Feeling lost in a sea of interview questions? Landed that dream interview for Shot Tube Machine Tender but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Shot Tube Machine Tender interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

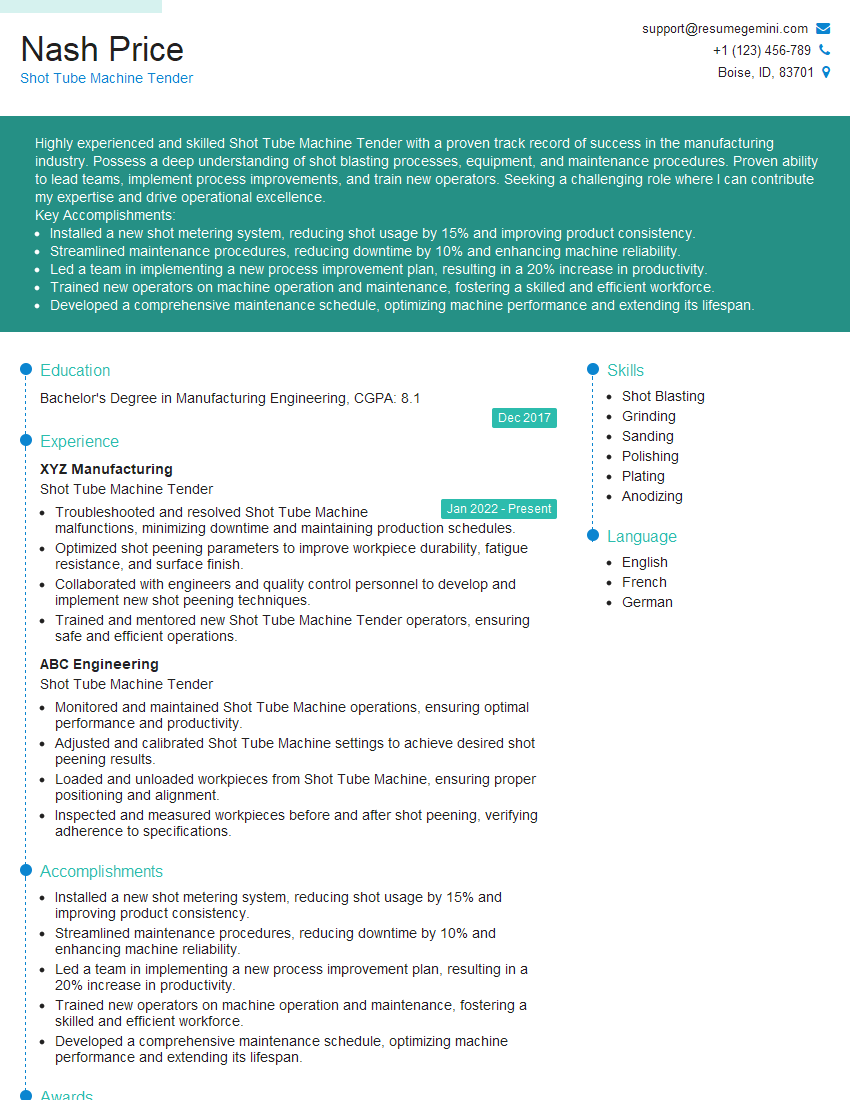

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shot Tube Machine Tender

1. Explain the steps involved in setting up a shot tube machine?

Setting up a shot tube machine involves the following steps:

- Load the shot tubes: The shot tubes are loaded with the required amount of shot material.

- Position the shot tubes: The shot tubes are positioned in the machine’s shot chamber.

- Set the shot parameters: The shot parameters, such as the shot speed, shot angle, and shot frequency, are set according to the desired shot peening effect.

- Start the shot blasting process: The machine is started, and the shot blasting process is initiated.

2. How do you monitor the shot tube machine during operation?

Monitoring shot flow

- Visual inspection: The shot flow is visually inspected to ensure that it is smooth and consistent.

- Sensors: Sensors are used to monitor the shot flow and detect any anomalies.

Monitoring shot quality

- Regular sampling: Shot samples are taken regularly and analyzed to assess the shot quality.

- Microscopic examination: The shot particles are examined under a microscope to determine their size, shape, and hardness.

3. Describe the safety procedures that must be followed when operating a shot tube machine?

The following safety procedures must be followed when operating a shot tube machine:

- Wear appropriate PPE: Safety glasses, earplugs, and gloves must be worn to protect against shot particles and noise.

- Inspect the machine: The machine should be inspected before each use to ensure that it is in good working condition.

- Clear the work area: The work area should be cleared of any obstacles or loose items.

- Follow the operating procedures: The machine’s operating procedures must be followed carefully.

4. How do you troubleshoot common problems that may occur with a shot tube machine?

Common problems that may occur with a shot tube machine and their troubleshooting steps include:

- Reduced shot flow: Check the shot supply, clean the shot lines, and inspect the shot nozzle.

- Uneven shot coverage: Adjust the shot parameters, check the position of the shot tubes, and inspect the shot nozzle.

- Excessive shot consumption: Analyze the shot samples, inspect the shot nozzle, and check the shot recovery system.

- Machine vibration: Check the machine’s mounting, balance the shot wheel, and inspect the bearings.

5. What are the maintenance tasks that need to be performed on a shot tube machine?

Regular maintenance tasks for a shot tube machine include:

- Cleaning: The machine’s exterior, shot chamber, and shot lines should be cleaned regularly.

- Lubrication: The machine’s bearings and moving parts should be lubricated according to the manufacturer’s instructions.

- Inspection: The machine should be inspected regularly for wear and tear, and any damaged components should be replaced.

- Calibration: The shot parameters should be calibrated periodically to ensure optimal performance.

6. What are the quality control procedures involved in shot peening?

Quality control procedures for shot peening include:

- Visual inspection: The peened surface is visually inspected for any defects or uneven coverage.

- Hardness testing: The hardness of the peened surface is tested to ensure that the desired level of surface hardening has been achieved.

- Residual stress measurement: The residual stress in the peened surface is measured to assess the effectiveness of the shot peening process.

- Fatigue testing: Fatigue tests are conducted to evaluate the fatigue life of the peened components.

7. What are the different types of shot peening techniques?

Different types of shot peening techniques include:

- Air blast shot peening: Shot is propelled by compressed air and directed onto the workpiece.

- Wheel blast shot peening: Shot is thrown from a rapidly rotating wheel onto the workpiece.

- Centrifugal blast shot peening: Shot is fed into a spinning impeller and thrown onto the workpiece.

- Gas blast shot peening: Shot is propelled by a gas stream and directed onto the workpiece.

8. How do you select the appropriate shot material for a shot peening application?

The appropriate shot material for a shot peening application is selected based on the following factors:

- Desired surface finish: Different shot materials produce different surface finishes.

- Workpiece material: The shot material should be compatible with the workpiece material.

- Shot size: The shot size should be selected based on the desired level of surface hardening.

- Cost: The cost of the shot material should be considered.

9. What are the benefits of shot peening?

The benefits of shot peening include:

- Improved fatigue life: Shot peening induces compressive residual stresses in the surface of the workpiece, which reduces crack initiation and propagation.

- Increased surface hardness: Shot peening work-hardens the surface of the workpiece, making it more resistant to wear and tear.

- Reduced stress concentration: Shot peening smooths out surface imperfections, reducing stress concentrations that could lead to failure.

- Improved corrosion resistance: Shot peening creates a dense and protective surface layer that is less susceptible to corrosion.

10. What are the applications of shot peening?

Shot peening is used in a wide range of industries and applications, including:

- Automotive: Shot peening is used to improve the fatigue life and wear resistance of automotive components such as gears, springs, and connecting rods.

- Aerospace: Shot peening is used to enhance the fatigue life of aircraft components such as turbines, blades, and landing gear.

- Medical: Shot peening is used to improve the surface finish and wear resistance of medical implants.

- Manufacturing: Shot peening is used to strengthen and improve the surface finish of metal products such as tools, dies, and molds.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shot Tube Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shot Tube Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Shot Tube Machine Tenders execute intricate tasks in the manufacturing process, ensuring the smooth operation of specialized machinery, maintaining safety standards, and consistent product quality.

1. Machine Operation

The Shot Tube Machine Tender is the primary operator of the shot tube machine, responsible for its precise functioning. Their key responsibilities include:

- Loading and unloading raw materials, monitoring feed rates, and adjusting machine settings to optimize production efficiency.

- Supervising all aspects of the machine’s operation, identifying and resolving any mechanical issues or malfunctions promptly.

2. Quality Control

Shot Tube Machine Tenders play a vital role in ensuring the quality of the final product. Their key responsibilities include:

- Conducting regular inspections and tests on the machine and its components, maintaining accuracy and consistency in production.

- Monitoring product quality, conducting visual inspections, and collecting data to identify and correct any deviations from established standards.

3. Process Optimization

Shot Tube Machine Tenders are expected to identify areas for process improvement. Their key responsibilities include:

- Analyzing production data, identifying bottlenecks, and suggesting modifications to enhance machine efficiency and productivity.

- Collaborating with engineers to develop and implement process improvements, leading to reduced costs and increased output.

4. Safety and Maintenance

Shot Tube Machine Tenders are responsible for ensuring a safe and well-maintained work environment. Their key responsibilities include:

- Adhering to established safety protocols, wearing appropriate protective gear, and promoting a safe working environment for themselves and colleagues.

- Performing regular maintenance tasks, cleaning, lubricating, and inspecting the machine to ensure its optimal performance and longevity.

Interview Tips

To ace the interview for a Shot Tube Machine Tender position, candidates should prepare thoroughly by:

1. Research the Company and Role

Understanding the company’s culture, values, and the specific requirements of the role is crucial. Research the company’s website, LinkedIn page, and industry news to gain insights into the organization and the position you are applying for.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills related to shot tube machine operation, quality control, and process optimization. Quantify your accomplishments and provide specific examples of your contributions to previous projects or roles.

3. Practice Common Interview Questions

Anticipate and prepare for common interview questions related to your skills, experience, and motivations. Practice answering these questions clearly and concisely, highlighting your strengths and how they align with the job requirements.

4. Prepare Industry-Specific Questions

Demonstrate your knowledge of the shot tube manufacturing industry by asking informed questions about the company’s production processes, quality standards, or safety protocols. This shows your enthusiasm and eagerness to learn.

5. Emphasize Safety and Attention to Detail

Safety and attention to detail are paramount in this role. Highlight your commitment to following established procedures, conducting thorough inspections, and maintaining a clean and organized work environment.

6. Show Enthusiasm and Eagerness to Learn

Express your passion for manufacturing and your dedication to continuous learning. Show that you are eager to contribute to the team and take on new challenges.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Shot Tube Machine Tender, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Shot Tube Machine Tender positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.