Are you gearing up for a career in Silvering Department Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Silvering Department Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

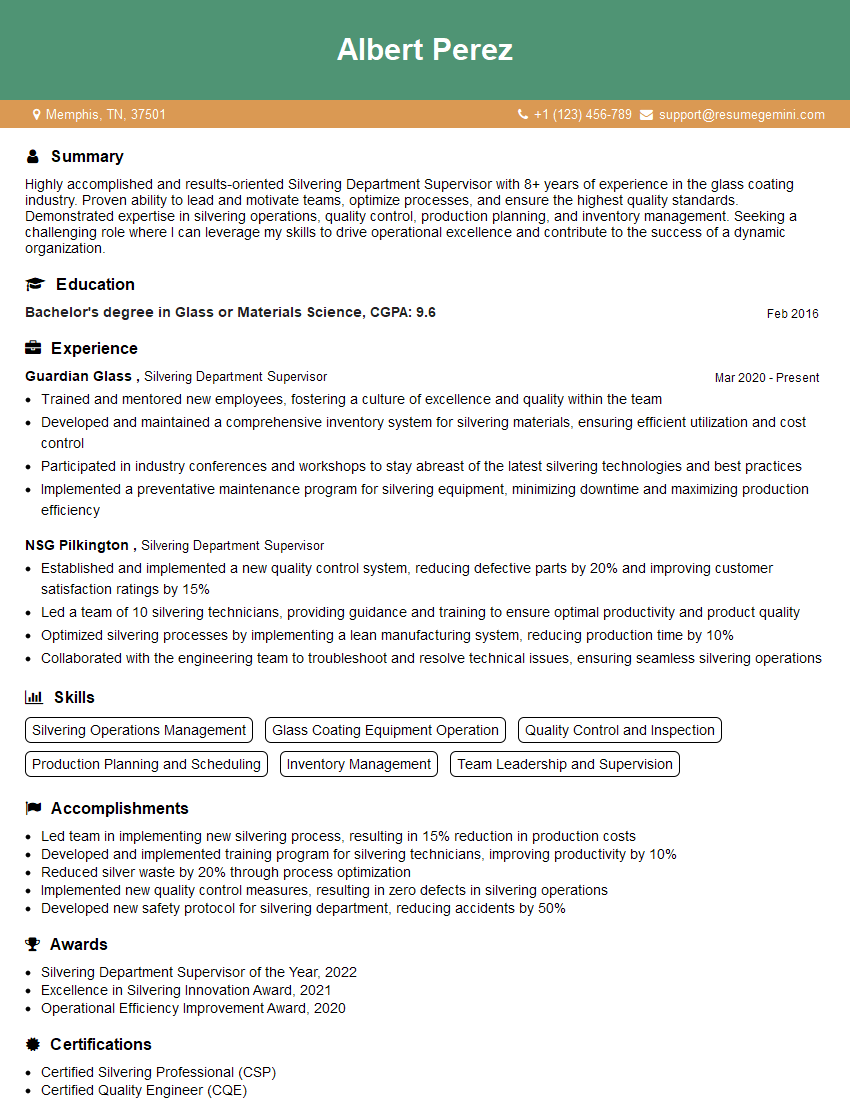

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Silvering Department Supervisor

1. What are the key responsibilities of a Silvering Department Supervisor?

As a Silvering Department Supervisor, I would be responsible for the following key tasks:

- Overseeing all aspects of the silvering process, ensuring that products meet specifications and quality standards.

- Monitoring and maintaining silvering equipment, including cleaning, calibration, and troubleshooting.

- Training and supervising team members, providing guidance and support to ensure they are skilled and up to date on best practices.

2. What are the different types of silvering techniques and their applications?

Chemical Silvering

- Common technique used for decorative purposes

- Involves coating a surface with a chemical solution, followed by a reducing agent to form a silver mirror

Electroless Silvering

- Used for industrial applications, such as electronics and jewelry

- Involves depositing a layer of silver onto a surface without the use of an electric current

Electrolytic Silvering

- Similar to electroless silvering, but uses an electric current to deposit the silver layer

- Creates a thicker and more durable coating

3. Can you describe the steps involved in the silvering process?

The silvering process typically involves the following steps:

- Surface Preparation: Cleaning and preparing the surface to ensure proper adhesion.

- Sensitization: Applying a sensitizing solution to make the surface receptive to silver ions.

- Activation: Using an activator to further enhance the surface’s reactivity.

- Silvering: Immersing the surface in a silver plating solution, allowing silver ions to deposit onto the surface.

- Rinsing and Drying: Rinsing the silvered surface to remove excess chemicals and drying it to prevent oxidation.

