Feeling lost in a sea of interview questions? Landed that dream interview for Shoe Parts Molder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Shoe Parts Molder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

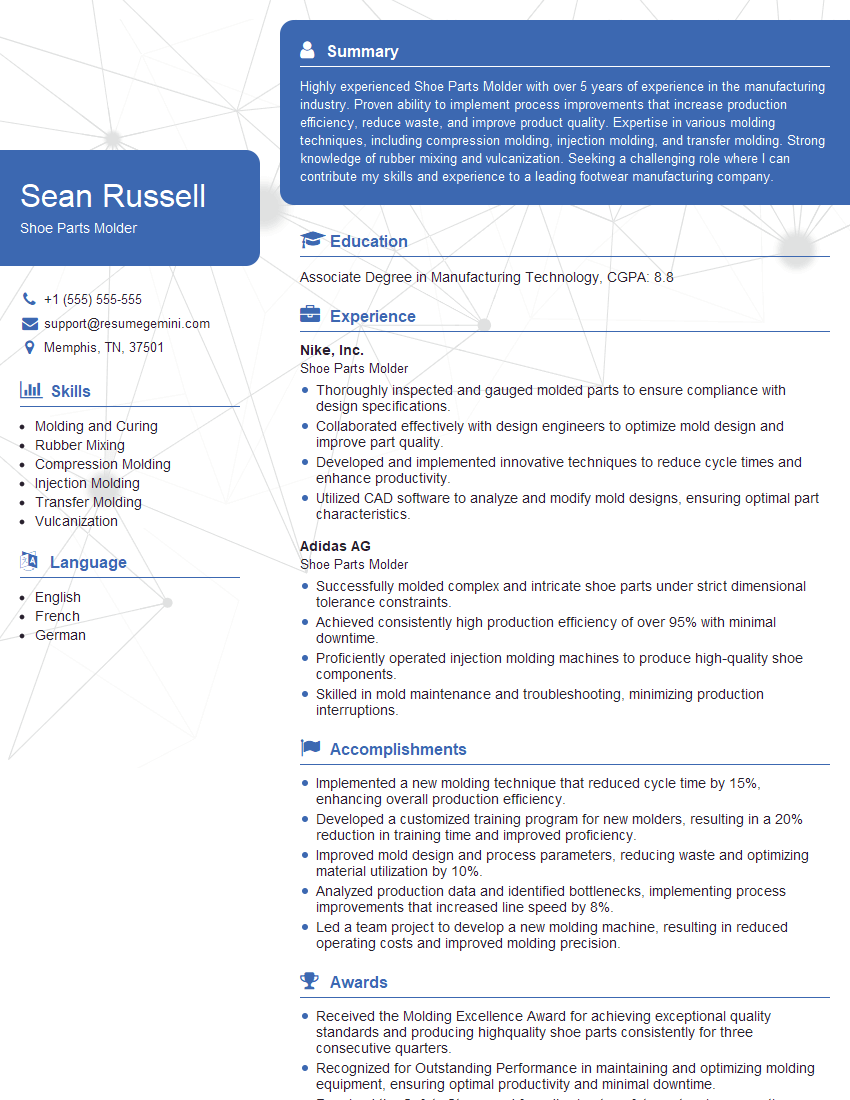

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shoe Parts Molder

1. Explain the different types of molds used in shoe parts molding?

- Compression molding: This is a process where a heated mold is pressed against a rubber or plastic material to form the desired shape. It is commonly used for molding soles and heels.

- Injection molding: In this process, molten plastic or rubber is injected into a mold under pressure. It is suitable for producing complex and intricate parts, such as midsoles and uppers.

- Transfer molding: This method involves transferring molten material from a heating chamber into a mold. It provides better control over material flow and allows for the production of parts with precise dimensions.

- Blow molding: This process uses a heated mold to blow air into a plastic preform, forming it into a hollow part. It is often used for molding air cushioning units.

2. What are the key factors to consider when selecting the appropriate mold material?

Factors to consider when selecting mold material:

- Temperature resistance: The material should be able to withstand the high temperatures involved in molding processes.

- Durability: The material should be strong enough to withstand repeated use and maintain its shape over time.

- Corrosion resistance: The material should be resistant to corrosion and chemicals used in molding.

- Surface finish: The material should provide a smooth and consistent surface finish to the molded parts.

- Cost: The cost of the mold material is also a factor to consider.

Commonly used mold materials:

- Steel: Steel molds are durable, have high temperature resistance, and provide a good surface finish. However, they are more expensive than other materials.

- Aluminum: Aluminum molds are lightweight, durable, and have good heat transfer properties. They are often used for prototype and low-volume production.

- Beryllium copper: Beryllium copper molds are highly durable, have excellent thermal conductivity, and provide a superior surface finish. They are used for high-volume production.

3. Describe the process of mold design and development?

- Design phase: Involves creating a 3D model of the mold using CAD software. The design considers factors such as part geometry, mold materials, and production requirements.

- Mold manufacturing: The mold is manufactured based on the design using CNC machining or other fabrication techniques.

- Mold testing: The mold is tested with sample materials to ensure it produces parts with the desired dimensions, surface finish, and quality.

- Mold optimization: Based on testing results, the mold design may be adjusted to improve efficiency, reduce cycle time, or enhance part quality.

4. Explain the importance of mold maintenance and how it affects product quality?

- Regular mold maintenance helps prevent costly downtime and ensures the production of high-quality parts.

- Proper cleaning and inspection of molds helps detect and resolve issues such as wear, corrosion, or damage.

- Regular lubrication ensures smooth operation of mold components and extends their lifespan.

- Implementing preventative maintenance schedules can help identify potential problems before they escalate, minimizing disruptions and maintaining consistent product quality.

5. Describe the different types of defects that can occur in molded shoe parts and their causes?

- Flash: Excess material that forms around the edges of the part, caused by improper mold closure or worn mold components.

- Sink marks: Depressions or voids on the surface of the part, caused by uneven material shrinkage or insufficient injection pressure.

- Voids: Air pockets or empty spaces within the part, caused by trapped air or insufficient material flow.

- Weld lines: Visible lines on the surface of the part where two streams of material meet, indicating weak bonding between them.

- Surface defects: Scratches, dents, or other imperfections on the surface of the part, caused by mold damage or improper handling.

6. Explain the quality control procedures involved in shoe parts molding?

- Dimensional inspection: Measuring and verifying the dimensions of the molded parts to ensure they meet specifications.

- Surface inspection: Examining the surface of the parts for defects such as scratches, dents, or voids.

- Functional testing: Testing the parts to ensure they meet performance requirements, such as durability, flexibility, and wear resistance.

- Material testing: Analyzing the material properties of the molded parts to verify they meet the specified standards.

- Statistical process control (SPC): Using statistical methods to monitor and control the molding process, ensuring consistent quality.

7. Describe the role of automation in shoe parts molding?

- Automation in shoe parts molding involves using machines or robots to perform tasks such as material handling, mold loading and unloading, and quality inspection.

- Automated systems improve efficiency, reduce labor costs, and increase production capacity.

- Automated mold loading and unloading reduce cycle times and minimize the risk of human error.

- Automated quality inspection systems can detect defects more accurately and consistently than manual inspection.

8. Explain the environmental considerations and sustainability practices in shoe parts molding?

- Shoe parts molding involves the consumption of energy, water, and raw materials.

- Sustainable practices include using energy-efficient equipment, recycling waste materials, and implementing water conservation measures.

- Reducing waste and using recycled materials can contribute to environmental protection.

- Adhering to environmental regulations and industry standards helps minimize the impact on the environment.

9. Describe the latest advancements and trends in shoe parts molding technology?

- Additive manufacturing (3D printing): Used to create complex mold designs and prototypes.

- Multi-component molding: Combining different materials or colors in a single molding process.

- Advanced mold simulation software: Used to optimize mold design and predict potential defects.

- Artificial intelligence (AI): Used for quality control, predictive maintenance, and process optimization.

10. Have you worked with any specific shoe brands or manufacturers? If so, could you share some of your experiences?

- Mention the brands or manufacturers you have worked with.

- Describe the specific projects you were involved in.

- Highlight your contributions and achievements.

- Explain how your experiences have prepared you for this role.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shoe Parts Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shoe Parts Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Shoe Parts Molders are responsible for operating a variety of molding machines to produce shoe parts. They are typically responsible for the following tasks:

1. Preparing and setting up the molding machine

This includes installing the appropriate mold, setting the machine parameters, and ensuring that the machine is properly calibrated.

2. Operating the molding machine

This involves loading the machine with the appropriate materials, starting the machine, and monitoring the molding process to ensure that the parts are produced to the correct specifications.

3. Inspecting the molded parts

This involves checking the parts for defects and ensuring that they meet the required quality standards.

4. Maintaining and repairing the molding machine

This involves cleaning the machine, performing routine maintenance, and repairing any minor problems that may arise.

Interview Tips

Preparing for an interview for a Shoe Parts Molder position can be challenging, but with the right preparation, you can increase your chances of success.

1. Research the company and the position

Make sure you understand the company’s history, products, and culture. You should also take the time to learn about the specific job responsibilities and qualifications required for the position.

2. Practice your answers to common interview questions

Some common interview questions that you may be asked include:

- Tell me about your experience in operating molding machines.

- What are your quality control standards?

- How do you handle problems that may arise during the molding process?

3. Be prepared to talk about your skills and experience

Make sure you highlight your skills and experience in operating molding machines, inspecting molded parts, and maintaining and repairing equipment. You should also be prepared to talk about your safety record.

4. Dress professionally and be on time for your interview

First impressions are important, so make sure you dress professionally and arrive for your interview on time. This will show the interviewer that you are serious about the position and that you respect their time.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Shoe Parts Molder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Shoe Parts Molder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.