Are you gearing up for a career in Shovel Engineer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Shovel Engineer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

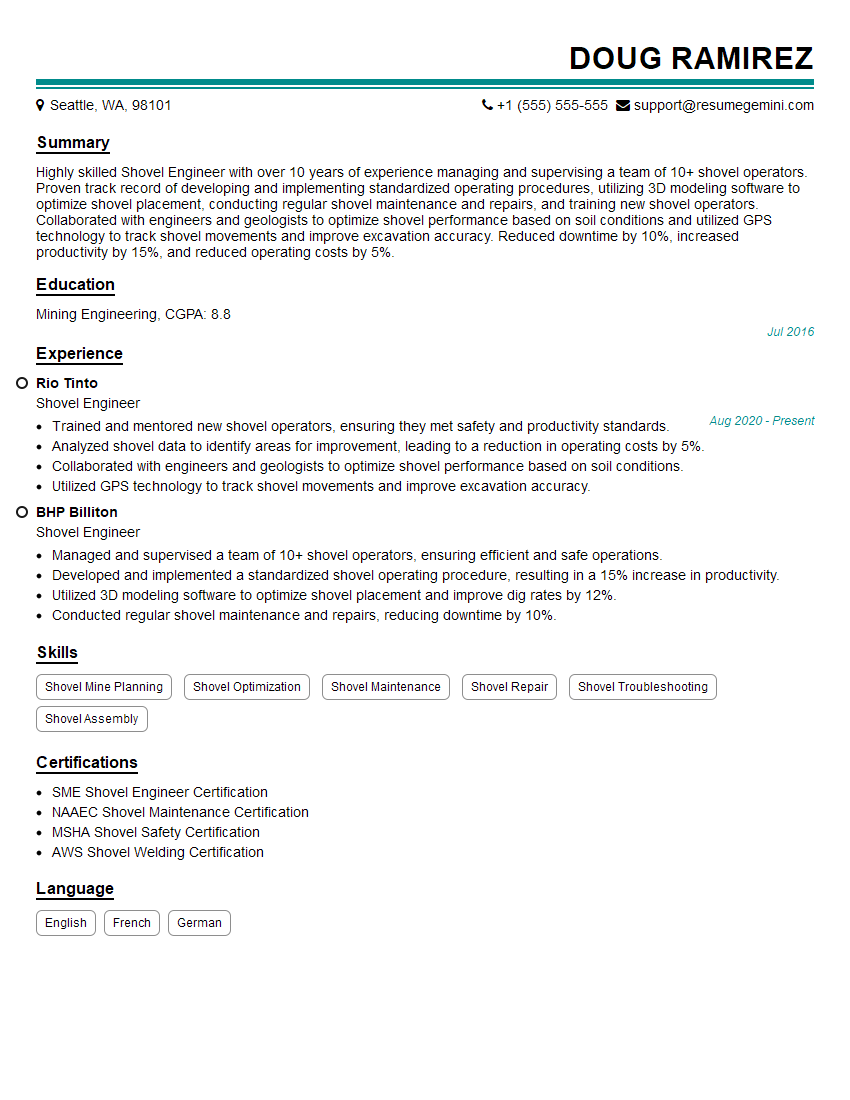

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shovel Engineer

1. Describe the key responsibilities of a Shovel Engineer?

As a Shovel Engineer, my responsibilities encompass the following:

- Planning and scheduling shovel operations to optimize production and efficiency.

- Monitoring shovel performance, identifying areas for improvement, and implementing solutions.

- Inspecting and maintaining shovels to ensure safe and reliable operation.

- Troubleshooting mechanical, electrical, and hydraulic issues promptly and effectively.

- Collaborating with mine planning and production teams to align shovel operations with overall mine goals.

2. Explain the principles of shovel-truck interaction and how it impacts mine productivity?

Shovel-truck interaction plays a crucial role in mine productivity. The following are some key principles:

Matching Shovel Capacity to Truck Capacity

- Ensuring the shovel’s bucket size can efficiently load the trucks without spillage or overburden.

- Optimizing the number of truck passes required to fill each shovel pass.

Haul Road Conditions

- Maintaining optimal haul road conditions to minimize truck cycle times.

- Ensuring the roads are graded and compacted to provide a smooth and safe surface.

Truck Traffic Management

- Implementing traffic management systems to avoid congestion and delays.

- Coordinating truck movements to ensure a steady supply of trucks for loading.

3. Discuss the different types of shovel monitoring systems and their benefits?

There are several types of shovel monitoring systems available, each with its advantages:

- Production Monitoring Systems: Track shovel productivity metrics such as tons loaded, cycle times, and utilization.

- Condition Monitoring Systems: Monitor shovel components for wear and tear, detecting potential failures early.

- Health and Safety Monitoring Systems: Ensure operator safety by monitoring factors like seat belt usage and machine vibration.

- Remote Monitoring Systems: Allow real-time monitoring of shovel operations from remote locations for troubleshooting and support.

4. Describe the procedures involved in troubleshooting a mechanical issue on a shovel?

- Identify the Problem: Observe shovel behavior, listen for unusual sounds, and check for any visible damage.

- Inspect Components: Examine potentially affected components such as hoses, bearings, and hydraulic cylinders.

- Test System: Initiate tests to isolate the issue and identify the specific component causing the problem.

- Repair or Replace: Based on the diagnosis, repair or replace the faulty component.

- Verify Functionality: Conduct a test run to ensure the issue has been resolved.

5. Explain the role of a Shovel Engineer in maximizing fuel efficiency?

- Optimizing Shovel Utilization: Minimizing idle time and ensuring the shovel is operating at its most efficient capacity.

- Monitoring Fuel Consumption: Tracking fuel usage and identifying areas for improvement.

- Implementing Fuel-Saving Techniques: Utilizing technologies like variable speed drives and auto-idle systems to reduce fuel consumption.

- Training Operators: Providing training to operators on fuel-efficient operating practices.

6. Discuss the safety considerations and regulations for operating a shovel?

Safety is paramount when operating a shovel. The following considerations and regulations must be adhered to:

- Pre-Operation Inspections: Conduct thorough inspections before each shift to identify potential hazards.

- Personal Protective Equipment: Wear appropriate PPE such as hard hats, safety glasses, and high-visibility clothing.

- Operator Training: Ensure operators are properly trained and certified to operate the shovel safely.

- Work Zone Safety: Establish and maintain clear work zones to prevent unauthorized access.

- Emergency Procedures: Have clearly defined emergency procedures in place and train operators on their execution.

7. Explain the principles of effective shovel maintenance and its impact on productivity?

Regular and effective shovel maintenance is crucial for preserving productivity and minimizing downtime.

Scheduled Maintenance

- Implement planned maintenance schedules based on manufacturer recommendations and historical data.

- Conduct periodic inspections, lubrication, and adjustments to prevent failures.

Predictive Maintenance

- Utilize condition monitoring systems to identify potential issues before they become major problems.

- Schedule maintenance based on predictive data to prevent unplanned breakdowns.

Impact on Productivity

- Reduced downtime and increased shovel availability.

- Enhanced shovel performance and efficiency.

- Lower maintenance costs in the long run due to early detection and prevention of major repairs.

8. Describe the use of technology in modern shovel operations?

Technology plays a significant role in modern shovel operations:

- Automation: Advanced shovels incorporate automated systems for functions like bucket positioning and swing control.

- Data Analytics: Shovel monitoring systems provide real-time data that can be analyzed to identify performance bottlenecks and optimize operations.

- Remote Monitoring: Remote monitoring systems allow operators to track shovel performance and troubleshoot issues from a central location.

- Simulation: Shovel simulators are used to train operators and test new operating strategies without putting the actual equipment at risk.

9. Discuss the challenges and opportunities in the field of shovel engineering?

Challenges

- Demanding Work Environment: Working in harsh mining conditions with heavy equipment poses physical and mental challenges.

- Continuous Improvement: The constant need to optimize shovel performance and adapt to new technologies.

- Safety Concerns: Ensuring the safe operation of large and powerful machinery.

Opportunities

- Advancement Opportunities: The mining industry offers career growth potential for ambitious engineers.

- Cutting-Edge Technology: Involvement in the development and implementation of innovative shovel technologies.

- Contribution to Sustainable Mining: Optimizing shovel operations to enhance efficiency and reduce environmental impact.

10. Explain how your skills and experience align with the requirements of this Shovel Engineer position?

My technical skills, including a deep understanding of shovel mechanics, electrical systems, and hydraulics, enable me to effectively troubleshoot and maintain shovels to ensure optimal performance. I am proficient in using shovel monitoring systems and data analysis tools to identify areas for improvement and optimize operations.

Furthermore, my experience in planning and scheduling shovel operations, as well as my strong communication and collaboration skills, make me an excellent candidate for this role. I am confident in my ability to contribute to the team’s success and enhance mine productivity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shovel Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shovel Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Shovel Engineer plays a crucial role in the operation and maintenance of large-scale mining equipment, ensuring efficient and productive operations. Here are the key responsibilities of a Shovel Engineer:

1. Operational Proficiency

Skilled operation of shovels, including diesel-electric, hydraulic, and rope shovels.

- Efficiently load and haul materials, ensuring proper bucket fills and optimal cycle times.

- Monitor and adjust shovel parameters such as swing speed, digging depth, and bucket position to maximize productivity.

2. Maintenance and Troubleshooting

Perform routine maintenance and troubleshooting of shovels to prevent breakdowns and ensure smooth operations.

- Identify, diagnose, and repair mechanical, electrical, and hydraulic issues promptly.

- Conduct regular inspections, lubricate components, and replace worn parts.

3. Production Optimization

Collaborate with mine planners and production teams to optimize shovel performance and increase efficiency.

- Analyze production data and identify areas for improvement, such as reducing cycle times or increasing bucket payloads.

- Implement changes to shovel operations and maintenance practices to enhance productivity and reduce downtime.

4. Equipment Management

Manage and maintain a fleet of shovels, ensuring their availability and performance.

- Schedule and coordinate maintenance activities to minimize downtime and maximize equipment lifespan.

- Monitor equipment health, identify potential issues, and initiate preventive maintenance measures.

5. Safety and Compliance

Ensure adherence to safety regulations and company policies related to shovel operations.

- Conduct regular safety inspections, wear appropriate personal protective equipment (PPE), and follow established safety protocols.

- Maintain a clean and organized work area, minimize environmental impact, and report any potential hazards.

Interview Tips

To prepare effectively for a Shovel Engineer interview, consider the following tips:

1. Research the Company and Position

Thoroughly research the mining company and the specific Shovel Engineer position. This will help you understand their operations, culture, and the skills and experience they seek.

2. Practice Your Technical Skills

Review your shovel operating and maintenance knowledge. Practice answering technical questions about shovel systems, troubleshooting techniques, and production optimization strategies.

3. Highlight Your Experience

Quantify your accomplishments and emphasize your relevant experience in operating, maintaining, and optimizing shovels. Use specific examples to demonstrate your proficiency and problem-solving abilities.

4. Be Prepared for Behavioral Questions

Interviewers often ask behavioral questions to assess your work style and interpersonal skills. Prepare for questions about teamwork, conflict resolution, and your approach to safety and compliance.

5. Dress Professionally and Arrive Early

First impressions matter. Dress professionally for your interview and arrive on time to show respect and punctuality.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Shovel Engineer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.