Feeling lost in a sea of interview questions? Landed that dream interview for Ship Joiner but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Ship Joiner interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

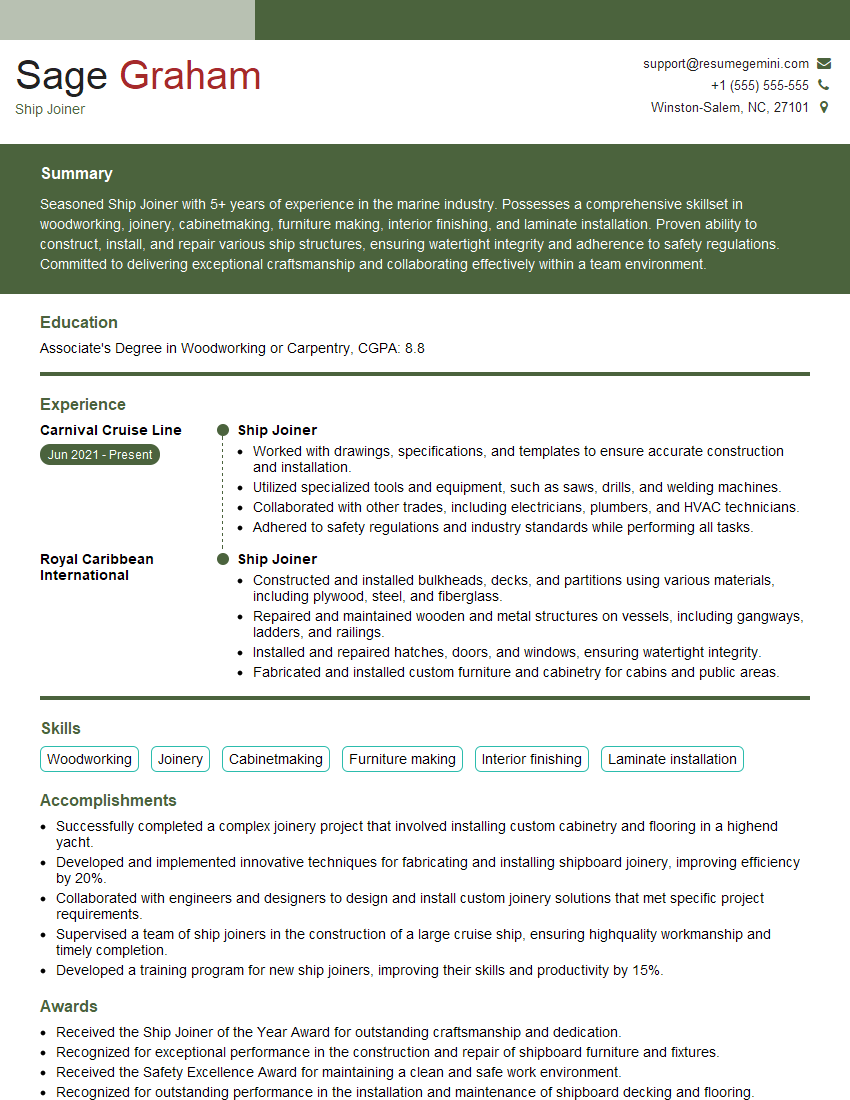

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ship Joiner

1. What are the different types of joints used in shipbuilding?

Different types of joints used in shipbuilding include:

- Butt joint: Two pieces of material are placed edge-to-edge and joined together.

- Edge joint: Two pieces of material are placed side-by-side and joined together.

- Lap joint: One piece of material is overlapped by another piece and joined together.

- T-joint: A T-shaped joint is created by joining two pieces of material together at right angles.

- Corner joint: A corner joint is created by joining two pieces of material together at an angle.

2. What are the different types of materials used in shipbuilding?

Metals

- Steel: Steel is the most common material used in shipbuilding, due to its strength and durability.

- Aluminum: Aluminum is used in shipbuilding for its light weight and corrosion resistance.

- Titanium: Titanium is used in shipbuilding for its high strength and corrosion resistance.

Non-metals

- Fiberglass: Fiberglass is used in shipbuilding for its light weight and durability.

- Wood: Wood is used in shipbuilding for its buoyancy and insulation properties.

- Carbon fiber: Carbon fiber is used in shipbuilding for its high strength and light weight.

3. What are the different types of tools used in shipbuilding?

Different types of tools used in shipbuilding include:

- Power tools: Power tools, such as drills, saws, and sanders, are used to cut, shape, and join materials.

- Hand tools: Hand tools, such as hammers, wrenches, and screwdrivers, are used to assemble and disassemble components.

- Measuring tools: Measuring tools, such as rulers, tape measures, and levels, are used to ensure that components are accurately sized and positioned.

- Safety equipment: Safety equipment, such as hard hats, safety glasses, and gloves, is used to protect workers from hazards.

4. What are the different types of welding processes used in shipbuilding?

Different types of welding processes used in shipbuilding include:

- Arc welding: Arc welding is a type of welding that uses an electric arc to melt the metal and join it together.

