Are you gearing up for an interview for a Shoulder Pad Molder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Shoulder Pad Molder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

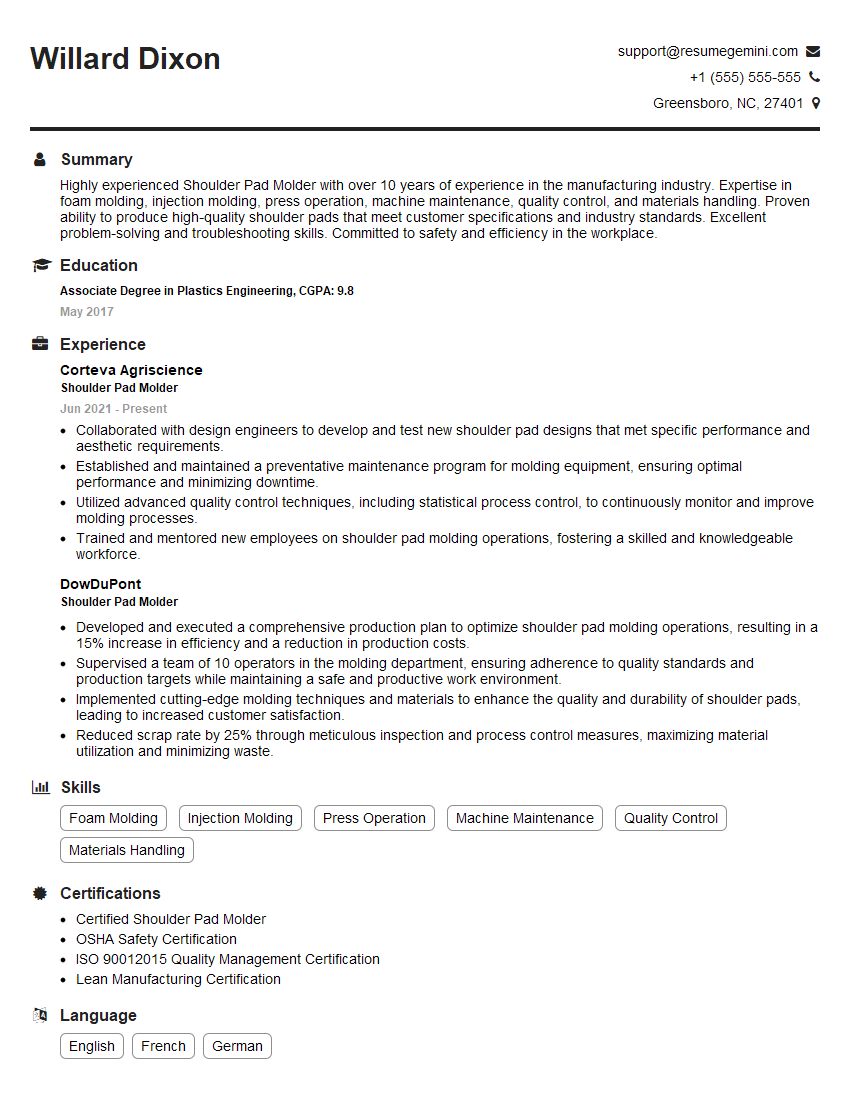

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shoulder Pad Molder

1. Interview question: Describe the steps involved in molding shoulder pads?

Answer: – Prepare the mold by cleaning and applying a release agent. – Cut and place the fabric or foam material into the mold. – Heat the mold to the desired temperature. – Apply pressure to the mold to form the shoulder pad. – Cool the mold and remove the shoulder pad. – Inspect and trim the shoulder pad to meet specifications.

2. Interview question: What types of materials are used in shoulder pad molding?

Answer: – Fabrics (e.g., nylon, polyester, cotton) – Foams (e.g., polyurethane, polyethylene) – Adhesives (e.g., hot melt, solvent-based) – Reinforcements (e.g., interlining, webbing)

3. Interview question: How do you ensure the quality of molded shoulder pads?

Answer: – Inspect raw materials for defects. – Calibrate and maintain molding equipment regularly. – Follow established molding procedures. – Perform visual and dimensional inspections of finished products. – Implement statistical process control (SPC) techniques.

4. Interview question: What are the common defects in shoulder pad molding and how do you prevent them?

Answer: – Wrinkles or folds: Use proper tension when placing the material in the mold and apply even pressure. – Air bubbles: Ensure the mold is properly degassed before molding. – Uneven thickness: Calibrate the mold and apply consistent pressure during molding. – Delamination: Use the correct adhesive and apply it evenly.

5. Interview question: How do you optimize the molding process for efficiency and productivity?

Answer: – Use rapid prototyping techniques to reduce mold development time. – Implement automation in the molding process. – Optimize mold design for faster cooling and demolding. – Train and motivate operators to improve performance.

