Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Silicator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

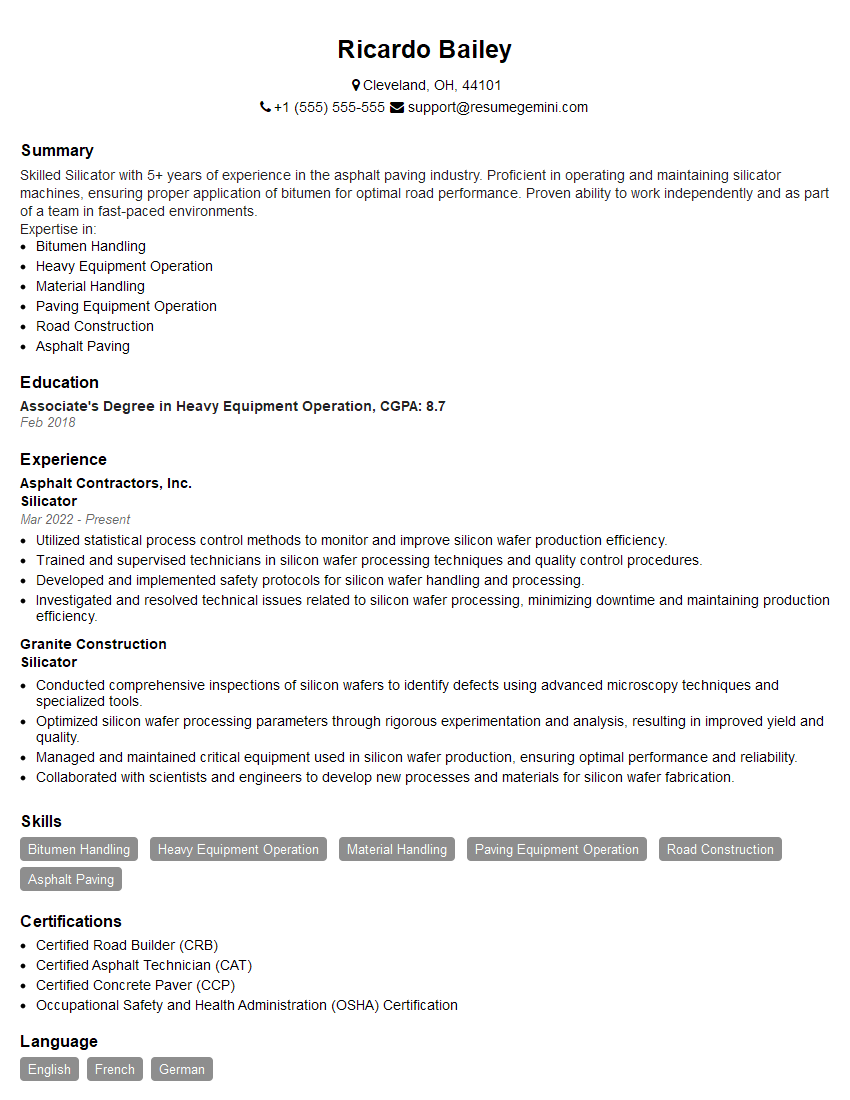

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Silicator

1. What techniques do you use to identify and eliminate potential failure points in silicone coating applications?

- Failure Mode and Effects Analysis (FMEA)

- Risk Assessment and Mitigation Planning

- Design for Reliability (DfR) principles

- Root Cause Analysis (RCA) to investigate and address failures

- Statistical Process Control (SPC) to monitor and maintain process stability

2. Describe the different types of silicone coatings, their properties, and their applications.

Adhesive coatings

- Excellent adhesion to various substrates

- Used for sealing, bonding, and protecting components

Anti-fouling coatings

- Prevent marine growth and biofouling on surfaces

- Applied to underwater structures, boat hulls, and other marine equipment

Electrical insulation coatings

- High dielectric strength and low electrical conductivity

- Used to protect electrical components from short circuits and arcing

3. What are the critical factors to consider when selecting a silicone coating for a specific application?

- Substrates being coated

- Environmental conditions (temperature, humidity, UV exposure)

- Desired coating properties (adhesion, flexibility, durability)

- Application method (spraying, dipping, brushing)

- Cost and availability

4. Describe the process of applying silicone coatings and the key quality control measures involved.

- Surface preparation (cleaning, abrading)

- Coating application (spray, dip, brush)

- Curing (heat or room temperature)

- Film thickness and uniformity

- Adhesion testing

- Electrical testing (for electrical insulation coatings)

Quality control measures

5. What are the common challenges encountered in silicone coating applications and how do you address them?

- Poor adhesion: Ensure proper surface preparation and select the appropriate coating for the substrate.

- Cracking and peeling: Optimize coating thickness, apply multiple thin coats, and cure properly.

