Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Shotgun Shell Assembly Machine Adjuster position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

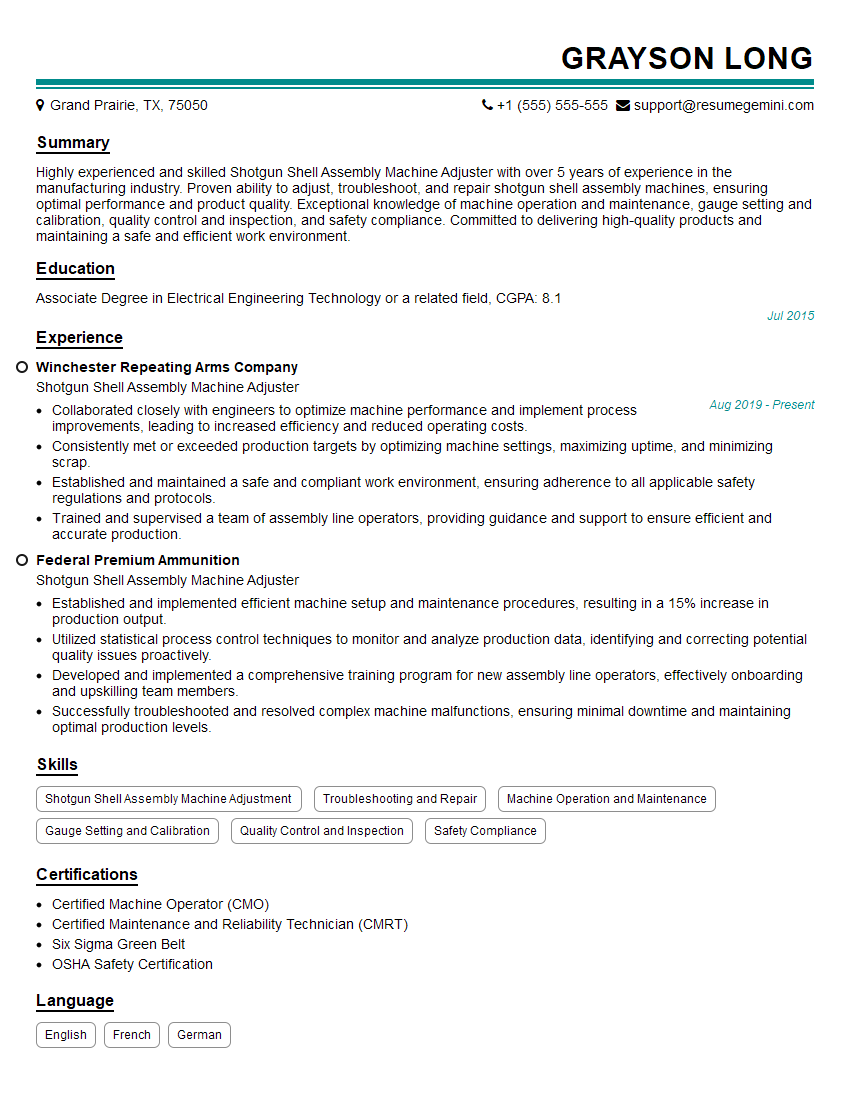

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shotgun Shell Assembly Machine Adjuster

1. Explain the process of adjusting the powder drop on a shotgun shell assembly machine.

The powder drop on a shotgun shell assembly machine is adjusted to ensure that the correct amount of powder is dispensed into each shell. This process involves the following steps:

- Checking the powder level in the hopper and adding more powder if necessary.

- Adjusting the powder drop height to ensure that the powder is dispensed at the correct level.

- Adjusting the powder drop speed to ensure that the powder is dispensed at the correct rate.

- Testing the powder drop by dispensing several shells and weighing the powder in each shell to ensure that it is within the specified tolerance.

2. Describe the different types of wads used in shotgun shells and their functions.

Types of wads used in shotgun shells:

- Over powder wad

- Shot wad

- Filler wad

- Over shot wad

Functions of wads:

- Over powder wad: Protects the powder from the heat of the primer and helps to create a gas seal.

- Shot wad: Holds the shot in place and protects the shot from the heat of the powder.

- Filler wad: Fills the space between the shot wad and the over shot wad and helps to keep the shot in place.

- Over shot wad: Protects the shot from the elements and helps to keep the shot in place.

3. Explain the process of crimping a shotgun shell.

Crimping a shotgun shell involves the following steps:

- Placing the shell in the crimping machine.

- Adjusting the crimping machine to the correct settings for the shell size and type.

- Crimping the shell by applying pressure to the shell with the crimping dies.

- Inspecting the crimped shell to ensure that it is properly crimped.

4. Describe the different types of defects that can occur during shotgun shell assembly and how to correct them.

Types of defects that can occur during shotgun shell assembly:

- Powder drop problems

- Wad alignment problems

- Crimping problems

- Shell length problems

How to correct defects:

- Powder drop problems: Adjust the powder drop height and speed.

- Wad alignment problems: Adjust the wad guide.

- Crimping problems: Adjust the crimping machine settings.

- Shell length problems: Adjust the shell length gauge.

5. Explain the importance of maintaining a clean and well-lubricated shotgun shell assembly machine.

Maintaining a clean and well-lubricated shotgun shell assembly machine is important for several reasons:

- Prevents wear and tear on the machine.

