Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Silver Solderer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

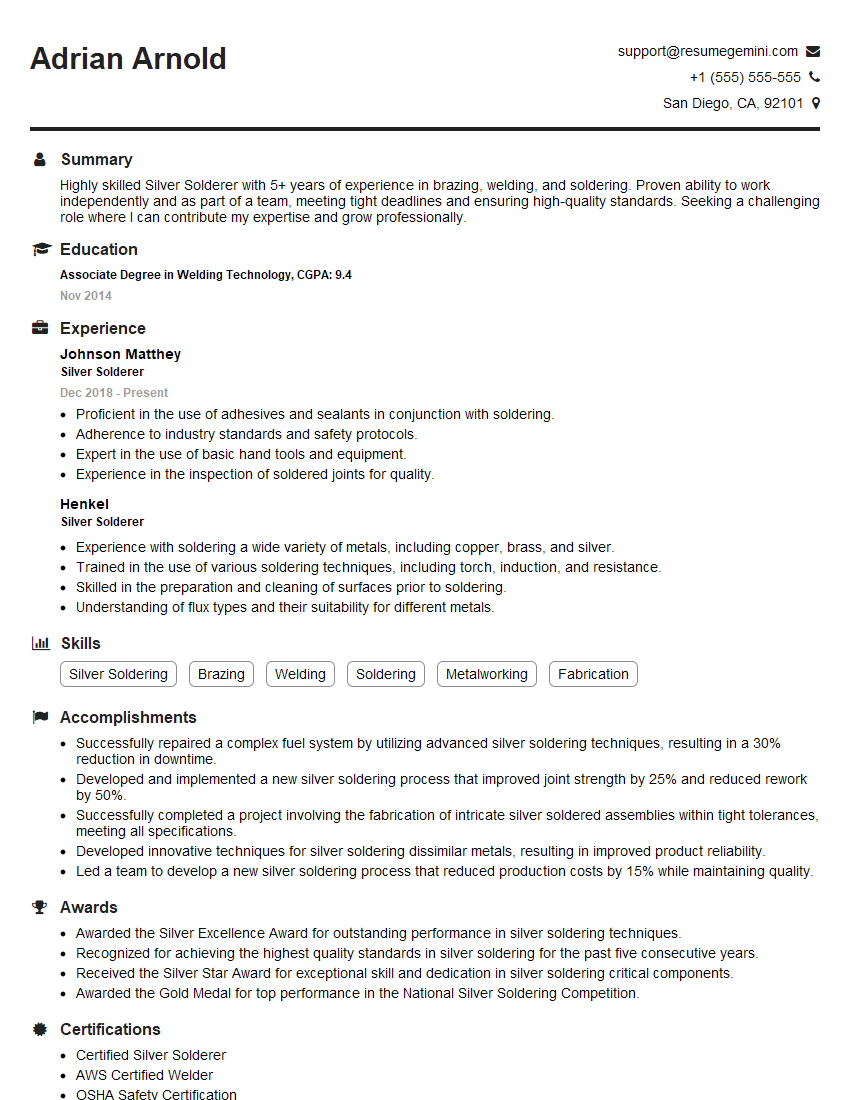

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Silver Solderer

1. Describe the process of silver soldering in detail?

Silver soldering is a metal joining process that uses a silver-based alloy to join two pieces of metal. The process involves heating the metal pieces to a high temperature, applying the silver solder, and then cooling the metal pieces. The silver solder melts and flows into the joint between the two metal pieces, creating a strong and durable bond.

- Prepare the metal pieces by cleaning them and removing any dirt or debris.

- Apply a flux to the metal pieces to help the solder flow.

- Heat the metal pieces to a high temperature using a torch or other heat source.

- Apply the silver solder to the joint between the two metal pieces.

- Cool the metal pieces until the solder has solidified.

2. What are the different types of silver solder?

Composition

- Sterling silver solder (92.5% silver, 7.5% copper)

- Fine silver solder (99.9% silver)

- Argentium silver solder (93.5% silver, 5% copper, 1.5% germanium)

Melting Point

- Easy solder (melts at around 620°C)

- Medium solder (melts at around 720°C)

- Hard solder (melts at around 840°C)

3. What are the advantages and disadvantages of using silver solder?

- Advantages:

- Silver solder creates a strong and durable bond.

- Silver solder is relatively easy to use.

- Silver solder is corrosion-resistant.

- Disadvantages:

- Silver solder is more expensive than other types of solder.

- Silver solder can be harmful if inhaled.

