Are you gearing up for an interview for a Shuttle Veneering Supervisor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Shuttle Veneering Supervisor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

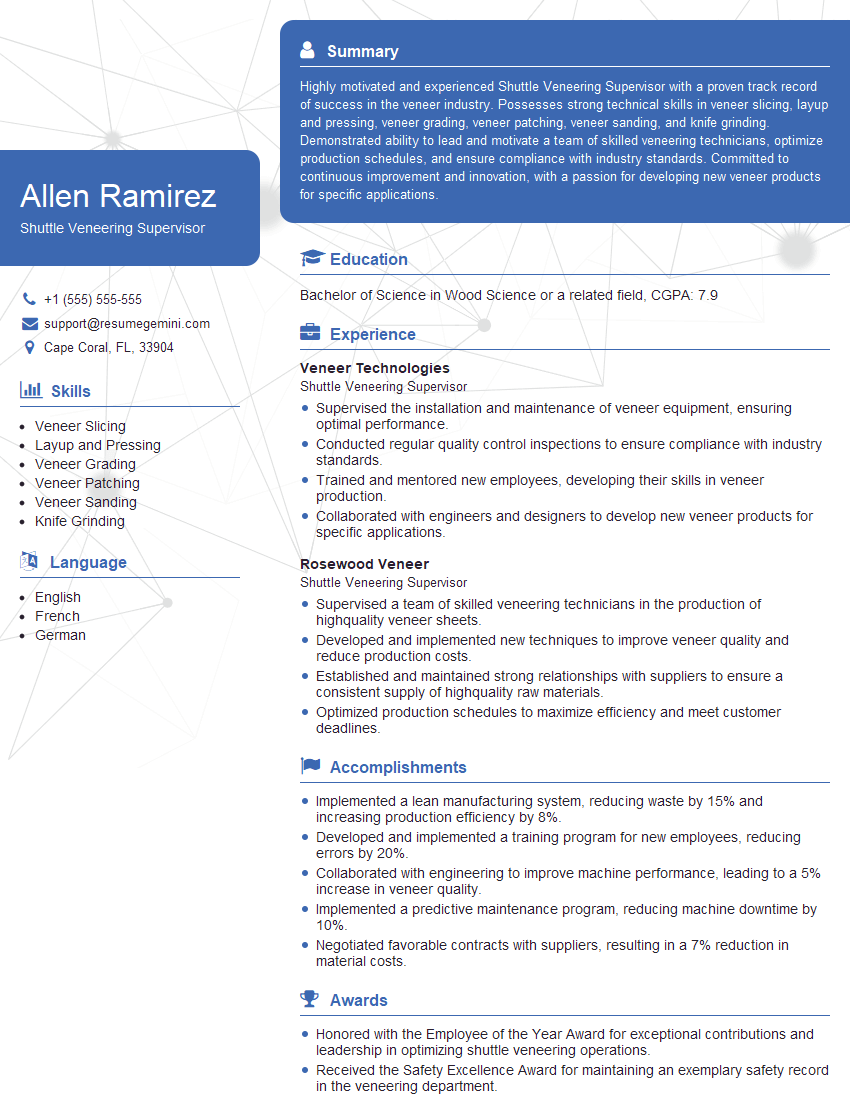

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shuttle Veneering Supervisor

1. Describe the key technical challenges you faced in a shuttle veneering operation and how you overcame them?

- Variation in veneer thickness and inconsistency in production

- Managing different types of veneers, including exotic and rare species

- Challenges in ensuring the quality of spliced joints with varying grain patterns

- Optimizing adhesive application and ensuring proper curing

- Troubleshooting and resolving issues related to press operation and temperature control

2. How do you optimize the shuttle veneering process to maximize yield and minimize waste?

Cost-effective veneer utilization

- Implementing yield optimization techniques to minimize veneer trimming loss

- Developing cutting plans to maximize utilization and reduce waste

- Exploring alternative veneer sources and species to lower costs

Process efficiency

- Automating or semi-automating tasks to increase throughput

- Streamlining the production process to reduce lead times

- Implementing proper maintenance and calibration schedules to minimize downtime

3. What specific quality control measures are used to ensure the quality and consistency of shuttle veneered products?

- Visual inspection of incoming veneers for defects and damages

- Thickness and moisture content testing to meet industry standards

- Adhesion testing to ensure proper bonding strength

- Surface finishing evaluation to check for smoothness and absence of imperfections

- Dimensional accuracy and flatness measurements

4. What are the critical safety precautions and procedures that must be followed in a shuttle veneering operation?

- Proper machine guarding and maintenance

- Use of personal protective equipment, including gloves, safety glasses, and ear protection

- Safe handling and storage of chemicals and adhesives

- Training and supervision of operators on safety measures

- Emergency procedures and drills

5. What techniques do you use to train and develop your team of shuttle veneer machine operators?

- On-the-job training under experienced operators

- Demonstration and hands-on practice

- Theoretical knowledge sessions

- Cross-training on different machines and processes

- Performance evaluation and feedback

6. Describe the maintenance and troubleshooting procedures you implement to ensure the smooth operation of shuttle veneering machines?

