Are you gearing up for a career in Shoemaker Apprentice? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Shoemaker Apprentice and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

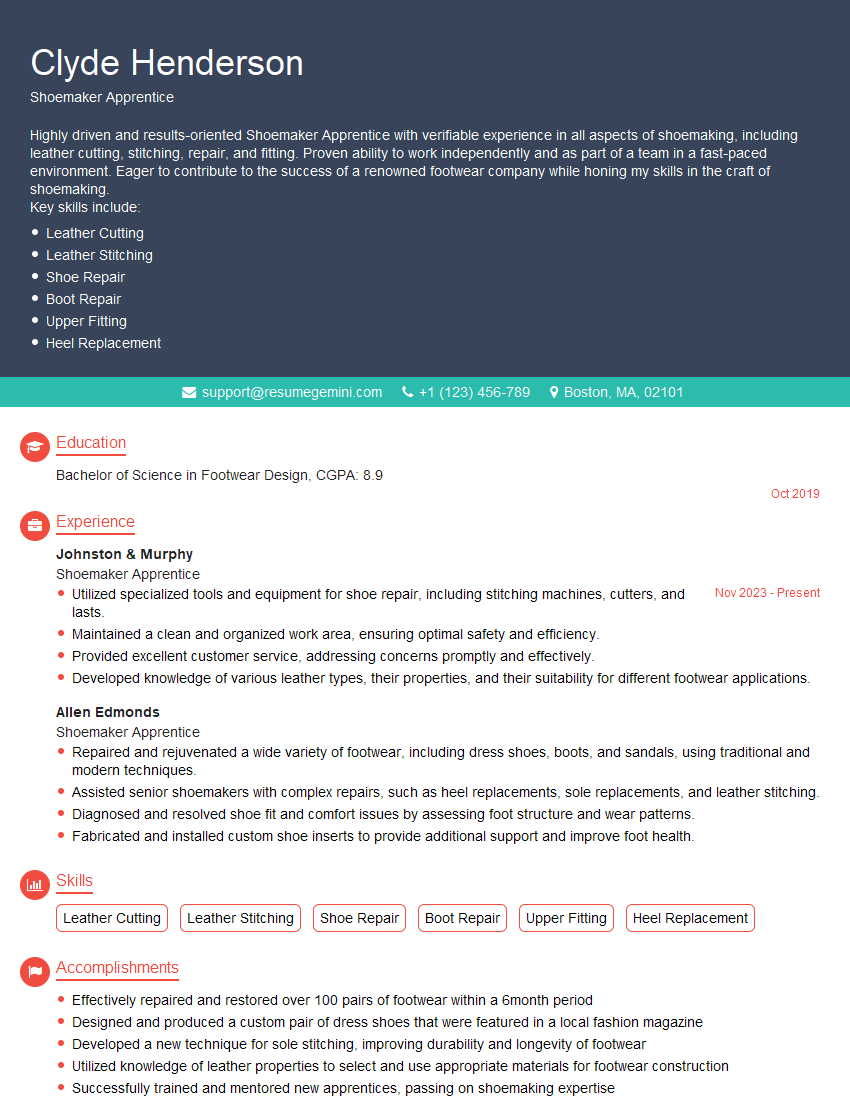

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shoemaker Apprentice

1. Describe the process of taking accurate shoe measurements?

To take accurate shoe measurements, I follow a step-by-step process that ensures a precise fit:

- Foot length: I measure the distance from the heel to the longest toe while the individual stands upright with their weight evenly distributed on both feet.

- Foot width: I measure the widest part of the foot, typically across the ball of the foot.

- Heel-to-ball length: I measure from the heel to the ball of the foot to determine arch height and foot structure.

2. Explain the different types of leather used in shoemaking and their characteristics?

Full-Grain Leather

- Most durable and expensive type of leather

- Retains its natural grain and markings

- Ages gracefully and develops a patina over time

Top-Grain Leather

- Slightly less durable than full-grain leather

- Has a corrected grain surface to remove imperfections

- Still a high-quality and durable option

Split Leather

- Made from the lower layers of the hide

- Less durable and affordable than full-grain or top-grain leather

- Often used for linings and inner soles

Suede

- Made from the underside of the hide

- Soft and velvety texture

- Requires more care and maintenance

3. Discuss the techniques for achieving a secure and durable stitch in shoemaking?

To achieve a secure and durable stitch in shoemaking, I employ the following techniques:

- Needle selection: Choosing the correct needle size and type ensures the leather is punctured cleanly without tearing.

- Thread tension: Proper thread tension is crucial to prevent the stitch from breaking or becoming loose.

- Stitching technique: Using the appropriate stitching technique, such as the saddle stitch or lock stitch, provides strength and durability.

- Knotting: Securely knotting the thread at the beginning and end of each stitch prevents the stitch from unraveling.

4. Describe the methods for creating and attaching a welt in shoemaking?

To create and attach a welt in shoemaking, I follow these steps:

- Cutting: Cutting the welt strip from a suitable leather and shaping it to match the circumference of the shoe.

- Attaching to the upper: Stitching the welt strip to the upper part of the shoe, creating a secure and flexible connection.

- Attaching to the sole: Using adhesives or stitching to attach the welt to the sole, forming a waterproof and durable seal.

5. Explain the process of lasting a shoe and the importance of proper fit?

Lasting a shoe involves shaping the leather upper around a last (a form of the foot) and attaching it to the sole. Proper fit is essential for both comfort and durability:

- Foot support: A properly lasted shoe provides adequate support for the foot, reducing fatigue and discomfort.

- Shape retention: Lasting helps the shoe retain its shape over time, preventing it from becoming deformed or loose.

- Durability: Correct lasting techniques enhance the shoe’s overall durability by ensuring the upper and sole are securely bonded together.

6. Discuss the techniques for finishing and polishing shoes to achieve a professional appearance?

To achieve a professional finish and polish on shoes, I follow a meticulous process:

- Cleaning: Removing any dirt or debris from the shoe using gentle cleaning products.

- Conditioning: Applying leather conditioner to nourish and protect the leather.

- Polishing: Using appropriate polishes and brushes to create a smooth and glossy finish.

- Buffing: Buffing the shoe with a soft cloth or brush to remove excess polish and reveal a brilliant shine.

7. Describe your experience in repairing and restoring damaged shoes?

Throughout my experience as a Shoemaker Apprentice, I have gained proficiency in repairing and restoring damaged shoes:

- Sole repair: Replacing worn or damaged soles to restore the shoe’s functionality and structural integrity.

- Heel repair: Repairing or replacing damaged heels to maintain stability and comfort.

- Leather repair: Mending rips or tears in the leather upper, restoring its appearance and durability.

- Hardware replacement: Replacing damaged or missing buckles, zippers, or other hardware to ensure proper function.

8. Discuss the importance of understanding customer needs and preferences in shoemaking?

Comprehending customer needs and preferences is paramount in shoemaking for several reasons:

- Tailored designs: Understanding customers’ specific requirements allows for creating shoes that meet their unique needs, whether it’s a particular style, fit, or functionality.

- Customer satisfaction: Fulfilling customer expectations enhances their satisfaction and builds long-lasting relationships.

- Problem-solving: Identifying and addressing customers’ concerns enables effective problem-solving and ensures their needs are met.

9. Explain the use of different tools and machinery in shoemaking and their specific functions?

In shoemaking, various tools and machinery are utilized to perform specific tasks:

- Cutting tools: Knives, scissors, and hole punches are used to cut and shape leather and other materials.

- Stitching machines: These machines facilitate precise and efficient stitching, ensuring the durability of the shoe.

- Lasting machines: Used to shape the shoe upper around the last and attach it to the sole.

- Trimming machines: Remove excess material and smooth edges for a clean and professional finish.

10. Describe your knowledge of shoemaking materials and their properties?

As a Shoemaker Apprentice, I have gained a comprehensive understanding of various shoemaking materials:

- Leather: Familiar with different leather types (e.g., full-grain, top-grain, suede) and their characteristics, including durability, breathability, and aesthetics.

- Rubber and plastics: Knowledgeable about the properties and uses of rubber and plastic materials, such as outsoles, midsoles, and heel counters.

- Threads and adhesives: Understanding the strength, elasticity, and durability of different threads and adhesives used in shoemaking.

- Hardware: Familiar with the types and functions of hardware, including buckles, zippers, eyelets, and lacing systems.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shoemaker Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shoemaker Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Shoemaker Apprentice works under a qualified shoemaker to learn to craft, repair, and refinish footwear. Here are some key responsibilities:

1. Footwear Construction

Learn and assist in the construction of shoes and boots, using traditional and modern techniques

- Cut and prepare leather and other materials

- Assemble and sew shoe components

- Add hardware and decorative elements

2. Footwear Repair

Help repair and restore damaged shoes and boots

- Diagnose and assess the damage

- Repair tears, holes, and other defects

- Replace soles, heels, and other parts

3. Footwear Refinishing

Clean, condition, and refinish shoes and boots to improve their appearance

- Remove dirt, stains, and scratches

- Apply polish and protectants

- Repolish and restore the luster of shoes

4. Customer Service

Provide excellent customer service and assist customers in choosing and purchasing footwear

- Greet and assist customers

- Answer questions about footwear

- Process sales and handle complaints

Interview Tips

Preparing for an interview as a Shoemaker Apprentice can help you make a strong impression and increase your chances of getting the job. Here are some tips:

1. Research the Company and Role

Learn about the shoemaker’s business, their values, and their products. Understand the specific duties and responsibilities of the Shoemaker Apprentice role. This shows that you’re interested in the company and the position.

- Visit the company’s website and social media pages

- Read industry news and articles

- Talk to people who work in the shoe industry

2. Practice Your Skills

Demonstrate your skills and knowledge related to shoemaking. You can practice at home or take a workshop. This will give you confidence during the interview.

- Cut and sew leather

- Repair damaged shoes

- Refinish and polish shoes

3. Prepare for Common Interview Questions

Research common interview questions for Shoemaker Apprentices. Prepare your answers and practice delivering them clearly and concisely. This will help you stay calm and collected during the interview.

- Why are you interested in becoming a Shoemaker Apprentice?

- What skills and experience do you have that make you a good fit for this role?

- How do you handle customer service situations?

4. Dress Professionally and Be Punctual

Make a good impression by dressing professionally and arriving on time for your interview. This shows that you’re respectful of the interviewer’s time and that you take the position seriously.

- Wear clean and pressed clothing

- Arrive 5-10 minutes early for your interview

- Bring a portfolio of your work if possible

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Shoemaker Apprentice interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!