Are you gearing up for an interview for a Shrink Pit Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Shrink Pit Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

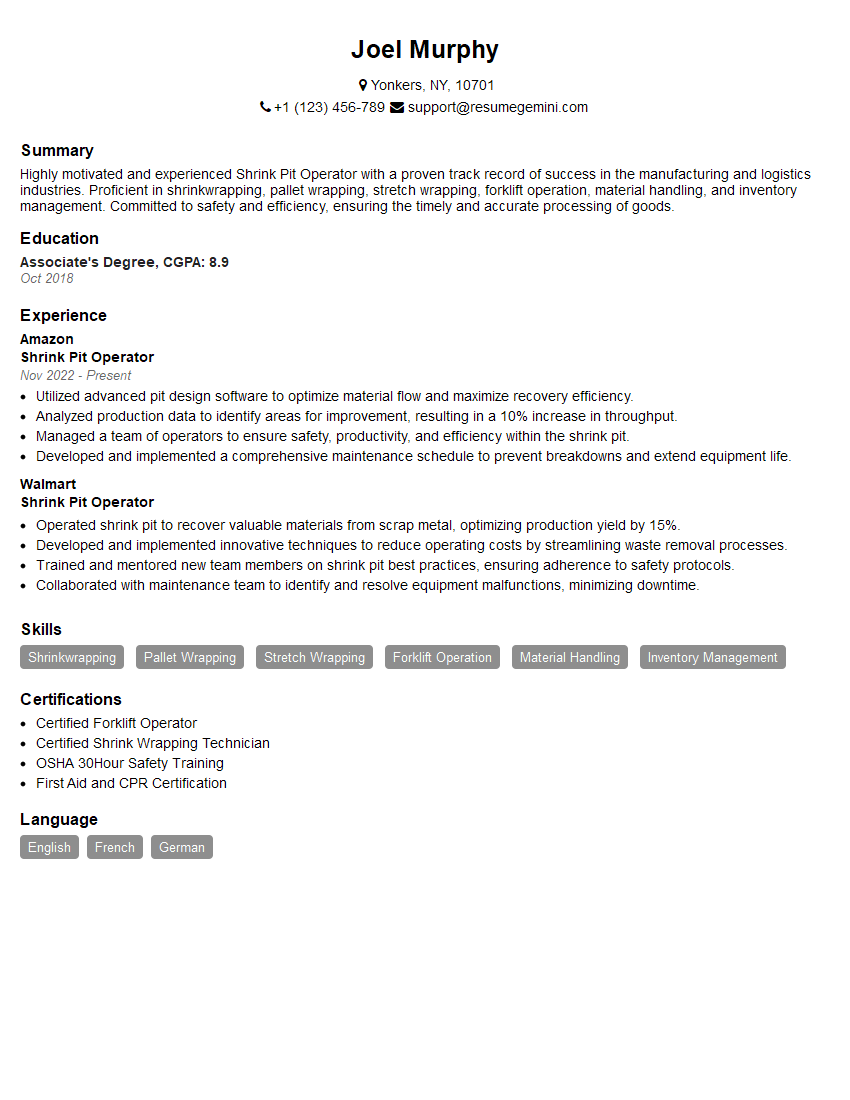

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shrink Pit Operator

1. Describe the key responsibilities of a Shrink Pit Operator?

As a Shrink Pit Operator, my primary responsibilities would include:

- Loading and unloading aluminum scrap into and out of the shrink pit furnace

- Monitoring the furnace temperature and adjusting it as necessary

- Melting and shrinking aluminum scrap to reduce its volume

- Removing dross and other impurities from the molten aluminum

- Casting the molten aluminum into ingots

- Maintaining a clean and safe work area

2. What safety measures should be followed when operating a shrink pit furnace?

Protective Gear:

- Wear appropriate personal protective equipment (PPE), including heat-resistant gloves, apron, and safety glasses

Furnace Operation:

- Ensure the furnace is properly grounded and ventilated

- Never operate the furnace unattended

- Avoid contact with molten aluminum, as it can cause severe burns

Emergency Procedures:

- Be familiar with the emergency shutdown procedures

- Know the location of the nearest fire extinguisher and first aid kit

3. How do you determine the correct temperature for shrinking aluminum scrap?

The correct temperature for shrinking aluminum scrap depends on the type and grade of aluminum being used.

- Generally, aluminum melts at around 660 degrees Celsius (1220 degrees Fahrenheit)

- However, for shrinking, a higher temperature is required to remove impurities and reduce the volume of the scrap

- I would refer to the manufacturer’s specifications or consult with a supervisor to determine the optimal temperature for the specific scrap being processed

4. What are the common challenges faced by Shrink Pit Operators and how do you overcome them?

Some common challenges faced by Shrink Pit Operators include:

- High temperatures: Working near a shrink pit furnace exposes operators to extreme heat. I would wear appropriate PPE and take breaks to cool down as needed.

- Molten metal hazards: Handling molten aluminum poses risks of burns and explosions. I would follow safety procedures, use proper equipment, and maintain a clean work area to minimize these risks.

- Physical demands: The job requires lifting and moving heavy scrap materials. I would use proper lifting techniques and seek assistance when necessary to prevent injuries.

- Dust and fumes: The shrinking process can generate dust and fumes. I would use proper ventilation and wear a respirator to protect my lungs.

5. Describe the process of casting molten aluminum into ingots?

- Prepare the ingot molds by cleaning and lubricating them

- Pour the molten aluminum into the molds

- Allow the aluminum to solidify and cool

- Remove the ingots from the molds and inspect them for defects

6. What are the different types of aluminum scrap that can be processed in a shrink pit furnace?

- Mixed aluminum scrap: A mixture of different types of aluminum, such as cans, extrusions, and castings

- Shredded aluminum scrap: Aluminum that has been shredded into small pieces

- Zorba scrap: Aluminum that has been crushed and baled

- Dross: A byproduct of the aluminum melting process that contains impurities

7. How do you maintain a clean and safe work area around a shrink pit furnace?

- Regularly clean up spills and debris

- Store scrap materials in designated areas

- Dispose of dross and other waste materials properly

- Inspect equipment regularly and make repairs as needed

- Follow all safety procedures and wear appropriate PPE

8. What is the importance of proper ventilation in a shrink pit furnace area?

- Remove harmful fumes and gases generated during the shrinking process

- Prevent the accumulation of dust and other airborne contaminants

- Maintain a safe and healthy work environment for operators

9. How do you calibrate and maintain the temperature control system of a shrink pit furnace?

- Use a calibrated thermocouple or other temperature measuring device

- Compare the readings to a known standard

- Adjust the temperature control system as necessary

- Regularly check and clean the temperature control components

10. Explain the role of dross in the shrink pit furnace process and how it is managed.

Dross is a byproduct of the aluminum melting process that contains impurities and oxides.

- Role: Dross acts as a protective layer on the surface of the molten aluminum, preventing oxidation and contamination.

- Management: Dross is periodically removed from the furnace and disposed of properly. Proper management is crucial to maintain the quality of the molten aluminum and prevent furnace damage.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shrink Pit Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shrink Pit Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Shrink Pit Operator is responsible for overseeing the operations of a shrink pit, a machine used to shrink-wrap and package products. Their key responsibilities include:

1. Equipment Operation

Operating and maintaining shrink pit equipment, including shrink tunnels, conveyors, and sealing systems

- Ensuring proper functioning of equipment and making necessary adjustments

- Troubleshooting and resolving equipment malfunctions

2. Product Packaging

Loading and unloading products onto the shrink pit conveyor system

- Applying shrink wrap to products

- Monitoring the shrink process to ensure proper sealing and packaging

3. Quality Control

Inspecting shrink-wrapped products for quality and compliance with specifications

- Identifying and removing defective or damaged products

- Maintaining records of quality control checks

4. Safety and Maintenance

Adhering to safety protocols and procedures

- Maintaining a clean and organized work area

- Performing routine maintenance and cleaning tasks

Interview Tips

To ace the interview for a Shrink Pit Operator position, it’s crucial to prepare thoroughly and showcase your relevant skills and experience. Here are some tips to help you succeed:

1. Research the Company

Familiarize yourself with the company’s background, products or services, and industry standing. This preparation will demonstrate your interest in the role and the organization.

- Visit the company’s website

- Read industry news and articles

- Check social media platforms for company updates

2. Highlight Relevant Skills

Emphasize the skills and experience that align with the job requirements. Focus on your ability to operate shrink pit equipment, maintain quality standards, and work independently.

- Quantify your accomplishments when possible

- Use specific examples to illustrate your capabilities

- Show that you are familiar with industry best practices

3. Practice Common Interview Questions

Prepare for common interview questions such as “Tell me about yourself” and “Why are you interested in this role?”. Practice your answers to deliver them confidently and concisely.

- Research typical interview questions

- Craft a compelling self-introduction

- Prepare a brief explanation of your interest in the position

4. Be Professional and Enthusiastic

Dress professionally, arrive on time, and maintain a positive and enthusiastic demeanor throughout the interview. Your attitude can make a lasting impression on the interviewer.

- Make eye contact and actively listen

- Be respectful and ask thoughtful questions

- Follow up with a thank-you note after the interview

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Shrink Pit Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!