Are you gearing up for a career in Shovel Oiler? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Shovel Oiler and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

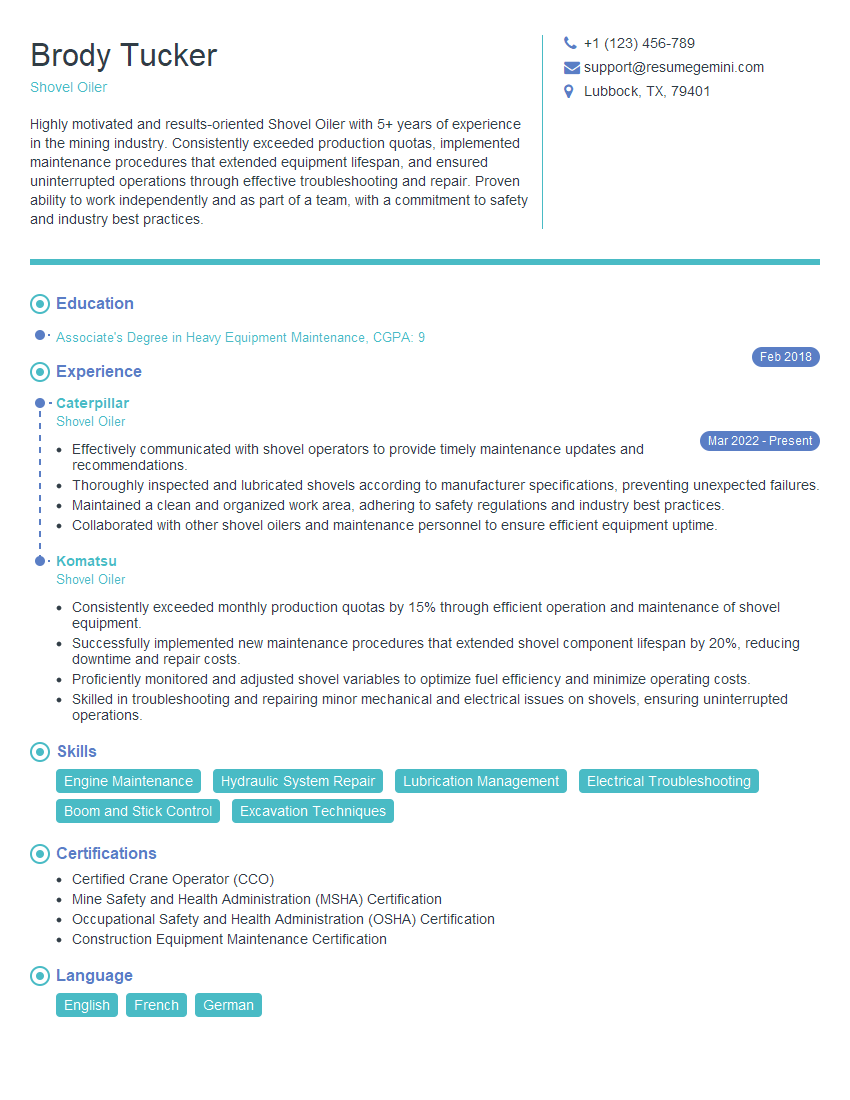

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shovel Oiler

1. Describe the primary responsibilities of a Shovel Oiler?

As a Shovel Oiler, my primary responsibilities would include:

- Lubricating and maintaining shovels and other equipment to ensure smooth operation

- Inspecting and monitoring equipment for any signs of wear or damage

- Replacing worn parts and performing minor repairs as needed

- Assisting in shovel operation and ensuring safe working conditions

2. Can you explain the importance of proper lubrication in shovel operations?

Preventive Maintenance

- Extends equipment lifespan by reducing wear and tear

- Prevents breakdowns and costly repairs

Operational Efficiency

- Reduces friction and allows for smoother operation

- Improves fuel efficiency and reduces emissions

Safety

- Lubricated parts move freely, reducing the risk of accidents

- Reduces heat generation, preventing fires

3. What types of lubricants are commonly used in shovel maintenance?

- Engine oils: Protect and lubricate engine components

- Hydraulic oils: Transmit power and lubricate hydraulic systems

- Gear oils: Lubricate and protect gears and bearings

- Greases: Provide long-term lubrication in high-friction areas

4. Describe the steps involved in lubricating a shovel’s swing gearbox?

- Stop the shovel and allow it to cool

- Locate and clean the gearbox’s lubrication points

- Apply the appropriate lubricant using a grease gun or oil can

- Wipe away excess lubricant and check for leaks

5. What are some common signs of wear or damage in a shovel’s hoisting mechanism?

- Excessive noise or vibration

- Difficulty hoisting or lowering the shovel

- Loose or broken hoisting cables

- Cracks or deformation in the hoisting mechanism components

6. How would you go about replacing a worn bearing in a shovel’s swing mechanism?

- Disassemble the swing mechanism to access the bearing

- Use a bearing puller to remove the worn bearing

- Clean the bearing housing and apply a new bearing

- Reassemble the swing mechanism and check for proper operation

7. What are the safety precautions that should be taken when working on a shovel?

- Wear appropriate PPE, including hard hat, gloves, and safety glasses

- Lock out and tag out equipment before performing any maintenance

- Use proper lifting techniques and avoid working under suspended loads

- Be aware of pinch points and other potential hazards

- Follow all company safety protocols and procedures

8. How do you prioritize maintenance tasks when multiple issues arise simultaneously?

- Assess the severity and urgency of each issue

- Prioritize tasks based on potential safety hazards or equipment damage

- Communicate with supervisors to coordinate repairs and allocate resources

- Delegate tasks to ensure timely completion

9. Can you describe your experience with troubleshooting electrical issues on shovels?

- Diagnose electrical faults using multimeters and other testing equipment

- Repair or replace faulty electrical components, such as wires, fuses, and relays

- Troubleshoot and resolve issues with electrical motors and generators

- Interpret electrical schematics and wiring diagrams

10. How do you stay updated on the latest advancements in shovel maintenance techniques?

- Attend industry conferences and training programs

- Read trade publications and technical journals

- Engage in online forums and discussions with other shovel technicians

- Consult with equipment manufacturers and suppliers for technical updates

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shovel Oiler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shovel Oiler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Shovel Oiler is responsible for maintaining and operating a wide range of equipment in a mining or construction environment. Their primary duties involve lubricating and maintaining equipment, monitoring its performance, and performing minor repairs. They also assist with heavy equipment operation and ensure the safe and efficient running of the worksite.

1. Equipment Maintenance and Lubrication

The Shovel Oiler’s primary responsibility is to ensure that all equipment is properly lubricated and maintained. They regularly inspect equipment for signs of wear, damage, or leaks and take appropriate action to prevent breakdowns or malfunctions. They also perform routine maintenance tasks such as changing oil, filters, and fluids, and may also assist with more complex repairs under the supervision of a mechanic.

- Inspect equipment for signs of wear, damage, or leaks

- Lubricate equipment according to manufacturer’s specifications

- Change oil, filters, and fluids

- Perform minor repairs under the supervision of a mechanic

2. Equipment Monitoring and Troubleshooting

The Shovel Oiler monitors the performance of equipment and identifies any potential issues or malfunctions. They use their knowledge of equipment operation to troubleshoot and resolve minor problems, and report major issues to a supervisor or mechanic. They also keep records of equipment maintenance and repairs, which is crucial for maintaining a safe and efficient worksite.

- Monitor equipment performance

- Identify potential issues or malfunctions

- Troubleshoot and resolve minor problems

- Report major issues to a supervisor or mechanic

- Maintain records of equipment maintenance and repairs

3. Heavy Equipment Operation

In some cases, Shovel Oilers may also assist with the operation of heavy equipment such as shovels or excavators. They typically work under the supervision of an experienced operator and may be responsible for tasks such as loading and unloading materials, moving equipment, or performing basic excavation work. This requires a good understanding of equipment operation and safety procedures.

- Assist with the operation of heavy equipment

- Load and unload materials

- Move equipment

- Perform basic excavation work

4. Worksite Safety and Compliance

Shovel Oilers are responsible for maintaining a safe and compliant worksite. They adhere to all safety regulations and procedures, and ensure that equipment is operated in a safe manner. They may also assist with training new employees on safety practices and procedures, and report any unsafe work practices or conditions to a supervisor.

- Adhere to all safety regulations and procedures

- Ensure that equipment is operated in a safe manner

- Assist with training new employees on safety practices and procedures

- Report any unsafe work practices or conditions to a supervisor

Interview Tips

Preparing thoroughly for a Shovel Oiler interview can significantly increase your chances of success. Here are some tips to help you ace the interview and demonstrate your skills and qualifications:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific Shovel Oiler position. This will give you a good understanding of the company’s culture, values, and the key responsibilities of the role. You can find information on the company website, LinkedIn, and other online sources.

- Visit the company website and LinkedIn page

- Read industry news and articles

- Talk to people in your network who may have worked for the company or in a similar role

2. Highlight Your Skills and Experience

During the interview, be sure to highlight your relevant skills and experience that align with the job requirements. Emphasize your knowledge of equipment maintenance, troubleshooting, and safety procedures. If you have experience operating heavy equipment, be sure to mention that as well. Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Quantify your accomplishments using specific numbers and metrics

- Use the STAR method (Situation, Task, Action, Result) to describe your experiences

- Be prepared to discuss your knowledge of equipment maintenance, troubleshooting, and safety procedures

3. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare a few questions that demonstrate your enthusiasm and knowledge of the industry. Some good questions to ask include: “What are the biggest challenges facing the company in the mining/construction industry?” or “What are the opportunities for career growth within the organization?”

- Prepare questions that demonstrate your enthusiasm and knowledge of the industry

- Ask about the company’s culture and values

- Inquire about opportunities for professional development and advancement

4. Dress Professionally and Arrive on Time

First impressions matter, so make sure to dress professionally for the interview. Arrive on time to show that you are respectful of the interviewer’s time. A positive attitude and a willingness to learn will also go a long way in making a good impression.

- Dress professionally and arrive on time for the interview

- Maintain a positive attitude and be enthusiastic about the opportunity

- Be prepared to answer questions about your experience and qualifications

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Shovel Oiler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!