6. Interview question: What are the safety precautions to be taken when working in a shoulder pad molding facility?

Answer: – Wear appropriate safety gear (e.g., gloves, goggles, earplugs). – Handle hazardous materials (e.g., adhesives, solvents) with care. – Be aware of and follow machinery safety guidelines. – Maintain a clean and organized work area.

7. Interview question: How do you stay up-to-date with the latest advancements in shoulder pad molding technology?

Answer: – Attend industry conferences and seminars. – Read trade publications and technical journals. – Network with other shoulder pad manufacturers. – Collaborate with research institutions.

8. Interview question: Describe your experience in troubleshooting and solving molding problems?

Answer: – Problem: Wrinkled shoulder pads due to uneven pressure. – Solution: Adjusted mold pressure settings and ensured uniform pressure distribution. – Problem: Air bubbles trapped in the molded pad. – Solution: Implemented vacuum degassing in the mold.

9. Interview question: What are the challenges and opportunities in the shoulder pad molding industry?

Answer: – Challenges: – Increasing competition from low-cost manufacturers. – Fluctuating raw material prices. – Environmental regulations on hazardous materials. – Opportunities: – Growing demand for customized and high-performance shoulder pads. – Advancements in molding technologies for improved efficiency and quality. – Expansion into new markets (e.g., sports, medical, military).

10. Interview question: Tell us about your motivation for applying for this Shoulder Pad Molder position?

Answer: – Passion for the manufacturing industry, particularly in molding processes. – Interest in the technical aspects of shoulder pad molding. – Desire to contribute to the production of high-quality products. – Eagerness to learn and grow within the company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shoulder Pad Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shoulder Pad Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Shoulder Pad Molder is responsible for operating machinery to mold and shape shoulder pads for garments. Their duties encompass:

1. Molding and Shaping

A Shoulder Pad Molder’s primary task is to manipulate and mold raw materials, such as foam or fabric, into desired shoulder pad shapes.

- Setting up and operating molding machines

- Placing materials into molds and activating the molding process

- Controlling temperature and pressure settings to achieve optimal molding results

- Ensuring the accuracy and consistency of the molded shoulder pads

2. Production Monitoring

They are responsible for monitoring the production process to ensure efficiency and quality control.

- Observing machinery for any malfunctions or irregularities

- Adjusting machine settings as needed to optimize performance

- Inspecting molded shoulder pads for defects and non-conformities

- Maintaining production logs and records

3. Material Handling

Shoulder Pad Molders are responsible for handling and managing raw materials and finished products.

- Loading and unloading materials from storage areas

- Transporting molded shoulder pads to designated locations

- Maintaining organized and clean work areas

- Adhering to safety protocols for handling equipment and materials

4. Equipment Maintenance

They perform basic maintenance and troubleshooting on the molding equipment.

- Cleaning and lubricating machinery

- Inspecting equipment for wear and tear

- Reporting any equipment issues or malfunctions to supervisors

- Following established maintenance schedules

Interview Tips

To ace a job interview for a Shoulder Pad Molder position, it’s imperative to prepare thoroughly and showcase your relevant skills and experience. Here are some interview preparation tips:

1. Research the Company and Role

Familiarize yourself with the company’s history, values, and product line. Research the specific responsibilities of the Shoulder Pad Molder role and identify how your skills align with the requirements.

- Visit the company’s website and LinkedIn page

- Read industry articles and news related to the role

- Network with professionals in the field

2. Highlight Relevant Experience

Emphasize your experience in operating molding machinery and handling materials. Quantify your accomplishments whenever possible and provide specific examples of your contributions.

- Use action verbs to describe your responsibilities

- Provide examples of projects or initiatives where you exceeded expectations

- Quantify your results whenever possible, using specific metrics

3. Demonstrate Quality Control Skills

Interviewers will be eager to assess your commitment to producing high-quality shoulder pads. Highlight your attention to detail, accuracy, and ability to identify and correct defects.

- Discuss your experience in following established quality control standards

- Provide examples of how you have improved production processes to reduce errors

- Emphasize your willingness to go the extra mile to ensure customer satisfaction

4. Prepare for Technical Questions

You may encounter technical questions about molding techniques, equipment maintenance, or production processes. Familiarize yourself with common molding terms and concepts.

- Review basic principles of molding and shaping

- Research different types of molding machines and their applications

- Practice troubleshooting common equipment issues

5. Practice Common Interview Questions

Prepare answers to common interview questions such as “Tell me about yourself,” “Why are you interested in this role,” and “What are your strengths and weaknesses?”.

- Tailor your answers to the specific job requirements

- Use the STAR method (Situation, Task, Action, Result) to structure your responses

- Practice answering questions out loud to build confidence

Next Step:

Now that you’re armed with the knowledge of Shoulder Pad Molder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Shoulder Pad Molder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini