Feeling lost in a sea of interview questions? Landed that dream interview for Silica Spray Mixer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Silica Spray Mixer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

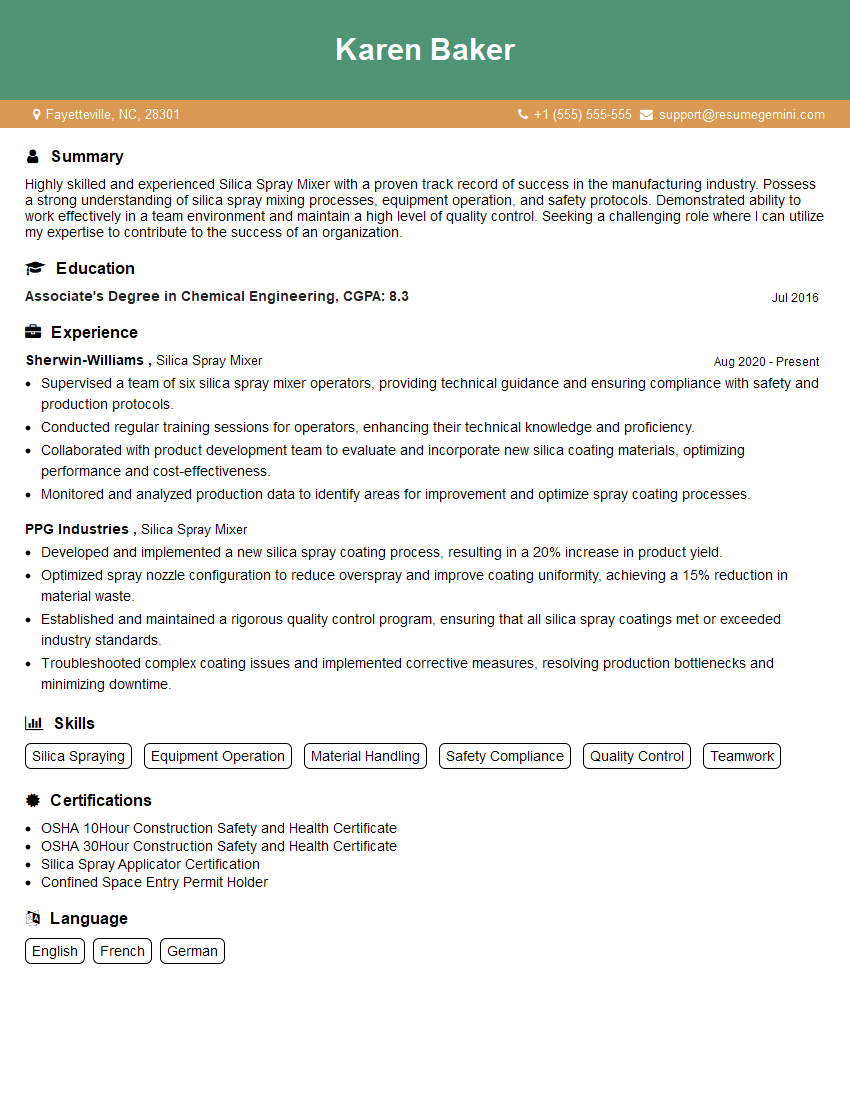

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Silica Spray Mixer

1. Can you tell me about the process of silica spray mixing?

In silica spray mixing, silica sand is mixed with a liquid binder to create a slurry. This slurry is then sprayed onto a surface, where it dries and forms a hard, durable coating. The process is used in a variety of applications, including construction, automotive, and aerospace.

2. What are the different types of silica spray mixers?

- Pneumatic mixers: Use compressed air to atomize the liquid binder and mix it with the silica sand.

- Mechanical mixers: Use mechanical agitation to mix the liquid binder and silica sand.

- Hydraulic mixers: Use hydraulic pressure to mix the liquid binder and silica sand.

3. What are the factors that affect the quality of the silica spray coating?

- The type and quality of the silica sand

- The type and concentration of the liquid binder

- The spray pressure and nozzle size

- The surface preparation and coating thickness

- The curing conditions

4. What are the advantages and disadvantages of using silica spray coatings?

Advantages

- Excellent corrosion resistance

- High strength and durability

- Good thermal insulation properties

- Low maintenance requirements

Disadvantages

- Can be expensive to apply

- Requires specialized equipment and training

- Can be difficult to repair if damaged

5. What are the safety precautions that must be taken when working with silica spray mixtures?

- Wear proper personal protective equipment, including a respirator, gloves, and eye protection.

- Ventilate the work area to prevent the inhalation of silica dust.

- Handle the silica spray mixture with care to avoid spills and splashes.

- Dispose of the silica spray mixture properly according to local regulations.

6. What are the common problems that can occur during silica spray mixing and how can they be resolved?

- Clogging of the spray nozzle: This can be resolved by cleaning the nozzle with a solvent or by increasing the spray pressure.

- Uneven coating thickness: This can be resolved by adjusting the spray distance, nozzle size, or spray pattern.

- Poor adhesion of the coating to the surface: This can be resolved by properly preparing the surface before applying the coating.

- Cracking or peeling of the coating: This can be resolved by using a higher quality silica sand or liquid binder, or by increasing the curing time.

7. What are the latest trends in silica spray mixing technology?

- The development of new and improved silica sand materials

- The development of new and improved liquid binders

- The development of new and improved spray equipment

- The development of new and improved curing techniques

8. What are the future prospects for the silica spray mixing industry?

The silica spray mixing industry is expected to grow in the coming years due to the increasing demand for corrosion-resistant and durable coatings in a variety of applications. The industry is also expected to benefit from the development of new and improved technologies.

9. What is your experience with silica spray mixing?

I have been working with silica spray mixing for the past 5 years. In my previous role, I was responsible for the operation and maintenance of a silica spray mixing plant. I have a deep understanding of the process and the equipment used, and I have a proven track record of producing high-quality silica spray coatings.

10. Why are you interested in working as a Silica Spray Mixer?

I am interested in working as a Silica Spray Mixer because I am passionate about the industry and I am confident that I have the skills and experience to be successful in this role. I am eager to learn more about the process and the equipment used, and I am confident that I can make a valuable contribution to your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Silica Spray Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Silica Spray Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Silica Spray Mixer operates and monitors automated silica-spraying equipment within a foundry to create sand cores and molds used in the production of metal castings. They mix and spray silica sand with a binder to create a slurry, which is then sprayed onto a pattern to form the core or mold.

1. Mixing and Spraying Silica Sand

The primary responsibility of a Silica Spray Mixer is to mix and spray silica sand to create sand cores and molds. This involves:

- Loading silica sand, binder, and other materials into the mixing chamber.

- Adjusting the proportions of the silica sand and binder based on the desired properties of the core or mold.

- Mixing the materials thoroughly to create a uniform slurry.

- Spraying the slurry onto a pattern using a spray gun, ensuring an even and consistent coverage.

2. Monitoring and Maintaining Equipment

Silica Spray Mixers are also responsible for monitoring and maintaining the silica-spraying equipment. This involves:

- Checking the equipment for proper operation and making adjustments as necessary.

- Cleaning and lubricating the equipment regularly to prevent breakdowns and ensure optimal performance.

- Inspecting the equipment for wear and tear and reporting any issues to the supervisor.

3. Quality Control and Safety

Silica Spray Mixers play a crucial role in maintaining the quality of the sand cores and molds produced. They must:

- Adhere to established quality standards and specifications for the mixing and spraying process.

- Inspect the finished cores and molds to ensure they meet the required dimensions, shape, and surface finish.

- Follow safety protocols and wear appropriate protective gear to minimize exposure to silica dust and other hazardous materials.

4. Other Responsibilities

In addition to the primary responsibilities mentioned above, Silica Spray Mixers may also be required to:

- Assist in the maintenance and repair of the foundry.

- Operate forklifts or other material handling equipment to move materials.

- Unload and store materials, such as silica sand and binders.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for a Silica Spray Mixer position:

1. Research the Company and Position

Take the time to research the foundry and the specific Silica Spray Mixer position. This will help you understand the company culture, the role’s responsibilities, and the qualifications they are seeking.

- Review the company’s website, social media pages, and industry publications.

- Read the job description carefully and identify the key skills and experience required.

2. Highlight Your Relevant Skills and Experience

In your resume and interview, be sure to emphasize your skills and experience that are relevant to the Silica Spray Mixer position. This includes:

- Experience in operating and maintaining silica-spraying equipment.

- Knowledge of silica sand mixing and spraying techniques.

- Understanding of quality control procedures for sand cores and molds.

- Safety training and experience in handling hazardous materials.

3. Prepare for Common Interview Questions

Anticipate the common interview questions that you are likely to be asked, such as:

- Tell me about your experience in operating silica-spraying equipment.

- How do you ensure the quality of the sand cores and molds you produce?

- What safety precautions do you take when working with silica dust?

- How do you handle equipment breakdowns and malfunctions?

4. Ask Informed Questions

Asking informed questions at the end of the interview shows that you are engaged and interested in the position. It also gives you the opportunity to clarify any details about the role or the company. For example, you could ask:

- What is the typical production schedule for a Silica Spray Mixer in your foundry?

- What opportunities are there for professional development and advancement within the company?

- How does the company ensure the safety of its employees who work with silica dust?

Next Step:

Now that you’re armed with the knowledge of Silica Spray Mixer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Silica Spray Mixer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini