Are you gearing up for an interview for a Side Stitching Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Side Stitching Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

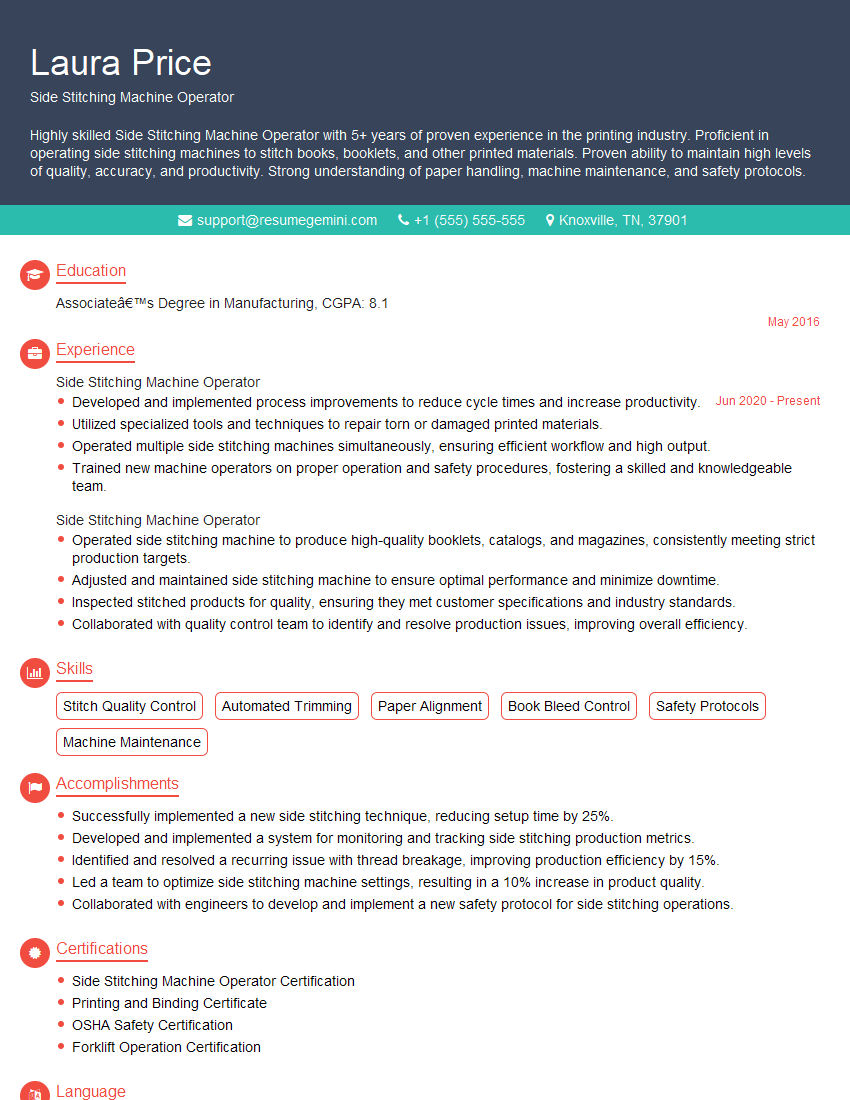

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Side Stitching Machine Operator

1. Describe the process of setting up a side stitching machine for a new job.

The process of setting up a side stitching machine for a new job involves several steps to ensure accurate and efficient stitching:

- Inspect the Machine: Check the machine’s overall condition, ensuring there are no loose parts or signs of damage.

- Prepare the Machine: Select the appropriate stitching heads and thread tension based on the job requirements.

- Position the Guides: Adjust the side guides and back gauge to match the desired stitch margin and paper size.

- Thread the Machine: Insert the thread through the tension disks and needles, ensuring it is securely fastened.

- Set the Stitching Parameters: Program the machine to the specified stitch length, thread tension, and speed.

- Calibrate the Machine: Run a series of test stitches to ensure the machine is functioning correctly.

2. How do you troubleshoot common problems with side stitching machines, such as thread breakage or paper jams?

Identifying Thread Breakage Issues

- Check thread tension settings: Ensure the tension is not too tight or too loose.

- Inspect the thread path: Look for any obstructions or sharp edges that may cause the thread to break.

- Examine the needles: Make sure the needles are sharp and not bent or damaged.

Resolving Paper Jams

- Clear the machine area: Remove any jammed paper or debris from the machine.

- Check the paper guides: Ensure the paper guides are aligned correctly and not obstructing the paper flow.

- Inspect the grippers: Make sure the grippers are clean and functioning properly to prevent paper slipping.

3. What type of maintenance is required for a side stitching machine to ensure optimal performance?

- Regular Cleaning: Remove dust and debris from the machine’s exterior and interior components.

- Lubrication: Apply lubricant to designated points to reduce friction and maintain smooth operation.

- Tension Adjustment: Check and adjust thread tension regularly to prevent thread breakage or puckering.

- Needle Replacement: Replace worn or damaged needles promptly to ensure stitch quality.

- Electrical Inspection: Have a qualified technician inspect the machine’s electrical components for any potential issues.

4. How do you ensure the quality of stitched products meets the required standards?

- Pre-Inspection: Check the paper stock and adjust machine settings accordingly.

- In-Process Monitoring: Regularly inspect the stitching quality and make necessary adjustments.

- Post-Stitching Inspection: Verify the stitch count, alignment, and overall appearance of the finished products.

- Calibration and Maintenance: Keep the machine calibrated and well-maintained to ensure consistent stitch quality.

5. What experience do you have with different types of side stitching machines, such as saddle stitchers or perfect binders?

I have experience with a variety of side stitching machines, including:

- Saddle Stitchers: I have operated saddle stitchers to produce booklets, brochures, and magazines.

- Perfect Binders: I have used perfect binders to create case-bound books with adhesive binding.

- Loop Stitchers: I have utilized loop stitchers for wire-o binding, which produces durable and flexible documents.

6. How do you handle working in a fast-paced production environment where accuracy and efficiency are crucial?

- Time Management: I prioritize tasks effectively and allocate my time wisely to meet deadlines.

- Attention to Detail: I maintain a high level of accuracy by carefully inspecting products and following instructions precisely.

- Problem-Solving: I quickly identify and resolve any issues that arise, minimizing downtime.

- Adaptability: I am flexible and can adjust to changing demands and work on multiple projects simultaneously.

7. Can you describe the safety measures you follow when operating a side stitching machine?

- Machine Inspection: I ensure the machine is in good working order before operating it.

- Proper Attire: I wear appropriate safety gear, such as gloves and safety glasses.

- Guard Usage: I keep all safety guards in place and use them properly.

- Lockout/Tagout: I follow proper procedures for locking out and tagging out the machine before performing maintenance.

8. How do you stay up-to-date with the latest advancements and best practices in side stitching technology?

- Industry Publications: I read industry magazines and articles to stay informed about new techniques and developments.

- Attend Training: I participate in training programs and workshops to enhance my skills.

- Networking: I connect with other professionals in the field to exchange knowledge and learn from their experiences.

9. What are your strengths and weaknesses as a side stitching machine operator?

Strengths:

- Technical Proficiency: I have a deep understanding of side stitching machines and can operate them efficiently.

- Attention to Detail: I am meticulous in my work and ensure high precision in my stitching.

- Problem-Solving: I am quick to identify and resolve any issues that arise during operation.

Weaknesses:

- Limited Experience with Automation: I have primarily worked with manual side stitching machines and have limited experience with automated systems.

- Shift Work: While I am willing to work flexible hours, I may need some time to adjust to working night shifts.

10. Why are you interested in this side stitching machine operator position, and why do you think you are a suitable candidate?

I am eager to join your team as a Side Stitching Machine Operator because I am confident in my abilities to contribute to your production goals. My technical proficiency, attention to detail, and commitment to quality make me an ideal candidate for this role. I am a highly motivated and results-driven individual with a strong work ethic and a passion for delivering exceptional results.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Side Stitching Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Side Stitching Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Side Stitching Machine Operator is responsible for operating a side stitching machine to bind and finish printed materials such as books, magazines, and booklets. The key job responsibilities include:

1. Operating the side stitching machine

This involves setting up the machine, loading the materials, adjusting the settings, and monitoring the stitching process to ensure that the finished products meet quality standards.

2. Preparing and handling materials

This includes preparing the materials for stitching, such as folding and aligning the pages, and handling the materials during and after the stitching process.

3. Inspecting the finished products

This involves checking the finished products for defects, such as misaligned pages or loose stitching, and ensuring that they meet the required specifications.

4. Maintaining the machine

This involves cleaning and lubricating the machine, as well as performing minor repairs and adjustments as needed.

Interview Preparation Tips

Preparing for an interview for a Side Stitching Machine Operator position is essential to increase your chances of success. Here are some tips to help you ace the interview:

1. Research the company and the position

Gather information about the company’s history, products, and services, as well as the specific requirements of the Side Stitching Machine Operator position. This will demonstrate your interest in the position and the company.

2. Practice answering common interview questions

Prepare for questions about your experience, skills, and qualifications. Some common questions include:

- Tell me about your experience operating a side stitching machine.

- What are your strengths and weaknesses as a Side Stitching Machine Operator?

- How do you handle quality control issues?

3. Be prepared to discuss your experience with different types of materials

Side Stitching Machine Operators may work with a variety of materials, such as paper, cardboard, and plastic. Be prepared to discuss your experience with different materials and how you handle the specific challenges associated with each type.

4. Dress professionally and arrive punctually

First impressions matter, so dress professionally and arrive on time for your interview. This will show that you are serious about the position and that you respect the interviewer’s time.

5. Prepare questions to ask the interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Some good questions to ask include:

- What are the company’s goals for this position?

- What is the company culture like?

- What are the opportunities for advancement within the company?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Side Stitching Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.