Are you gearing up for an interview for a Shotblaster position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Shotblaster and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

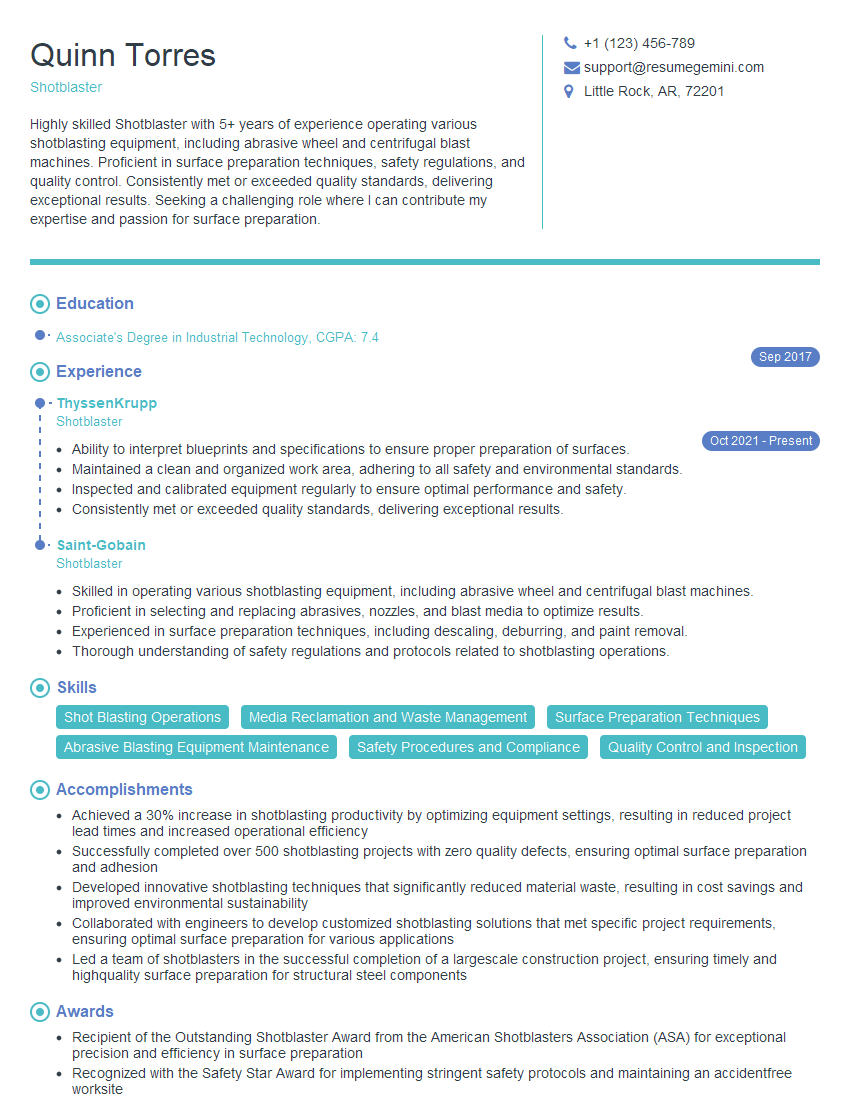

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shotblaster

1. Describe the different types of shot blasting equipment and their applications?

Shot blasting equipment can be classified into two main types: air-blast and wheel-blast. Air-blast equipment uses compressed air to propel abrasive particles at high speed onto the surface to be cleaned or prepared. Wheel-blast equipment uses a rotating impeller to throw abrasive particles at the surface.

- Air-blast equipment is typically used for smaller-scale operations, such as cleaning and deburring small parts in the automotive industry.

- Wheel-blast equipment is typically used for larger-scale operations, such as cleaning and preparing structural steel in the construction industry.

2. Explain the different types of abrasives used in shot blasting and their advantages and disadvantages?

- Steel shot is the most common abrasive used in shot blasting. It is a hard and durable material that can be used to remove rust, paint, and other coatings from a variety of surfaces.

- Steel grit is a crushed steel product that is used for heavier-duty applications. It is more aggressive than steel shot and can be used to remove thicker coatings and heavier rust.

- Glass beads are a softer abrasive that is used for more delicate applications. They are not as aggressive as steel shot or grit, but they can be used to clean and polish surfaces without damaging them.

3. Describe the process of shot blasting and the different parameters that can be controlled to achieve the desired results?

The shot blasting process involves directing a stream of abrasive particles at high speed onto the surface to be cleaned or prepared.

- The size of the abrasive particles determines the aggressiveness of the blasting process. Larger particles will remove more material faster, but they can also damage delicate surfaces.

- The flow rate of the abrasive particles determines the coverage of the blasting process. A higher flow rate will cover a larger area faster, but it can also lead to over-blasting.

