Are you gearing up for an interview for a Silk Screen Etcher position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Silk Screen Etcher and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

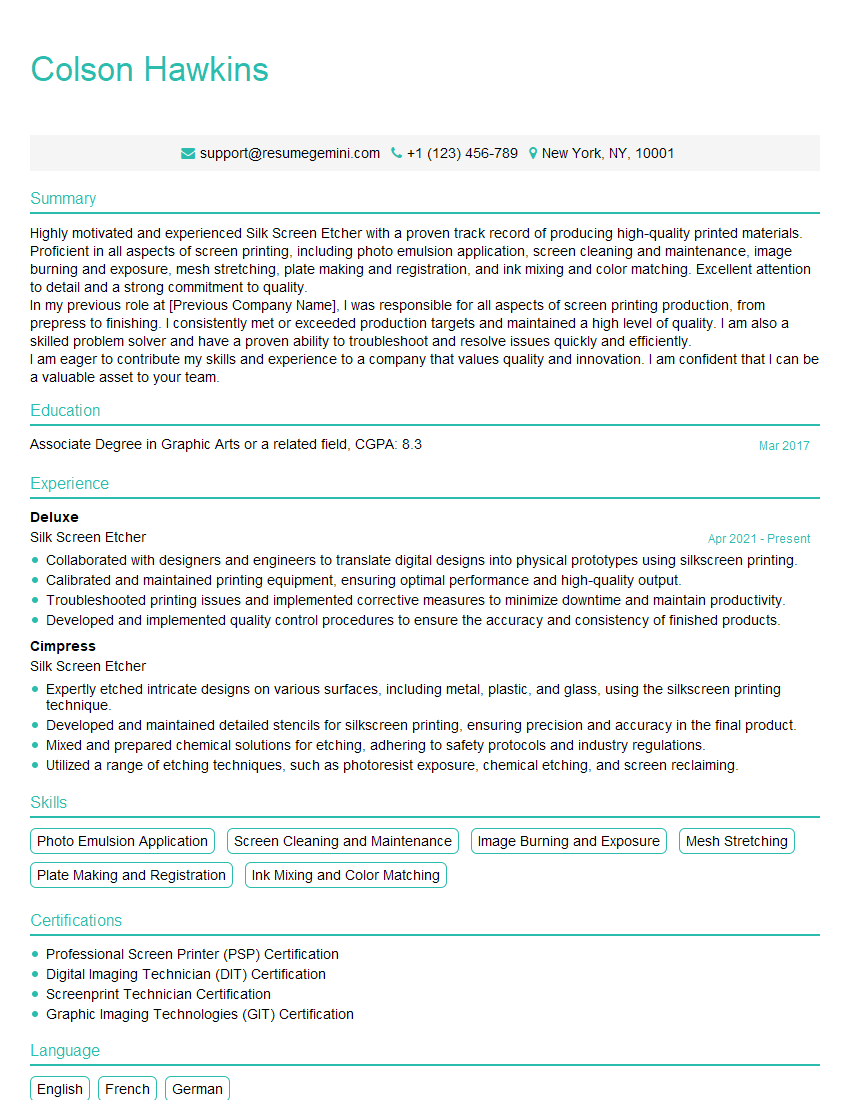

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Silk Screen Etcher

1. Describe the process of preparing a silk screen for etching.

The process of preparing a silk screen for etching involves several steps to ensure the screen is ready for the printing process:

- Degreasing: The screen is cleaned with a degreasing agent to remove any oils or dirt.

- Coating: A photosensitive emulsion is applied evenly onto the screen using a scoop coater or squeegee.

- Drying: The emulsion is allowed to dry thoroughly in a darkroom or under low lighting conditions.

- Exposing: The coated screen is exposed to ultraviolet light through a film positive, which transfers the desired image onto the emulsion.

- Developing: The exposed screen is rinsed with water to dissolve the unexposed emulsion, leaving behind the desired image.

2. What factors affect the quality of the etched design?

Precision of the Film Positive

- A high-quality film positive with sharp lines and accurate dimensions is crucial for creating a precise etched design.

Emulsion Thickness

- The thickness of the emulsion layer determines the depth and detail of the etched design.

Exposure Time

- Proper exposure time ensures that the emulsion is hardened sufficiently to withstand the etching process.

Etching Solution

- The type and concentration of the etching solution affect the etching rate and the quality of the design.

3. Explain the different types of etching solutions used in silk screen etching.

Various etching solutions can be used depending on the material of the screen and the desired etching effect:

- Acid-based: Acidic solutions like ferric chloride (FeCl3) are used for etching metal screens.

- Alkali-based: Alkaline solutions like sodium hydroxide (NaOH) are used for etching paper or fabric screens.

- Laser etching: A laser machine can be used to etch directly onto the screen, providing precise and intricate designs.

4. Describe the safety precautions to be observed while handling etching solutions.

Handling etching solutions requires strict adherence to safety protocols:

- Wear protective gear: Gloves, goggles, and an apron are essential to protect against chemical exposure.

- Proper ventilation: Ensure adequate ventilation to avoid inhaling fumes.

- Acid handling: Handle acid-based solutions with extreme caution and use designated containment areas.

- Neutralization: Neutralize etching solutions before disposal to minimize environmental impact.

- Disposal: Dispose of spent solutions according to local regulations to prevent contamination.

5. What techniques can be used to achieve different line widths and depths in silk screen etching?

To achieve variations in line widths and depths, several techniques can be employed:

- Varying exposure time: Longer exposure hardens the emulsion more, resulting in narrower and shallower lines.