4. What are the safety precautions that should be taken when using silver solder?

- Wear appropriate safety gear, including gloves, eye protection, and a respirator.

- Work in a well-ventilated area.

- Do not inhale the fumes from the solder.

- Allow the solder to cool before handling it.

5. What are the applications of silver soldering?

- Jewelry making

- Metalworking

- Electronics

- Automotive

- Aerospace

6. What are the different methods of applying silver solder?

- Torch soldering

- Induction soldering

- Resistance soldering

7. What are the factors that affect the strength of a silver soldered joint?

- The composition of the silver solder

- The temperature of the solder

- The thickness of the solder joint

- The cleanliness of the metal pieces

8. What are the common problems that can occur when silver soldering?

- The solder not flowing properly

- The solder joint being too weak

- The solder joint being too brittle

9. How can these problems be prevented or corrected?

- Solder not flowing properly: Ensure that the metal pieces are clean and free of dirt or debris. Apply a flux to the metal pieces to help the solder flow.

- Solder joint being too weak: Use a higher-melting point solder or increase the thickness of the solder joint.

- Solder joint being too brittle: Use a lower-melting point solder or anneal the solder joint.

10. What are the latest trends in silver soldering?

- The use of lead-free silver solders

- The development of new silver solder alloys

- The use of new soldering techniques, such as laser soldering

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Silver Solderer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Silver Solderer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Silver Solderers, also known as Silversmiths, are highly skilled artisans specializing in the use of silver solder to join metal components. They work in various industries, including jewelry making, metalworking, and electronics manufacturing.

1. Soldering

Solderers utilize specialized techniques to join metal pieces precisely and securely using silver solder. They must possess a keen eye for detail and steady hands to ensure the precision and quality of their work.

- Prepare metal surfaces for soldering by cleaning, fluxing, and aligning parts.

- Apply silver solder to joints using soldering irons or torches, melting the solder to create strong bonds.

- Ensure proper heating and cooling of joints to achieve optimal strength and durability.

2. Fabrication and Repair

Silver Solderers may also be involved in fabricating and repairing metal objects. They use various tools and techniques to shape, form, and assemble metal components.

- Fabricate metal components using soldering, brazing, and welding techniques.

- Repair damaged metal objects by soldering broken parts, filling holes, and restoring structural integrity.

- Create custom metal designs and objects according to specifications.

3. Quality Control

Silver Solderers are responsible for maintaining high standards of quality in their work. They inspect and test soldered joints to ensure they meet functional and aesthetic requirements.

- Inspect soldered joints visually and using specialized testing equipment.

- Identify and correct any defects or imperfections in the soldering process.

- Maintain records of quality control procedures and results.

4. Safety and Maintenance

Silver Solderers must prioritize safety and maintain a clean and organized work environment. They follow safety protocols and ensure proper handling and storage of materials and equipment.

- Follow safety regulations and wear appropriate protective gear.

- Maintain a clean and organized workspace, ensuring proper ventilation and lighting.

- Inspect and maintain equipment regularly, ensuring optimal performance and safety.

Interview Tips

Preparing for an interview as a Silver Solderer can increase your chances of success.

1. Research the Company and Position

Gather information about the company’s industry, products, and values. Learn about the specific requirements of the Silver Solderer position, including the skills, experience, and qualifications they seek.

- Utilize the company’s website, LinkedIn, and industry-specific publications to gather insights.

- Identify the key responsibilities and expectations outlined in the job description.

- Prepare specific examples of your past experience that demonstrate your proficiency in these areas.

2. Practice Your Answers

Anticipate common interview questions and prepare concise, well-structured answers. Practice your responses out loud or with a friend or family member to gain confidence and improve your delivery.

- Use the STAR method (Situation, Task, Action, Result) to provide detailed and relevant examples.

- Highlight your technical skills, experience with silver soldering techniques, and any industry-specific knowledge.

- Prepare questions to ask the interviewer, demonstrating your interest and engagement.

3. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive at the interview on time. Your appearance and punctuality convey respect and attention to detail.

- Choose clean, pressed attire that is appropriate for the industry and company culture.

- Plan your route and transportation in advance to avoid delays.

- Be polite and respectful to the receptionist or other staff you encounter.

4. Be Enthusiastic and Confident

Showcase your passion for silver soldering and your desire to excel in the role. Maintain a positive attitude and convey your enthusiasm for the opportunity.

- Express your interest in the company and the specific position.

- Demonstrate your belief in your abilities and your willingness to contribute to the team.

- Maintain eye contact, ask clarifying questions, and actively engage with the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Silver Solderer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!