Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Shirring Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

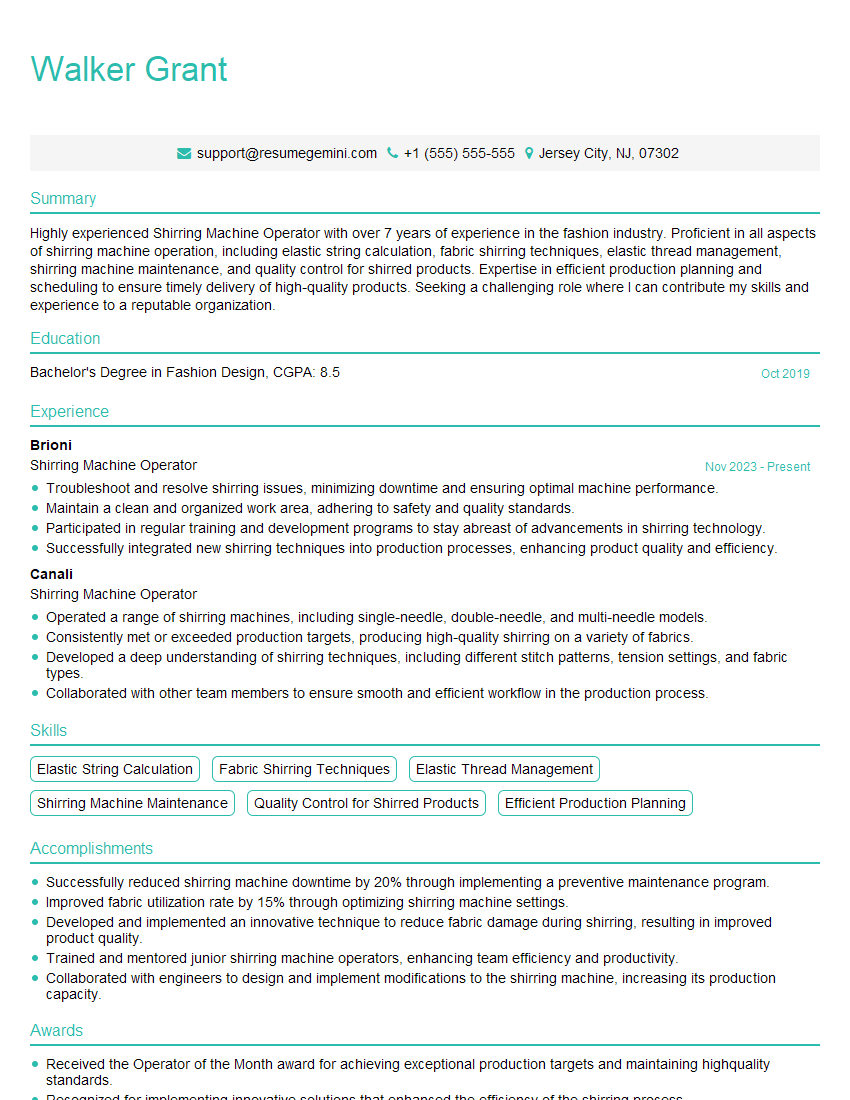

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shirring Machine Operator

1. Describe the detailed process of shirring a fabric?

- Thread the shirring machine with the desired thread.

- Set the machine to the desired stitch length and tension.

- Place the fabric under the presser foot and lower the needle.

- Start sewing, slowly guiding the fabric through the machine.

- Once the fabric is shirred, remove it from the machine and press it.

2. How do you ensure that the shirring is even and consistent?

Checking the Tension

- Check the tension of the thread regularly to ensure that it is even.

- If the tension is too tight, the shirring will be puckered.

- If the tension is too loose, the shirring will be loose and uneven.

Guiding the Fabric

- Guide the fabric through the machine slowly and evenly.

- If the fabric is pulled too quickly, the shirring will be uneven.

- If the fabric is pulled too slowly, the shirring will be too tight.

3. What types of fabrics are best suited for shirring?

- Lightweight fabrics, such as silk, chiffon, and voile.

- Medium-weight fabrics, such as cotton, linen, and rayon.

- Avoid using heavy fabrics, such as denim or canvas, as they will be difficult to shirr.

4. How do you troubleshoot a shirring machine that is not working properly?

- Check the tension of the thread.

- Check the needle to make sure it is sharp and not bent.

- Check the bobbin to make sure it is properly wound.

- Check the machine for any loose or broken parts.

- If you cannot find the problem, consult the machine’s manual.