- Discoloration: Use UV-stable coatings or add pigments to enhance color retention.

- Contamination: Implement clean application practices and use high-quality materials.

6. Describe how you maintain and calibrate coating application equipment to ensure accurate and consistent results.

- Regular cleaning and maintenance

- Calibrating spray guns and dipping tanks

- Monitoring and controlling process parameters (temperature, viscosity, flow rate)

- Using reference standards and performing test runs

7. How do you ensure the safety and environmental compliance of silicone coating operations?

- Proper ventilation and respiratory protection

- Safe handling and storage of materials

- Waste disposal according to regulations

- Compliance with industry standards and environmental regulations

8. What are the emerging trends in silicone coating technology?

- Self-healing coatings: Ability to repair minor damage without external intervention.

- Antimicrobial coatings: Coatings infused with antimicrobial agents to inhibit microbial growth.

- Smart coatings: Coatings with sensors or responsive materials for self-monitoring and adaptability.

- Sustainable coatings: Coatings made from bio-based or renewable resources with lower environmental impact.

9. How do you stay updated on the latest developments and advancements in the field of silicone coatings?

- Attending industry conferences and webinars

- Reading technical journals and articles

- Networking with industry professionals

- Researching and exploring new products and technologies

10. Describe your experience with coating quality management systems, such as ISO 9001.

- Understanding of quality management principles

- Experience in developing and implementing quality control procedures

- Ability to monitor and improve coating processes

- Familiarity with ISO 9001 certification and auditing

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Silicator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Silicator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As an experienced Silicator, your role will involve performing various essential tasks, ensuring that silicon-based products are created according to specifications. You will play a vital role in the production process of silicators, paints, and other silicon-based products.

1. Raw Materials Preparation

Begin by ensuring that all raw materials meet the required specifications. This includes checking their quality, quantity, and compatibility with the production process.

- Inspect incoming raw materials (e.g., silicon, fillers, pigments) to verify their quality and compliance with specifications.

- Weigh and measure raw materials accurately to ensure precise formulations.

2. Mixing and Processing

Skilfully mix and process raw materials to create silicon-based products. Monitor the mixing process closely to achieve the desired consistency and properties.

- Operate mixing equipment to combine raw materials evenly and thoroughly.

- Adjust mixing parameters (e.g., speed, temperature, duration) to optimize the product’s properties.

3. Quality Control and Testing

Meticulously inspect and test silicators and other silicon-based products to ensure they meet quality standards. Identify and rectify any defects or inconsistencies.

- Perform quality control tests (e.g., viscosity, adhesion, curing time) to verify product specifications.

- Analyze test results and identify areas for improvement in the production process.

4. Production Optimization

Continuously seek ways to improve the production process. Suggest and implement innovative techniques to enhance efficiency, reduce costs, and minimize waste.

- Monitor production processes and identify bottlenecks or inefficiencies.

- Recommend and implement process modifications to streamline operations and increase productivity.

Interview Tips for Silicator

To ace your silicor interview, we recommend you follow these tips and prepare thoroughly. Your preparation will boost your confidence and help you make a great impression on the hiring manager.

1. Research the Company and Position

Take the time to thoroughly research the company you’re applying to and the silicor position itself. Understand the company’s culture, values, and recent developments. This will help you tailor your resume and cover letter and demonstrate your genuine interest in the opportunity.

- Visit the company’s website to learn about their mission, products, and services.

- Check industry news and articles to stay updated on the latest trends and advancements in the field.

2. Highlight Your Skills and Experience

Carefully review the job description and identify the key skills and experience required for the silicor position. Highlight these in your resume and cover letter, providing specific examples and quantifying your accomplishments whenever possible.

- Emphasize your expertise in silicor production, mixing and processing techniques, and quality control procedures.

- Mention any industry-specific certifications or training programs you have completed to demonstrate your commitment to professional development.

3. Practice Common Interview Questions

Prepare for common interview questions by researching online resources and practicing your answers. This will help you feel more confident and articulate during the interview.

- Prepare answers to questions about your technical skills, experience with different types of silicators, and your problem-solving abilities.

- Consider questions about your teamwork skills, attention to detail, and ability to work in a fast-paced environment.

4. Dress Professionally and Arrive on Time

First impressions matter, so make sure you dress professionally for your interview. Arrive on time to show respect for the interviewer’s time and demonstrate your punctuality.

- Choose formal or business casual attire that is clean and pressed.

- Plan your route to the interview location in advance and allow extra time for unexpected delays.

5. Follow Up After the Interview

After the interview, send a thank-you note to the interviewer within 24 hours. This is an opportunity to reiterate your interest in the position and thank them for their time. You can also use this opportunity to clarify any points discussed during the interview or provide additional information if necessary.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Silicator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!