- Multiple exposures: Repeated exposures can create thicker emulsion layers, leading to wider and deeper lines.

- Selective etching: Applying an etching resist to specific areas of the screen can protect them from the etching solution.

- Hand engraving: Manually carving into the etched screen can create unique textures and line variations.

6. What factors influence the choice of squeegee for silk screen printing?

Selecting the appropriate squeegee depends on several factors:

- Screen mesh count: The mesh count of the screen determines the size of the squeegee blade.

- Ink viscosity: Thicker inks require a harder squeegee blade for better control.

- Print area: The size of the print area influences the width and length of the squeegee blade.

- Squeegee angle: The angle at which the squeegee is held affects ink deposition and printing quality.

7. Describe the troubleshooting steps for resolving registration issues in silk screen printing.

Registration issues can be resolved through systematic troubleshooting:

- Inspect screens and films: Check for alignment errors between the screens and film positives.

- Adjust positioning: Reposition the screens or film positives to ensure proper alignment.

- Check registration marks: Verify that the registration marks on the screens and substrates match.

- Inspect printing equipment: Examine the press or carousel for any misalignments or mechanical issues.

- Calibrate printing machine: Ensure that the printing machine is calibrated accurately for precise registration.

8. How do you maintain and clean silk screens to ensure their longevity?

Maintaining silk screens involves proper cleaning and care:

- Regular cleaning: After each use, screens should be cleaned with water and a mild detergent to remove ink residue.

- Degreasing: Periodically degrease screens to remove any oils or contaminants that can interfere with ink adhesion.

- Emulsion removal: When changing images, remove the old emulsion thoroughly using a screen opener and pressure washer.

- Storage: Store screens in a dry, climate-controlled environment to prevent damage.

9. What are the advantages of using water-based inks over solvent-based inks in silk screen printing?

Water-based inks offer several benefits over solvent-based inks:

- Environmental friendliness: Water-based inks contain fewer volatile organic compounds (VOCs), making them more environmentally conscious.

- Ease of cleanup: Water-based inks can be cleaned up with water and soap, simplifying the cleaning process.

- Vibrant colors: Water-based inks provide a wide range of vibrant colors and can be easily mixed to create custom shades.

- Lower odor: Water-based inks emit less odor compared to solvent-based inks, creating a more comfortable work environment.

10. How do you optimize the curing process for silk screen printed fabrics to ensure maximum print durability?

Optimizing the curing process for silk screen printed fabrics is essential for print durability:

- Heat curing: Heat curing involves exposing the printed fabric to high temperatures to activate the ink’s binders and enhance its adhesion.

- UV curing: UV curing uses ultraviolet light to crosslink the ink’s polymers, resulting in a quick and durable finish.

- Air drying: Air drying is a slower process that allows the ink to evaporate and solidify over time.

- Follow ink manufacturer’s instructions: Refer to the ink manufacturer’s guidelines for specific curing recommendations and optimal curing conditions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Silk Screen Etcher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Silk Screen Etcher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Silk Screen Etchers are responsible for creating and maintaining silk screens used in the printing process. It involves transferring designs and patterns onto screens and using chemicals to etch the design into the screen. Here are some key job responsibilities:

1. Screen Preparation

Preparing the silk screens by stretching the fabric over a frame and applying a light-sensitive emulsion.

- Mounting silk fabric on a frame

- Applying light-sensitive emulsion

2. Design Transfer

Transferring designs onto the coated screens using various methods such as photoresist or hand-cut film.

- Creating photoresist or hand-cut film

- Exposing the screen to light to transfer the design

3. Screen Etching

Using chemicals to etch the design into the screen, creating open areas for ink to pass through.

- Selecting appropriate etching chemicals

- Soaking the screen in the etching solution

4. Screen Maintenance

Maintaining and cleaning the screens to ensure optimal quality printing.

- Inspecting screens for any damage

- Cleaning and unclogging screens

5. Quality Control

Checking the quality of the etched screens and ensuring they meet the specified standards.

- Conducting visual inspections

- Using measuring tools to check dimensions

Interview Tips

Preparing for a Silk Screen Etcher interview requires thorough research and practicing your responses. Here are some tips to help you ace the interview:

1. Research the Company and Role

Read about the company’s history, values, and the specific responsibilities of the Silk Screen Etcher role. This knowledge will demonstrate your interest and enthusiasm for the position.

- Visit the company website and social media pages

- Review the job description carefully

2. Highlight Relevant Experience

Emphasize your previous experience in silk screen etching or related fields. Quantify your accomplishments and provide specific examples of your skills.

- Describe any projects you’ve worked on

- Use numbers to illustrate your results

3. Showcase Technical Skills

Demonstrate your proficiency in the technical aspects of silk screen etching. Mention any certifications or training you have received and how they have enhanced your abilities.

- Discuss your expertise in chemical etching techniques

- Mention any knowledge of different types of emulsions and fabrics

4. Emphasize Attention to Detail

Silk screen etching requires meticulous attention to detail. Highlight your ability to work accurately and consistently to produce high-quality screens.

- Explain how you ensure precision in your work

- Provide examples of how you have resolved errors or defects in the past

5. Be Enthusiastic and Ask Questions

Show your enthusiasm for the role and express your eagerness to contribute to the team. Asking thoughtful questions about the company and the position demonstrates your engagement and interest.

- Share your passion for silk screen printing

- Inquire about the company’s growth plans and opportunities for professional development

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Silk Screen Etcher, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Silk Screen Etcher positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.