5. What are some of the different techniques for shirring fabric?

- Basic shirring: This is the most common type of shirring, and it creates a uniform, gathered effect.

- Smocking: This is a more advanced technique that creates a more decorative effect.

- Honeycomb shirring: This technique creates a honeycomb-like effect.

- Circular shirring: This technique creates a circular pattern.

6. What are some of the applications for shirring?

- Gathers on clothing, such as dresses, skirts, and blouses.

- Ruffles on curtains, bedspreads, and pillows.

- Decorative accents on handbags, hats, and other accessories.

7. What safety precautions should be taken when operating a shirring machine?

- Always wear safety glasses.

- Keep hands away from the needle.

- Do not operate the machine if it is damaged or not working properly.

- Unplug the machine before cleaning or making any repairs.

8. How do you maintain a shirring machine?

- Clean the machine regularly with a soft cloth.

- Oil the machine regularly according to the manufacturer’s instructions.

- Check the tension of the thread regularly.

- Have the machine serviced by a qualified technician on a regular basis.

9. What are the different types of shirring attachments?

- Gathering foot: This foot is used to create basic shirring.

- Smocking foot: This foot is used to create smocking.

- Honeycomb foot: This foot is used to create honeycomb shirring.

- Circular shirring foot: This foot is used to create circular shirring.

10. How do you adjust the shirring tension?

- The shirring tension can be adjusted by changing the tension of the thread.

- To increase the tension, turn the tension dial clockwise.

- To decrease the tension, turn the tension dial counterclockwise.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shirring Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shirring Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Shirring Machine Operator is responsible for operating a shirring machine which creates shirring, or gathering, in fabric. Shirring is a technique used to create a gathered or puckered effect on fabric. The shirring machine uses needles to create loops in the fabric, which are then gathered or shirred together to create the desired effect.

1. Machine Operation

The operator is responsible for setting up and operating the shirring machine according to the job specifications. This includes loading the fabric onto the machine, adjusting the machine settings, and monitoring the machine’s operation to ensure that the fabric is shirred correctly.

- Load fabric onto the machine and adjust machine settings to ensure proper shirring.

- Monitor machine operation, make adjustments, and troubleshoot any machine issues.

2. Quality Control

The operator is responsible for inspecting the shirred fabric to ensure that it meets the required quality standards. This includes inspecting for defects, such as missed stitches or uneven shirring.

- Inspect shirred fabric for defects and ensure it meets quality standards.

- Maintain machine and work area to ensure consistent fabric quality.

3. Production

The operator is responsible for meeting production targets by shirring fabric efficiently and accurately. This includes maintaining a consistent speed and quality of work.

- Maintain a consistent speed and quality of work to meet production targets.

- Follow production schedules and work orders to ensure timely completion of orders.

4. Maintenance

The operator is responsible for maintaining the shirring machine in good working condition. This includes cleaning and lubricating the machine, and making minor repairs.

- Clean and lubricate the shirring machine regularly to maintain its functionality.

- Perform minor repairs and maintenance tasks to ensure machine uptime.

Interview Tips

To ace the interview for a Shirring Machine Operator position, it is important to demonstrate your knowledge of the role and your ability to perform the required tasks. Here are some interview tips and hacks that can help you succeed:

1. Research the Company and the Position

Before the interview, take the time to research the company and the specific Shirring Machine Operator position you are applying for. This will help you understand the company’s culture, values, and the specific requirements of the role. You can find information on the company’s website, social media pages, and job description.

- Visit the company website to learn about their products, services, and company culture.

- Read the job description carefully to understand the specific requirements of the role.

2. Highlight Your Experience and Skills

During the interview, be sure to highlight your experience and skills that are relevant to the Shirring Machine Operator role. This includes your experience operating shirring machines, your knowledge of fabric types and qualities, and your ability to maintain and troubleshoot machinery.

- Quantify your accomplishments and provide specific examples of your experience.

- Emphasize your ability to work independently and as part of a team.

3. Prepare Questions for the Interviewer

Preparing questions for the interviewer shows that you are engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role. Some good questions to ask include:

- What are the most important qualities you are looking for in a Shirring Machine Operator?

- What are the biggest challenges facing the company in the coming year?

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you are serious about the position.

- Dress in business casual attire.

- Arrive on time for your interview.

5. Be Confident and Enthusiastic

Finally, be confident and enthusiastic during your interview. This will show the interviewer that you are excited about the opportunity and that you believe in your ability to perform the job.

- Make eye contact with the interviewer.

- Speak clearly and confidently.

Next Step:

Now that you’re armed with the knowledge of Shirring Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Shirring Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini