Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Shrinking Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

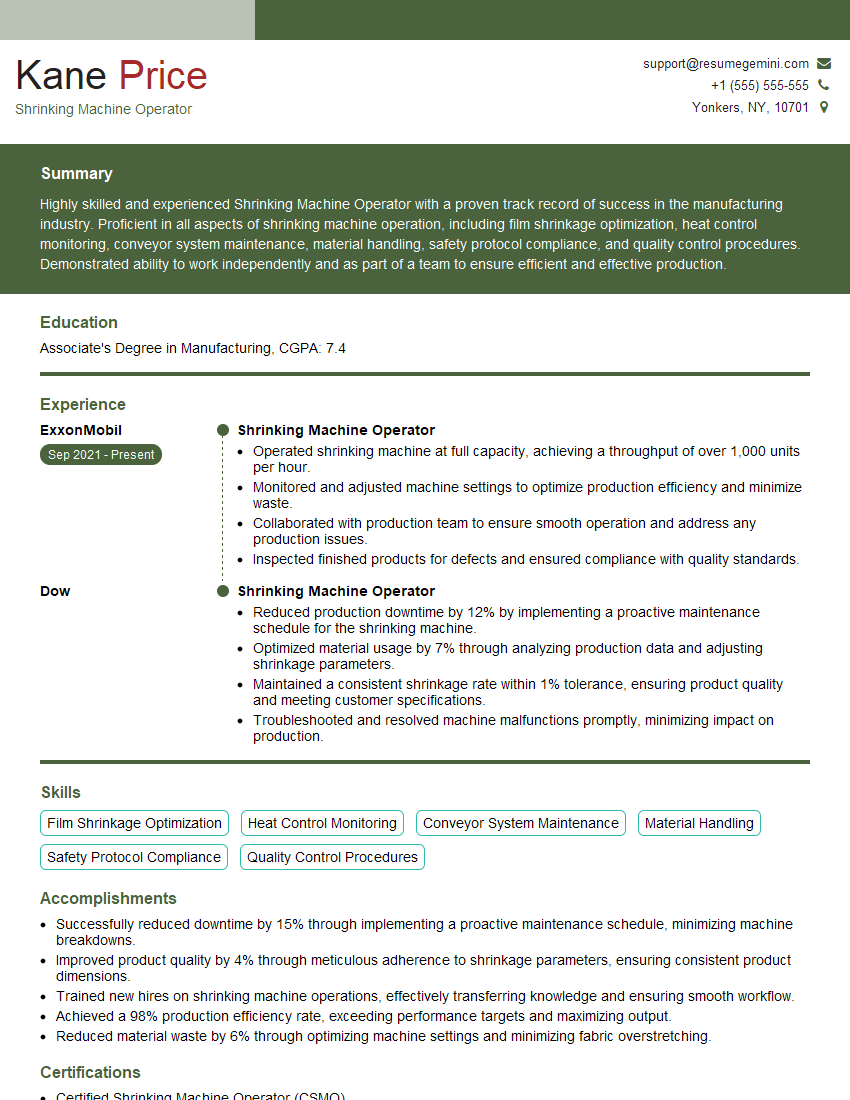

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shrinking Machine Operator

1. How do you ensure that the shrinking machine is operating at its optimal efficiency?

- Regularly clean and maintain the machine to prevent any blockages or malfunctions.

- Inspect the machine’s components, such as the heating element and conveyor belt, for any signs of wear or damage.

- Calibrate the machine according to the manufacturer’s specifications to ensure accurate shrinking.

- Monitor the machine’s performance and make adjustments as needed to maintain optimal efficiency.

2. Describe the process of troubleshooting common issues with a shrinking machine.

Troubleshooting Steps

- Identify the issue by observing the machine’s behavior and error messages.

- Refer to the machine’s manual or consult with a technician for guidance.

- Inspect the machine’s components for any visible damage or blockages.

- Check the machine’s settings and make adjustments as needed.

- Clean and maintain the machine to resolve any performance issues.

Common Issues

- Uneven shrinking or wrinkles: Check the temperature settings and conveyor speed.

- Machine overheating: Inspect the heating element and cooling system.

- Material jamming: Clear any obstructions from the conveyor belt and feed mechanism.

- Electrical faults: Check the power supply and wiring connections.

3. What are the safety protocols you follow when operating a shrinking machine?

- Wear appropriate personal protective equipment (PPE), such as heat-resistant gloves and safety glasses.

- Ensure the machine is properly grounded and all electrical connections are secure.

- Never operate the machine with any guards or covers removed.

- Keep the work area clean and free of tripping hazards.

- Follow the manufacturer’s instructions for safe operation and maintenance.

4. Explain the different types of materials that can be shrunk using a shrinking machine.

- Polyolefin films (e.g., polyethylene, polypropylene)

- PVC films

- PET films

- Some types of fabrics and textiles

5. How do you ensure that the shrunk product meets the required specifications?

- Use precise temperature and conveyor speed settings based on the material and desired shrink ratio.

- Inspect the shrunk product against the specifications, checking dimensions, shape, and any other relevant criteria.

- Make any necessary adjustments to the machine settings or process to achieve the desired results.

- Maintain accurate records of settings and measurements for quality control purposes.

6. Describe the types of maintenance tasks you perform on a shrinking machine.

- Regular cleaning to remove dirt, dust, and debris.

- Lubrication of moving parts to ensure smooth operation.

- Inspection of electrical components, wiring, and connections.

- Replacement of worn or damaged parts as needed.

- Calibration and adjustment of machine settings to maintain accuracy.

7. How do you handle different types of shrink film packaging?

- Identify the type of shrink film (e.g., polyethylene, PVC, PET) and its properties.

- Select the appropriate temperature and conveyor speed settings for the specific film.

- Load the film roll onto the machine and adjust the tension to ensure proper feeding.

- Monitor the shrinking process and make any necessary adjustments to achieve the desired results.

8. How do you troubleshoot and resolve common problems with shrink film packaging?

- Film tearing or breaking: Check the film tension, temperature settings, and conveyor speed.

- Wrinkles or bubbles: Adjust the temperature or conveyor speed to reduce excessive shrinking.

- Film not adhering to the product: Check the film type, surface condition of the product, and temperature settings.

- Product damage during shrinking: Use proper packaging techniques and adjust the heat and speed settings.

9. What is your approach to ensuring the safety of personnel and equipment when operating a shrinking machine?

- Follow proper operating procedures and safety protocols.

- Wear appropriate personal protective equipment (e.g., gloves, safety glasses).

- Inspect the machine regularly for any potential hazards.

- Maintain a clean and organized work area.

- Report any safety concerns or incidents promptly.

10. How do you stay updated with the latest advancements in shrinking machine technology and techniques?

- Attend industry conferences and workshops.

- Read trade publications and technical articles.

- Consult with equipment manufacturers and suppliers.

- Participate in online forums and discussion groups.

- Seek opportunities for professional development and training.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shrinking Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shrinking Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Shrinking Machine Operators are responsible for operating and maintaining shrinking machines used in various industries, including packaging, textile, and manufacturing. Their key responsibilities include:

1. Machine Operation

• Operating shrinking machines to shrink materials such as plastic films, fabrics, and labels.

- Setting up and adjusting machine parameters based on material properties and desired shrinkage.

- Monitoring machine operation and making necessary adjustments to ensure proper functioning.

2. Quality Control

• Ensuring the quality of shrunk materials meets specified standards.

- Inspecting shrunk materials for defects, such as wrinkles, distortions, and uneven shrinkage.

- Conducting tests and measurements to verify compliance with quality requirements.

3. Maintenance and Troubleshooting

• Performing routine maintenance and troubleshooting on shrinking machines.

- Cleaning and lubricating machine components.

- Identifying and repairing minor malfunctions.

- Coordinating with maintenance technicians for major repairs or upgrades.

4. Safety Compliance

• Adhering to safety regulations and protocols when operating shrinking machines.

- Following proper handling procedures for hazardous materials, such as solvents and heat.

- Maintaining a clean and organized work area to prevent accidents.

Interview Tips

To ace your interview for a Shrinking Machine Operator position, consider the following tips and examples:

1. Research the Company and Role

• Research the company’s background, industry, and specific operations to demonstrate your interest and preparedness.

- Example: “I understand that XYZ Corp. is a leading manufacturer of packaging materials. I am particularly interested in your innovative approach to shrink wrapping.

2. Highlight Relevant Skills and Experience

• Emphasize your proficiency in operating shrinking machines, maintaining equipment, and ensuring quality.

- Example: “In my previous role, I was responsible for operating multiple shrinking machines and consistently met or exceeded production targets while maintaining high-quality standards.

3. Demonstrate Safety Awareness

• Showcase your understanding of safety regulations and your commitment to adhering to them.

- Example: “I am fully aware of the safety protocols for handling solvents and operating shrinking machines. I have a proven track record of maintaining a safe work environment.

4. Prepare Questions

• Prepare thoughtful questions to ask the interviewer, demonstrating your engagement and interest in the role.

- Example: “Can you provide more insights into the company’s quality control processes for shrunk materials?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Shrinking Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!