- Prevents breakdowns and keeps the machine running smoothly.

- Ensures that the machine produces high-quality shotgun shells.

6. Describe the safety precautions that should be taken when working with shotgun shell assembly machines.

The following safety precautions should be taken when working with shotgun shell assembly machines:

- Wear appropriate safety gear, including safety glasses, earplugs, and gloves.

- Keep hands away from moving parts.

- Never operate the machine with the guards removed.

- Be aware of the location of the emergency stop button.

- Follow all manufacturer’s instructions for safe operation.

7. Explain the importance of teamwork in a shotgun shell assembly operation.

Teamwork is important in a shotgun shell assembly operation for several reasons:

- It ensures that all tasks are completed efficiently and on time.

- It helps to prevent errors and ensure that high-quality shotgun shells are produced.

- It fosters a positive and productive work environment.

8. Describe your experience with troubleshooting shotgun shell assembly machines.

I have experience troubleshooting a variety of problems with shotgun shell assembly machines, including:

- Powder drop problems

- Wad alignment problems

- Crimping problems

- Shell length problems

- Machine breakdowns

I am able to quickly identify the source of the problem and take corrective action to get the machine running again as quickly as possible.

9. Explain how you would train a new employee on how to operate a shotgun shell assembly machine.

I would train a new employee on how to operate a shotgun shell assembly machine by following these steps:

- Review the manufacturer’s instructions for the machine.

- Demonstrate how to operate the machine safely and efficiently.

- Have the new employee practice operating the machine under my supervision.

- Answer any questions that the new employee may have.

- Observe the new employee operating the machine on their own to ensure that they are able to do so safely and efficiently.

10. What are your career goals?

My career goals are to become a skilled and experienced Shotgun Shell Assembly Machine Adjuster. I am confident that I have the skills and experience necessary to be successful in this role. I am eager to learn and grow my skills, and I am committed to working hard and contributing to the success of your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shotgun Shell Assembly Machine Adjuster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shotgun Shell Assembly Machine Adjuster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Shotgun Shell Assembly Machine Adjuster is responsible for setting up, adjusting, and maintaining shotgun shell assembly machines to ensure optimal performance and efficiency.

1. Equipment Setup and Maintenance

Installs, adjusts, and calibrates shotgun shell assembly machines according to manufacturer specifications.

- Conducts routine inspections and preventive maintenance to identify and resolve potential issues.

- Troubleshoots and repairs mechanical and electrical malfunctions to minimize downtime.

2. Process Optimization

Monitors and analyzes machine performance to identify areas for improvement.

- Adjusts machine settings and parameters to optimize production speed, accuracy, and quality.

- Conducts experiments and research to develop new and innovative solutions.

3. Quality Control

Inspects and verifies the quality of shotgun shells produced by the machines.

- Ensures that shells meet specifications and standards by performing visual and dimensional inspections.

- Identifies and resolves any defects or inconsistencies in the production process.

4. Training and Supervision

Provides training to new operators on the operation and maintenance of shotgun shell assembly machines.

- Supervises and mentors operators to ensure adherence to safety protocols and work instructions.

- Coordinates with other departments to ensure seamless production and quality control.

Interview Tips

Preparing for an interview for a Shotgun Shell Assembly Machine Adjuster position requires a combination of technical knowledge and a strong understanding of the industry. Here are some tips and hacks to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and mission. Understand the shotgun shell manufacturing industry, including market trends and competitive landscapes.

- This demonstrates your interest in the position and shows that you’ve taken the time to learn about the company and the industry.

- Example: “I was impressed by your company’s commitment to innovation and sustainability in the shotgun shell industry.”

2. Highlight Your Technical Skills

Emphasize your experience in setting up, adjusting, and maintaining shotgun shell assembly machines. Quantify your accomplishments and provide specific examples of how you have optimized production.

- Use numbers and metrics to support your claims. This will help the interviewer assess your technical abilities and past performance.

- Example: “In my previous role, I successfully increased production efficiency by 15% through process optimization and machine fine-tuning.”

3. Showcase Your Quality Control Expertise

Demonstrate your understanding of shotgun shell quality standards and inspection procedures. Explain how you ensure that shells meet specifications and identify and resolve any defects.

- This will highlight your attention to detail and commitment to producing high-quality products.

- Example: “I have developed and implemented a comprehensive quality control program that has significantly reduced defect rates and improved customer satisfaction.”

4. Prepare for Behavioral Questions

In addition to technical questions, you should also prepare for behavioral questions that assess your teamwork, problem-solving, and communication skills.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Example: “Tell me about a time when you faced a challenging machine malfunction. How did you troubleshoot and resolve the issue?”

5. Ask Thoughtful Questions

At the end of the interview, ask insightful questions that demonstrate your interest in the position and the company. This shows that you are engaged and keen on learning more.

- Questions could focus on the company’s growth plans, new product development, or industry trends.

- Example: “What are the company’s strategic initiatives for the upcoming year, and how do you see the Shotgun Shell Assembly Machine Adjuster role contributing to those goals?”

Next Step:

Now that you’re armed with the knowledge of Shotgun Shell Assembly Machine Adjuster interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Shotgun Shell Assembly Machine Adjuster positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini