Feeling lost in a sea of interview questions? Landed that dream interview for Shut Off Worker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Shut Off Worker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

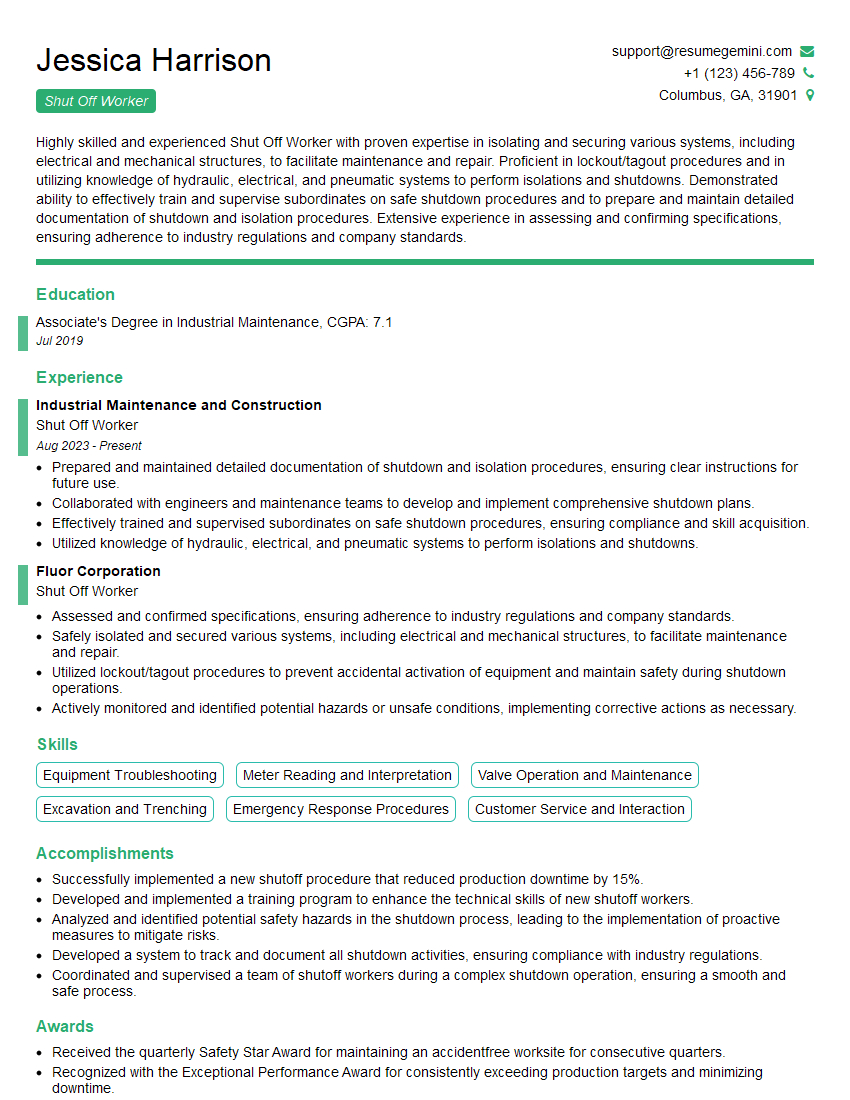

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shut Off Worker

1. Explain the different types of shut off valves and their applications?

There are various types of shut off valves, each designed for specific applications:

- Gate valves: Used for on/off applications, providing a straight-through flow path with minimal pressure drop.

- Globe valves: Similar to gate valves, but with a more tortuous flow path for throttling or flow control.

- Ball valves: Quarter-turn valves with a ball-shaped closure element, offering quick shutoff and low pressure drop.

- Butterfly valves: Similar to ball valves, but with a butterfly-shaped closure element, suitable for large-diameter piping systems.

- Plug valves: Cone-shaped closure elements that seal against a tapered seat, ideal for abrasive or corrosive fluids.

2. Describe the safety precautions to be taken while operating shut off valves under pressure?

Personal Protective Equipment (PPE)

- Wear appropriate PPE, including gloves, safety glasses, and ear protection.

- Ensure good ventilation to prevent breathing in any released fluids.

Valve Operation

- Slowly and gradually open or close valves to avoid sudden pressure changes.

- Use a barring tool for higher-pressure valves to prevent hand injuries.

- Be aware of the flow direction and potential hazards of released fluids.

Emergency Procedures

- Know the location of emergency shutoff valves and operating procedures.

- Stay clear of leaking valves and report any abnormalities promptly.

3. Discuss the maintenance procedures for different types of shut off valves?

Maintenance procedures for shut off valves vary depending on the type and application:

- Visual inspection: Regularly check for leaks, corrosion, or damage.

- Cleaning: Clean valves periodically to remove debris or build-up.

- Lubrication: Lubricate moving parts to ensure smooth operation and prevent wear.

- Packing adjustment: Adjust packing to maintain a proper seal and prevent leaks.

- Seat repair: Replace or repair damaged valve seats to ensure a tight seal.

4. What are the potential causes of shut off valve failures and how can they be prevented?

Shut off valve failures can be caused by various factors:

- Corrosion: Aggressive fluids or environments can corrode valve components, leading to leaks or failure.

- Wear and tear: Excessive use or improper operation can cause wear and tear, affecting valve performance.

- Incorrect installation: Improper installation can introduce leaks or reduce valve efficiency.

- Maintenance neglect: Lack of regular maintenance can lead to premature failure or reduced valve lifespan.

Preventive measures include:

- Selecting corrosion-resistant materials or using protective coatings.

- Proper installation and operating procedures.

- Regular maintenance and inspections to identify and address potential issues.

5. Explain how to troubleshoot and repair a leaking shut off valve?

Troubleshooting and repairing a leaking shut off valve involves the following steps:

- Identify the source of the leak: Check the packing gland, valve seat, or other potential leak points.

- Tighten packing: If the leak is from the packing gland, tighten the gland bolts to compress the packing.

- Replace seat: If the leak is from the valve seat, replace the seat with a new one.

- Repair or replace valve: If the leak persists or the valve is damaged beyond repair, replace the entire valve.

6. What are the different materials used in the construction of shut off valves and their advantages and disadvantages?

Shut off valves are made from various materials, each with its pros and cons:

- Brass: Durable, corrosion-resistant, and suitable for a wide range of applications.

- Bronze: Stronger than brass, suitable for high-pressure or high-temperature applications.

- Stainless steel: Highly corrosion-resistant, often used in food processing or sanitary applications.

- Iron: Cost-effective and suitable for general-purpose applications, but prone to corrosion.

- Plastic: Lightweight, corrosion-resistant, but may have lower pressure ratings.

7. Discuss the importance of proper sizing and selection of shut off valves for a given application?

Proper sizing and selection of shut off valves are crucial for:

- System performance: Ensuring adequate flow rates and pressure control.

- Safety: Preventing over-pressurization or under-sizing.

- System efficiency: Minimizing energy loss due to pressure drop.

- Reliability: Selecting valves that can withstand the operating conditions and provide long-term performance.

8. Explain the differences between manual, automatic, and motorized shut off valves and their applications?

Shut off valves can be operated in various ways:

- Manual: Operated by hand using a lever or wheel.

- Automatic: Activated by a sensor or control system to open or close in response to specific conditions.

- Motorized: Operated by an electric motor, providing remote control or automation.

Applications:

- Manual: Suitable for local control, isolation, or emergency shutoff.

- Automatic: Used in safety or control systems, such as fire suppression or process control.

- Motorized: Ideal for remote control, automation, or high-torque applications.

9. What are the codes and standards that govern the installation and maintenance of shut off valves?

Shut off valves must be installed and maintained according to relevant codes and standards, including:

- ASME B16 Series: Covers pipe fittings, flanges, and valves.

- ANSI/ASME B31 Series: Provides piping codes for various industries.

- NFPA 70 (National Electrical Code): Includes requirements for electrical installations involving valves.

- Company-specific standards and procedures: May provide additional guidelines or specifications.

10. Describe the environmental considerations when selecting and operating shut off valves?

Environmental considerations include:

- Material compatibility: Selecting materials that are compatible with the fluid and environment to prevent corrosion or contamination.

- Leak prevention: Ensuring valves are leak-proof to minimize fluid loss and emissions.

- Energy efficiency: Choosing valves with low-pressure drop to reduce energy consumption.

- Responsible disposal: Proper disposal of used valves to prevent environmental contamination.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shut Off Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shut Off Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Shut Off Worker is responsible for the safe and efficient shutdown of equipment, machinery, and systems. They ensure that proper procedures are followed to prevent damage to equipment, harm to personnel, and environmental contamination.

1. Equipment Shutdown

Shut Down Workers are responsible for following established procedures to shut down equipment and systems. This includes:

- Identifying and isolating equipment and systems to be shut down.

- Closing valves, switches, and controls to stop the flow of energy or materials.

- Draining or flushing systems to remove hazardous materials.

- Monitoring equipment and systems during shutdown to ensure that they are responding as expected.

2. Safety and Compliance

Shut Down Workers are responsible for ensuring that all safety procedures are followed during shutdown. This includes:

- Wearing proper personal protective equipment (PPE).

- Using safe work practices.

- Following established lockout/tagout procedures.

- Reporting any unsafe conditions or practices.

3. Equipment Maintenance

Shut Down Workers may also be responsible for performing basic maintenance on equipment during shutdown. This includes:

- Cleaning and inspecting equipment.

- Making minor repairs.

- Lubricating moving parts.

- Replacing filters and other расходникиs.

4. Documentation

Shut Down Workers are responsible for documenting the shutdown process. This includes:

- Recording the time and date of shutdown.

- Noting any unusual conditions or observations.

- Providing a written report of the shutdown to the appropriate personnel.

Interview Preparation Tips

There are a number of things you can do to prepare for an interview for a Shut Off Worker position.

1. Research the Company and Position

Take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website.

- Read the job description carefully.

- Talk to people in your network who may know about the company or the position.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked. Take the time to practice your answers to these questions so that you can deliver them confidently and clearly during the interview.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- Describe a time when you had to deal with a difficult customer or situation.

3. Be Prepared to Talk About Your Experience

The interviewer will likely ask you about your experience in the field. Be prepared to talk about your experience in detail, including your skills and accomplishments.

- Highlight your experience in shutting down equipment and systems.

- Describe your experience in following safety procedures.

- Discuss your experience in performing basic maintenance on equipment.

4. Be Enthusiastic and Professional

Make sure to show your enthusiasm for the position and the company during the interview. Be professional and respectful, and dress appropriately.

- Make eye contact with the interviewer.

- Speak clearly and confidently.

- Be polite and respectful.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Shut Off Worker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Shut Off Worker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.