- Regular scheduled maintenance and inspections

- Predictive maintenance using vibration analysis and temperature monitoring

- Troubleshooting common issues, such as hydraulic leaks, temperature fluctuations, and electrical faults

- Collaboration with maintenance technicians to resolve complex problems

- Documentation of maintenance activities and performance

7. What are the key performance indicators (KPIs) you use to measure the effectiveness of your shuttle veneering operation?

- Veneer yield percentage

- Production volume and efficiency

- Quality control pass rate

- Machine uptime and downtime

- Customer satisfaction and complaint rates

8. Explain how you handle customer inquiries and complaints about shuttle veneered products?

- Promptly acknowledging and responding to inquiries and complaints

- Thoroughly investigating the issue and determining the root cause

- Collaborating with production and quality control teams to find solutions

- Providing clear explanations and updates to customers

- Implementing corrective actions to prevent recurrence of issues

9. Describe how you stay up-to-date on the latest advancements in shuttle veneering technology and industry trends?

- Attending industry conferences and exhibitions

- Reading trade publications and technical journals

- Networking with peers and vendors

- Researching new materials and advancements

- Seeking professional development opportunities

10. How do you manage and motivate your team to achieve the highest levels of performance and quality?

- Setting clear goals and expectations

- Providing regular feedback and recognition

- Empowering team members and encouraging teamwork

- Creating a positive and supportive work environment

- Offering training and development opportunities

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shuttle Veneering Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shuttle Veneering Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Shuttle Veneering Supervisor is a critical role within the organization, responsible for overseeing the production of high-quality veneered panels. Key job responsibilities include:

1. Production Management

Supervise and manage the shuttle veneering line, ensuring efficient and effective operation.

- Develop and implement production schedules, optimizing line throughput and minimizing downtime.

- Monitor line production, identifying and resolving bottlenecks or production issues promptly.

2. Quality Control

Maintain strict quality standards for veneered panels, adhering to established specifications.

- Inspect raw materials, ensuring they meet specifications before production begins.

- Conduct regular in-process inspections, identifying and correcting any defects.

- Perform final product inspections, ensuring panels meet customer requirements.

3. Team Supervision

Lead and motivate a team of production operators, ensuring a high level of performance.

- Provide training and support to team members, enhancing their skills and knowledge.

- Monitor employee performance, providing feedback and coaching to improve productivity.

- Maintain a positive and productive work environment, fostering teamwork and collaboration.

4. Maintenance and Troubleshooting

Perform preventive maintenance on equipment and troubleshoot any technical issues that arise.

- Identify and order necessary replacement parts, ensuring minimal production downtime.

- Collaborate with maintenance personnel to resolve complex technical issues.

- Maintain inventory of spare parts and materials, ensuring smooth production operations.

Interview Tips

To ace your interview for a Shuttle Veneering Supervisor position, here are some tips to help you prepare:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends. This shows you are genuinely interested in the role and have taken the time to learn about the organization.

- Visit the company’s website, social media pages, and industry publications.

- Research industry-specific news and trends to demonstrate your understanding of the market.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful responses that highlight your skills and experience. Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Have specific examples ready to demonstrate your abilities in production management, quality control, team supervision, and maintenance.

- Be prepared to discuss your leadership style and how you motivate and develop your team.

3. Emphasize Your Technical Skills

Highlight your understanding of shuttle veneering technology and your ability to troubleshoot and resolve technical issues. Use specific examples to demonstrate your expertise.

- Explain your experience with different types of veneer presses and adhesive systems.

- Discuss your knowledge of wood species, properties, and veneer matching techniques.

4. Showcase Your Leadership Abilities

Emphasize your leadership skills, including your ability to motivate and inspire your team. Provide examples of how you have successfully managed and developed production teams.

- Describe how you have created a positive and productive work environment.

- Share your strategies for managing employee performance and providing constructive feedback.

5. Be Professional and Enthusiastic

Dress professionally, arrive on time for your interview, and maintain a positive and enthusiastic attitude throughout the process. Demonstrate your interest in the role and the company.

- Be polite and respectful to everyone you meet, including the receptionist and other employees.

- Ask thoughtful questions at the end of the interview to show your engagement and interest.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Shuttle Veneering Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!