4. What are some of the challenges you have faced as a Silvering Department Supervisor and how did you overcome them?

One challenge I faced was maintaining consistent silver coating quality. To overcome this, I implemented a rigorous quality control process, including regular inspections and testing, to ensure that products met specifications.

Another challenge was optimizing production efficiency. I analyzed the silvering process and identified bottlenecks. I then introduced lean manufacturing principles, such as reducing waste and improving workflow, to streamline operations and increase productivity.

5. How do you ensure that silvering operations comply with environmental regulations?

I am committed to adhering to all applicable environmental regulations. I ensure that:

- Silvering chemicals are handled and disposed of properly to minimize environmental impact.

- Wastewater from the silvering process is treated to remove contaminants before being discharged.

- Regular environmental audits are conducted to identify and mitigate any potential risks.

6. What are the key factors to consider when selecting silvering materials?

When selecting silvering materials, I consider the following factors:

- Purity: The purity of the silver used affects the quality and durability of the coating.

- Thickness: The thickness of the silver coating determines its resistance to wear and tear.

- Adhesion: The adhesion of the silver coating to the substrate is crucial for long-lasting results.

- Cost: The cost of the materials must be balanced against the desired performance and durability.

7. How do you manage and train your team to ensure high-quality silvering?

I believe in empowering my team and fostering a culture of continuous improvement. I provide comprehensive training to ensure that team members are proficient in all aspects of the silvering process.

Regular performance evaluations and feedback help identify areas for growth and development. I also encourage teamwork and collaboration to share knowledge and best practices.

8. How do you stay up to date with advancements in silvering technology?

I am committed to continuous learning and professional development. I regularly attend industry conferences and workshops to gain insights into the latest advancements in silvering technology.

I also subscribe to trade publications and research journals to stay informed about new techniques, materials, and equipment.

9. What are the safety precautions that must be taken when working with silvering chemicals?

Working with silvering chemicals requires adherence to strict safety protocols. I ensure that:

- Proper personal protective equipment (PPE), such as gloves, goggles, and respirators, is worn.

- Chemicals are handled and stored according to manufacturer’s instructions and in designated areas.

- Emergency response plans are in place and all team members are trained on safety procedures.

10. How do you ensure that silvering operations meet customer specifications and expectations?

Meeting customer specifications is paramount. I work closely with customers to understand their requirements and ensure that our processes align with their expectations.

Regular quality checks and inspections are conducted to verify that products meet specifications. I also encourage customer feedback to continuously improve our processes and exceed their expectations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Silvering Department Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Silvering Department Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Silvering Department Supervisor plays a crucial role in overseeing and managing the silvering process within the organization. Their primary responsibilities include:

1. Silvering Process Management

Directing daily silvering operations, ensuring adherence to established standards and procedures.

- Monitoring and calibrating silvering equipment to optimize quality

- Troubleshooting and resolving technical issues related to the silvering process

2. Quality Control and Inspection

Establishing and implementing quality control measures to ensure the production of high-quality silvered products.

- Conducting regular inspections of silvered products and identifying deviations from standards

- Working closely with the quality assurance department to address and resolve quality issues

3. Team Management and Development

Leading and motivating a team of silvering operators, providing guidance and support.

- Setting performance goals and providing regular feedback to improve employee performance

- Identifying and addressing employee training and development needs

4. Process Improvement and Innovation

Continuously evaluating and improving the silvering process, seeking out opportunities for optimization.

- Implementing new technologies and techniques to enhance productivity and efficiency

- Collaborating with other departments to identify and address areas of process improvement

Interview Tips

To help you ace the interview for the Silvering Department Supervisor position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry standing. Understand the specific requirements and responsibilities of the Silvering Department Supervisor role.

- Visit the company’s website and read about their mission, values, and recent developments.

- Study the job description carefully and identify the key skills and experiences that the interviewer is seeking.

2. Highlight Relevant Skills and Experience

Tailor your resume and cover letter to emphasize the skills and experience that are most relevant to the job. Quantify your accomplishments whenever possible.

- Provide specific examples of your involvement in silvering operations, quality control, team management, and process improvement.

- Use numerical data to demonstrate your results, such as the percentage improvement in product quality or the number of successful process innovations you implemented.

3. Prepare Answers to Common Interview Questions

Anticipate the typical questions asked in job interviews and prepare well-structured answers that showcase your suitability for the role.

- Questions related to your technical expertise in silvering, quality control, and process management

- Questions about your leadership and team management style, and how you motivate and develop employees

4. Practice Your Interview Techniques

Conduct mock interviews with a friend, family member, or career counselor to practice answering questions and presenting yourself confidently.

- Time yourself to ensure you can provide concise and engaging answers within the typical time limits for interview responses.

- Ask for feedback on your body language, tone of voice, and overall presentation to identify areas for improvement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Silvering Department Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.