- The angle at which the abrasive particles are directed determines the finish of the blasted surface. A perpendicular angle will produce a rougher finish, while an oblique angle will produce a smoother finish.

- The distance between the nozzle and the surface determines the intensity of the blasting process. A closer distance will produce a more intense blast, while a longer distance will produce a less intense blast.

4. Explain the safety precautions that must be taken when operating shot blasting equipment?

- Wear appropriate personal protective equipment (PPE), including a respirator, gloves, eye protection, and hearing protection.

- Operate the equipment in a well-ventilated area to prevent the inhalation of abrasive dust.

- Keep the equipment in good working order and inspect it regularly for any signs of damage.

- Follow the manufacturer’s instructions for operating the equipment.

5. Describe the different methods of shot blasting and their advantages and disadvantages?

- Manual shot blasting is a method in which the operator directs the abrasive stream manually. This method is more labor-intensive, but it allows for more precise control of the blasting process.

- Automated shot blasting is a method in which the abrasive stream is directed by a robot or other automated device. This method is less labor-intensive, but it can be more difficult to control the blasting process.

6. What are the different types of surface finishes that can be achieved with shot blasting?

- A rough finish is typically used for surfaces that will be painted or coated.

- A smooth finish is typically used for surfaces that will be left uncoated.

- A matte finish is a finish that is between a rough finish and a smooth finish.

7. What are the typical applications of shot blasting?

- Cleaning and preparing metal surfaces for painting or coating.

- Removing rust and corrosion from metal surfaces.

- Deburring and smoothing metal edges.

- Preparing surfaces for welding.

8. What are the advantages of shot blasting over other surface preparation methods?

- Shot blasting is a fast and efficient method of surface preparation.

- Shot blasting can be used on a variety of surfaces, including metal, concrete, and wood.

- Shot blasting is a relatively inexpensive method of surface preparation.

9. What are the disadvantages of shot blasting?

- Shot blasting can be noisy and generate dust.

- Shot blasting can damage delicate surfaces if not properly controlled.

- Shot blasting can be hazardous if not operated properly.

10. What are the trends in the shot blasting industry?

- The use of automated shot blasting systems is increasing.

- The development of new abrasive materials is improving the efficiency and effectiveness of shot blasting.

- The use of shot blasting is expanding into new industries, such as the automotive industry and the aerospace industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shotblaster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shotblaster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Shotblasters play a crucial role in the surface preparation and treatment industry, ensuring the quality and durability of metal surfaces. Their primary duties involve operating and maintaining shot blasting machines to clean, prepare, and enhance the surfaces of various metal objects.

1. Surface Preparation

- Operate shot blasting machines to remove rust, paint, scale, and other contaminants from metal surfaces.

- Adjust machine settings to ensure optimal cleaning results based on the type of surface and the desired finish.

2. Equipment Operation and Maintenance

- Operate shot blasting machines safely and efficiently, following established safety protocols.

- Perform routine maintenance checks on the machine, including cleaning, lubrication, and component replacement.

- Identify and troubleshoot any equipment malfunctions promptly to minimize downtime.

3. Quality Control

- Inspect blasted surfaces to ensure they meet specified quality standards for cleanliness and finish.

- Maintain records of blasting parameters and surface conditions to ensure consistency and traceability.

4. Safety Compliance

- Adhere to all safety regulations related to shot blasting operations, including wearing appropriate protective gear and following designated work procedures.

- Maintain a clean and organized work area to minimize potential hazards.

Interview Tips

To ace a shotblaster interview, candidates should prepare thoroughly and demonstrate their knowledge, skills, and commitment to safety.

1. Research the Industry and Company

- Familiarize yourself with the shot blasting industry, its applications, and the specific products or services offered by the company.

- Research the company’s safety practices and their commitment to quality.

2. Highlight Relevant Skills and Experience

- Emphasize your experience in operating and maintaining shot blasting machines.

- Highlight your knowledge of surface preparation techniques, quality control procedures, and safety protocols.

- Provide examples of your ability to work independently, troubleshoot problems, and meet deadlines.

3. Prepare for Technical Questions

- Review basic shot blasting principles, including machine types, abrasives, and surface preparation techniques.

- Be prepared to answer questions about equipment maintenance and troubleshooting.

- Demonstrate your understanding of safety precautions and regulations.

4. Practice Common Interview Questions

- Rehearse answers to common interview questions such as “Tell me about yourself,” “Why are you interested in this position,” and “What are your strengths and weaknesses.”

- Prepare examples of your work experience that showcase your skills and abilities.

5. Dress Professionally and Arrive Punctually

- Dress appropriately for the interview, adhering to the company’s dress code or professional standards.

- Arrive on time for your interview to demonstrate your punctuality and respect for the interviewer’s time.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Shotblaster role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.