- MIG welding: MIG welding, also known as metal inert gas welding, is a type of arc welding that uses a consumable electrode and a shielding gas.

- TIG welding: TIG welding, also known as tungsten inert gas welding, is a type of arc welding that uses a non-consumable tungsten electrode and a shielding gas.

5. What are the different types of painting systems used in shipbuilding?

Different types of painting systems used in shipbuilding include:

- Antifouling paint: Antifouling paint is a type of paint that is applied to the underwater hull of a ship to prevent the growth of marine organisms.

- Topside paint: Topside paint is a type of paint that is applied to the above-water hull of a ship to protect it from the elements.

- Interior paint: Interior paint is a type of paint that is applied to the interior of a ship to protect it from moisture and damage.

6. What are the different types of safety hazards associated with shipbuilding?

Different types of safety hazards associated with shipbuilding include:

- Falls: Falls are a major hazard in shipbuilding, as workers often work at heights.

- Electrical hazards: Electrical hazards are a major hazard in shipbuilding, as workers often work with electrical equipment.

- Fire hazards: Fire hazards are a major hazard in shipbuilding, as ships are often made of flammable materials.

- Chemical hazards: Chemical hazards are a major hazard in shipbuilding, as workers often work with chemicals.

- Noise hazards: Noise hazards are a major hazard in shipbuilding, as workers often work in noisy environments.

7. What are the different types of quality control procedures used in shipbuilding?

Different types of quality control procedures used in shipbuilding include:

- Visual inspection: Visual inspection is a type of quality control procedure that involves inspecting a ship for defects.

- Non-destructive testing: Non-destructive testing is a type of quality control procedure that involves using non-destructive methods to test a ship for defects.

- Destructive testing: Destructive testing is a type of quality control procedure that involves destroying a ship or a component of a ship to test it for defects.

8. What are the different types of shipbuilding standards?

Different types of shipbuilding standards include:

- International Maritime Organization (IMO) standards: IMO standards are international standards that are developed by the IMO.

- American Bureau of Shipping (ABS) standards: ABS standards are American standards that are developed by the ABS.

- Lloyd’s Register (LR) standards: LR standards are British standards that are developed by the LR.

9. What are the different types of shipbuilding software?

Different types of shipbuilding software include:

- Computer-aided design (CAD) software: CAD software is used to create 3D models of ships.

- Computer-aided manufacturing (CAM) software: CAM software is used to generate instructions for CNC machines that cut and shape materials.

- Product lifecycle management (PLM) software: PLM software is used to manage the lifecycle of a ship, from design to disposal.

10. What are the different types of shipbuilding jobs?

Different types of shipbuilding jobs include:

- Shipbuilding engineers: Shipbuilding engineers design and build ships.

- Shipbuilding technicians: Shipbuilding technicians assist shipbuilding engineers in the design and construction of ships.

- Shipbuilding welders: Shipbuilding welders weld the different parts of a ship together.

- Shipbuilding painters: Shipbuilding painters paint the different parts of a ship.

- Shipbuilding electricians: Shipbuilding electricians install and maintain the electrical systems of a ship.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ship Joiner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ship Joiner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ship Joiners are responsible for designing, building, and repairing furniture and fixtures on ships.

1. Design

Ship Joiners work with architects and designers to develop plans for furniture and fixtures.

- Measure and inspect spaces to determine requirements.

- Create sketches and drawings of proposed designs.

2. Build

Ship Joiners cut, shape, and assemble materials to build furniture and fixtures.

- Select and prepare materials, including wood, metal, and plastic.

- Use hand and power tools to cut, shape, and join materials.

3. Repair

Ship Joiners repair damaged furniture and fixtures.

- Inspect damaged furniture and fixtures to determine the extent of damage.

- Repair or replace damaged parts.

4. Maintenance

Ship Joiners maintain furniture and fixtures to ensure they are in good condition.

- Clean and inspect furniture and fixtures regularly.

- Perform minor repairs and adjustments.

Interview Tips

Preparing for an interview can be nerve-wracking, but there are several things you can do to increase your chances of success. Here are a few tips:

1. Research the company and the position

Before you go to an interview, it’s important to do your research. This will help you understand the company’s culture, values, and what they’re looking for in a candidate. You should also learn as much as you can about the specific position you’re applying for.

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” or “Why are you interested in this position?” It’s a good idea to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Highlight your skills and experience

When you’re answering interview questions, be sure to highlight your skills and experience that are relevant to the position you’re applying for. Use specific examples to illustrate your qualifications, and be sure to quantify your accomplishments whenever possible.

4. Be prepared to ask questions

Asking questions at the end of an interview shows that you’re interested in the position and that you’re taking the initiative to learn more about the company. It also gives you an opportunity to clarify any information that you didn’t understand during the interview.

Next Step:

Now that you’re armed with the knowledge of Ship Joiner interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Ship Joiner positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini