Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Silk Winding Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

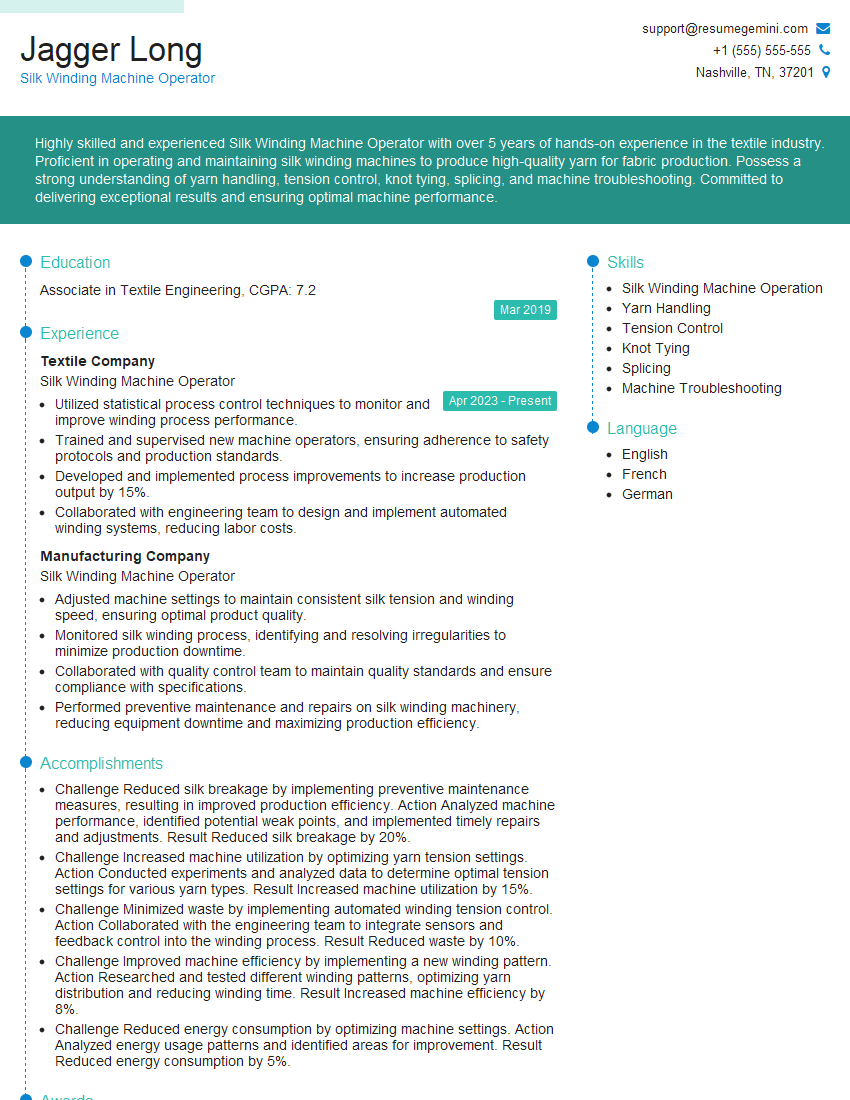

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Silk Winding Machine Operator

1. Explain the process of silk winding on a silk winding machine?

The process of silk winding on a silk winding machine involves several key steps:

- Creel Preparation: The silk yarn is unwound from bobbins or cones and placed on a creel, ensuring proper tension and alignment.

- Warping: The yarn is passed through a series of guide bars and tensioners to create a warp sheet, which is then wound onto a warp beam.

- Winding: The warp sheet is transferred to the winding machine, where it is wound onto a package in a specific pattern, typically a cross-wound or parallel-wound configuration.

- Tension Control: Throughout the process, the tension of the yarn is carefully controlled to ensure uniform winding and prevent breakage.

- Monitoring and Inspection: The winding process is monitored to detect any potential issues, such as yarn breakage, uneven winding, or package defects.

2. What are the different types of defects that can occur during silk winding, and how do you identify and correct them?

Types of Defects

- Yarn Breakage: This can be caused by excessive tension, weak yarn, or improper winding.

- Uneven Winding: This can result in package imbalance or poor fabric quality.

- Package Defects: These include soft or loose packages, uneven edges, or improper shape.

Identification and Correction

- Yarn Breakage: Check yarn tension, replace weak yarn, adjust winding parameters.

- Uneven Winding: Adjust tensioners, check guide bars for alignment, optimize winding speed.

- Package Defects: Stop the machine, inspect for winding errors, adjust machine settings or winding pattern.

3. How do you maintain and troubleshoot a silk winding machine?

Maintaining and troubleshooting a silk winding machine involves:

- Regular Cleaning and Inspection: Clean machine components, check tensioners, guide bars, and sensors for wear or damage.

- Lubrication: Lubricate moving parts according to manufacturer’s instructions to reduce friction and prevent overheating.

- Calibration: Calibrate tensioners, sensors, and other critical components to ensure accurate winding.

- Troubleshooting: Diagnose and resolve issues such as yarn breakage, uneven winding, or machine stoppages by analyzing error codes or performing diagnostic tests.

4. Describe the quality control procedures involved in silk winding?

Quality control procedures for silk winding include:

- Yarn Inspection: Inspect incoming yarn for defects, strength, and uniformity.

- In-Process Monitoring: Observe winding process for any irregularities or defects.

- Package Inspection: Measure and inspect packages for weight, dimensions, and surface quality.

- Testing: Conduct tests on finished packages to ensure they meet specified requirements for strength, tension, and winding accuracy.

- Documentation: Record inspection results and maintain traceability for quality assurance.

5. What safety precautions should be followed when operating a silk winding machine?

Safety precautions for operating a silk winding machine include:

- Machine Guards: Ensure machine guards are in place and operational to prevent entanglement or injury.

- Electrical Safety: Check electrical connections, ground the machine properly, and avoid loose wires.

- Personal Protective Equipment: Wear appropriate clothing, gloves, and safety glasses.

- Ergonomics: Maintain proper posture and take regular breaks to avoid strain or injury.

- Emergency Procedures: Familiarize yourself with emergency stop procedures and evacuation routes.

6. How do you optimize the efficiency of a silk winding machine?

Optimizing the efficiency of a silk winding machine involves:

- Proper Machine Setup: Ensure correct tension settings, guide bar alignment, and winding speed.

- Yarn Management: Minimize yarn breaks by ensuring smooth yarn flow and proper tension.

- Machine Maintenance: Perform regular maintenance to keep the machine in good working order.

- Process Optimization: Experiment with different winding parameters to find the most efficient combination for the specific yarn and package requirements.

- Operator Training: Provide training to operators to ensure they are skilled in efficient machine operation.

7. Describe the role of automation in modern silk winding machines?

Automation in modern silk winding machines plays a crucial role in:

- Process Control: Automated systems monitor and control winding parameters such as tension, speed, and package shape.

- дефект Inspection: Automated defect detection systems identify yarn breaks and other defects during winding.

- Data Collection: Machines collect data on winding parameters, yarn usage, and package quality for analysis and optimization.

- Operator Interface: Automated systems provide user-friendly interfaces for easy machine operation and troubleshooting.

- Increased Productivity: Automation reduces manual labor, increases winding speed, and improves overall efficiency.

8. What are the key factors to consider when selecting a silk winding machine?

Key factors to consider when selecting a silk winding machine include:

- Yarn Type and Requirements: Different yarns require specific winding parameters and machine capabilities.

- Package Specifications: The machine should be able to produce packages in the desired size, shape, and density.

- Production Volume: The machine should meet the required production capacity.

- Automation Level: Determine the desired level of automation, from manual to fully automated.

- Cost and Return on Investment: Consider the purchase price, operating costs, and potential return on investment.

9. Describe the different types of silk used in the textile industry?

Types of Silk

- Mulberry Silk: Known for its high quality, luster, and durability; used in high-end garments, accessories, and home textiles.

- Tussah Silk: Has a natural golden color and a textured surface; used in casual wear, upholstery, and home furnishings.

- Eri Silk: Known as “peace silk” because it is harvested without harming the silkworms; has a soft, hairy texture; used in shawls, scarves, and blankets.

- Muga Silk: A rare and valuable type of silk produced only in Assam, India; has a golden-yellow color and is used in traditional garments and textiles.

10. What career advancement opportunities are available for a Silk Winding Machine Operator?

Career advancement opportunities for a Silk Winding Machine Operator may include:

- Senior Silk Winding Machine Operator: Supervising other operators and ensuring production targets are met.

- Machine Maintenance Technician: Responsible for maintaining and troubleshooting silk winding machines.

- Textile Production Supervisor: Managing a team of operators in a textile production department.

- Quality Control Inspector: Ensuring the quality of silk products at various stages of production.

- Textile Engineer: Designing, developing, and optimizing textile production processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Silk Winding Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Silk Winding Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Silk Winding Machine Operator plays a crucial role in the textile industry, ensuring the efficient winding of silk onto bobbins. Key responsibilities of this role include:

1. Machine Operation

Operate and monitor silk winding machines, ensuring smooth and efficient functioning.

- Set up and adjust machines according to specifications.

- Load raw silk onto machines and initiate the winding process.

2. Quality Control

Maintain high quality standards by monitoring and inspecting silk wound on bobbins.

- Check for proper tension, diameter, and alignment of silk.

- Identify and rectify any defects or inconsistencies to ensure optimal quality.

3. Maintenance and Troubleshooting

Perform regular maintenance tasks and troubleshoot any issues with winding machines.

- Clean and lubricate machines to ensure proper operation.

- Identify and resolve minor machine issues to minimize downtime.

4. Production Optimization

Monitor and optimize production processes to achieve efficiency targets.

- Track machine performance and identify areas for improvement.

- Collaborate with other team members to streamline workflows and enhance productivity.

Interview Tips

To ace the interview for a Silk Winding Machine Operator position, consider the following tips:

1. Research the Company and Role

Familiarize yourself with the company’s history, values, and the specific requirements of the Silk Winding Machine Operator role.

- Visit the company website and review their mission statement, products or services, and any relevant news.

- Thoroughly read the job description and identify the key responsibilities and qualifications required.

2. Highlight Relevant Experience and Skills

Emphasize your experience in operating silk winding machines or similar equipment. Showcase your skills in quality control, troubleshooting, and production optimization.

- Provide specific examples from your previous roles to demonstrate your proficiency.

- Quantify your accomplishments whenever possible, using metrics to illustrate your impact.

3. Demonstrate a Strong Work Ethic

Convey your commitment to maintaining a clean and safe work environment. Emphasize your attention to detail and ability to work independently and as part of a team.

- Share instances where you went above and beyond to ensure quality and efficiency.

- Describe your experience in working effectively in a production-oriented environment.

4. Be Enthusiastic and Ask Informed Questions

Show your genuine interest in the role and the company. Ask thoughtful questions about the production process, company culture, and opportunities for professional growth.

- Prepare specific questions that demonstrate your understanding of the industry and the company’s operations.

- Convey your enthusiasm for the opportunity and your eagerness to contribute to the team.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Silk Winding Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!