors:

- Material thickness: The thickness of the materials being fastened determines the length of the fastener required.

- Load: The load that the fastener will be subjected to determines its diameter and strength.

- Environment: The environment in which the fastener will be used (e.g., saltwater, high temperatures) influences the material and corrosion resistance required.

- Codes and standards: I adhere to industry codes and standards, such as the American Bureau of Shipping (ABS) and International Association of Classification Societies (IACS), to ensure compliance with safety and performance requirements.

2. What types of non-destructive testing (NDT) methods are commonly used to inspect ship fasteners?

Visual Inspection

- Inspecting fasteners for cracks, corrosion, or any other visible defects.

- Using a magnifying glass or borescope for closer examination.

Magnetic Particle Inspection

- Applying a magnetic field to the fastener.

- Sprinkling magnetic particles on the surface.

- Detecting surface cracks or defects where particles gather.

Ultrasonic Testing

- Sending high-frequency sound waves through the fastener.

- Detecting internal flaws or defects by analyzing the reflected sound waves.

3. How do you ensure the proper torque is applied to ship fasteners?

To ensure proper torque is applied to ship fasteners, I follow these steps:

- Use calibrated torque tools: Calibrated torque wrenches or screwdrivers ensure accurate and consistent torque application.

- Follow manufacturer’s specifications: Refer to fastener specifications to determine the recommended torque values.

- Lubricate threads: Proper lubrication reduces friction and allows for more precise torque application.

- Inspect final torque: Upon tightening, I re-check the torque to ensure it meets the specified value.

4. What procedures do you follow for the storage and handling of ship fasteners?

To ensure the proper storage and handling of ship fasteners, I adhere to the following procedures:

- Proper storage conditions: Store fasteners in a dry, controlled environment to prevent corrosion and damage.

- Organized inventory: Implement a well-organized inventory system to facilitate fastener traceability and prevent mix-ups.

- Handling with care: Avoid dropping or mishandling fasteners that could damage their threads or surfaces.

- Protective packaging: Use appropriate packaging materials, such as anti-corrosion wraps or desiccants, to protect fasteners during storage and transportation.

5. How do you keep up to date with the latest developments in ship fastener technology?

To stay abreast of the latest developments in ship fastener technology, I employ several strategies:

- Attend industry conferences and exhibitions: These events provide valuable opportunities to learn about new products, technologies, and best practices.

- Read technical publications and journals: I subscribe to industry publications and journals to stay informed about research and innovations in the field.

- Engage with industry experts: Attend webinars or participate in online forums to connect with ship fastener experts and exchange knowledge.

- Participate in continuing education programs: I attend workshops or training courses to enhance my technical skills and stay up-to-date with industry advancements.

6. How do you troubleshoot common problems encountered with ship fasteners?

To troubleshoot common problems encountered with ship fasteners, I follow a systematic approach:

- Identify the problem: Determine the specific issue affecting the fastener, such as loose connections, corrosion, or damaged threads.

- Inspect the fastener: Visually inspect the fastener for any visible defects or damage. Use appropriate NDT methods if necessary.

- Consider the application: Evaluate the application where the fastener is used. Factors like load, environmental conditions, and material compatibility can influence fastener performance.

- Determine the cause: Analyze the inspection results and application factors to identify the root cause of the problem.

- Develop a solution: Implement appropriate corrective actions, such as replacing the fastener, applying anti-corrosion measures, or modifying the installation procedure.

7. How do you ensure the traceability of ship fasteners throughout their lifecycle?

To ensure traceability of ship fasteners throughout their lifecycle, I implement the following practices:

- Establish a unique identification system: Assign unique identification numbers or codes to each fastener.

- Maintain documentation: Record fastener information, including size, material, supplier, and date of installation, in a central database or logbook.

- Use barcodes or RFID tags: Attach barcodes or RFID tags to fasteners for quick and accurate identification.

- Implement quality control measures: Regularly inspect and verify fastener traceability records to ensure accuracy and completeness.

8. How do you collaborate with other disciplines involved in shipbuilding, such as engineers, designers, and quality control personnel?

To effectively collaborate with other disciplines involved in shipbuilding, I employ the following strategies:

- Regular communication: Attend project meetings, participate in design reviews, and engage in ongoing discussions to share information and coordinate efforts.

- Understanding of project requirements: Familiarize myself with the overall project specifications and design intent to ensure fasteners meet the required performance and safety standards.

- Seeking feedback: Regularly consult with engineers, designers, and quality control personnel to obtain their input and feedback on fastener selection and installation practices.

- Adopting a team-oriented approach: Work as part of a cohesive team, contributing my expertise and actively participating in problem-solving and decision-making processes.

9. How do you manage the supply chain for ship fasteners, including vendor selection, inventory control, and quality assurance?

To effectively manage the supply chain for ship fasteners, I implement the following measures:

- Vendor selection: Conduct thorough vendor assessments to evaluate their capabilities, quality standards, and reliability. Establish long-term partnerships with reputable suppliers.

- Inventory control: Implement an inventory management system to optimize stock levels, minimize waste, and ensure timely availability of fasteners.

- Quality assurance: Establish clear quality standards and inspection procedures to ensure that fasteners meet the required specifications. Conduct regular supplier audits to verify compliance.

- Risk management: Identify and mitigate potential supply chain risks, such as material shortages, production delays, or transportation disruptions, to ensure uninterrupted fastener supply.

10. How do you stay informed about regulatory changes and industry best practices related to ship fasteners?

To stay abreast of regulatory changes and industry best practices related to ship fasteners, I employ the following strategies:

- Monitor regulatory agencies: Regularly review updates and amendments to relevant industry regulations and standards, such as those issued by the American Bureau of Shipping (ABS) or International Association of Classification Societies (IACS).

- Attend industry events and webinars: Participate in conferences, workshops, and online seminars to gain insights into the latest developments and best practices in ship fastener technology and applications.

- Engage with professional organizations: Join industry associations, such as the Society of Naval Architects and Marine Engineers (SNAME), to connect with other professionals and access valuable resources and publications.

- Subscribe to industry journals and newsletters: Regularly read technical publications and newsletters to stay informed about advancements in the field of ship fasteners.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ship Fastener.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ship Fastener‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ship Fasteners are responsible for installing, maintaining, and repairing fasteners on ships. They work under the supervision of a Marine Engineer or a Shipwright.

1. Installation

Ship Fasteners install fasteners such as bolts, nuts, rivets, and screws on ships.

- Measure and mark the location of the fasteners.

- Drill holes for the fasteners.

- Insert the fasteners into the holes and tighten them.

2. Maintenance

Ship Fasteners maintain fasteners by inspecting them for damage and corrosion. They also lubricate and adjust fasteners as needed.

- Inspect fasteners for damage and corrosion.

- Lubricate and adjust fasteners as needed.

- Replace damaged or corroded fasteners.

3. Repair

Ship Fasteners repair fasteners by welding, grinding, or replacing them. They also repair the surrounding metal if it has been damaged.

- Weld, grind, or replace damaged fasteners.

- Repair the surrounding metal if it has been damaged.

4. Safety

Ship Fasteners must follow all safety regulations when working on ships. They must wear appropriate safety gear and use proper tools and equipment.

- Follow all safety regulations when working on ships.

- Wear appropriate safety gear.

- Use proper tools and equipment.

Interview Tips

Preparing for an interview for a Ship Fastener position can be daunting, but with the right preparation, you can increase your chances of success.

1. Research the Company

Before your interview, take some time to research the company you are applying to. This will help you understand their business, their culture, and their specific needs.

- Visit the company’s website.

- Read their annual report.

- Talk to people who work for the company.

2. Practice Your Answers

Once you have a good understanding of the company, you should start practicing your answers to common interview questions. This will help you feel more confident and prepared during your interview.

- Think about your skills and experience.

- Prepare answers to common interview questions.

- Practice your answers out loud.

3. Be Yourself

During your interview, it is important to be yourself. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

- Be honest about your skills and experience.

- Be enthusiastic and positive.

- Be yourself!

4. Follow Up

After your interview, be sure to follow up with the interviewer. This will show them that you are interested in the position and that you are serious about working for the company.

- Send a thank-you note.

- Follow up with the interviewer a week or two after your interview.

Next Step:

Now that you’re armed with the knowledge of Ship Fastener interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Ship Fastener positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini