Are you gearing up for a career in Singe Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Singe Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

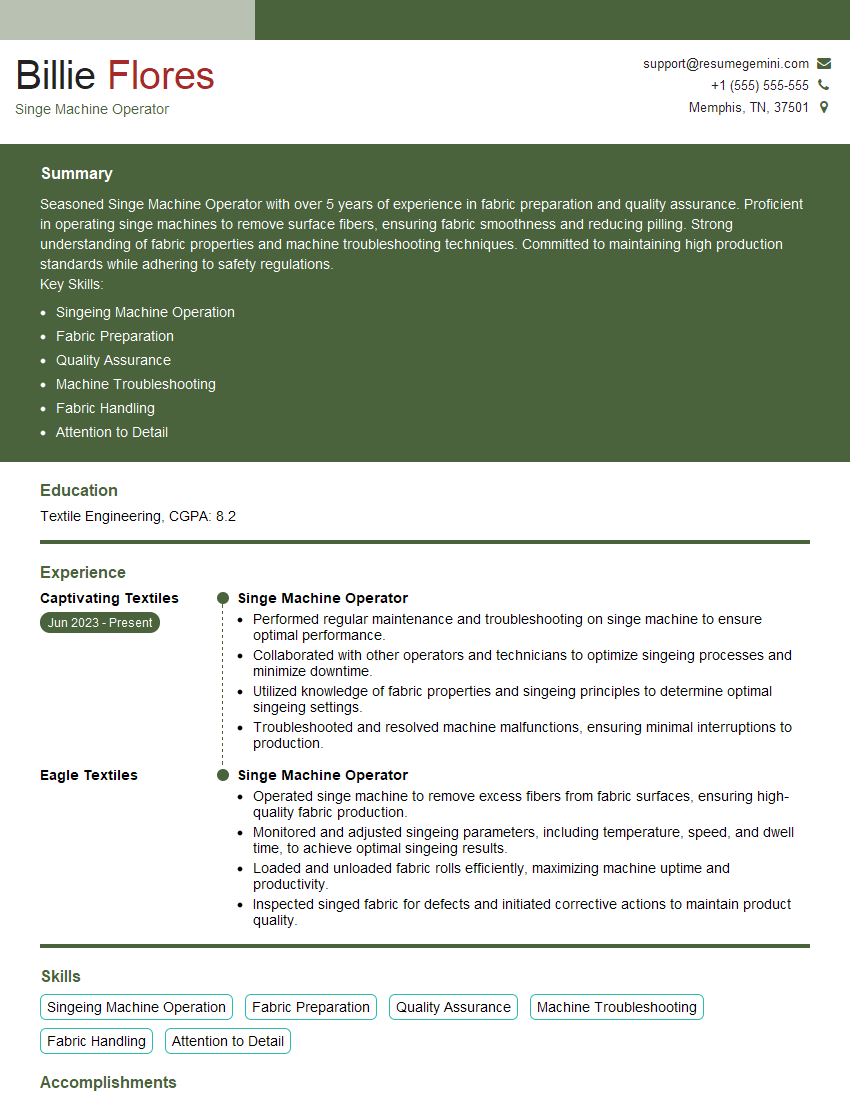

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Singe Machine Operator

1. What are the safety precautions one should take while operating a singe machine?

The following safety precautions should be taken while operating a singe machine:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a mask.

- Keep the work area clean and free of debris.

- Inspect the machine before each use to ensure it is in good working condition.

- Never operate the machine at a speed that exceeds the manufacturer’s recommendations.

- Keep your hands away from the singeing flame.

- Do not leave the machine unattended while it is operating.

- Follow all manufacturer’s instructions for safe operation.

2. How do you adjust the singeing flame on a singe machine?

The singeing flame on a singe machine can be adjusted by turning the gas valve. Turning the valve clockwise will increase the flame size, while turning it counterclockwise will decrease the flame size. The flame should be adjusted so that it is large enough to singe the fabric without damaging it.

3. What are the different types of singeing machines?

There are two main types of singeing machines: open-flame singeing machines and closed-flame singeing machines.

- Open-flame singeing machines use a direct flame to singe the fabric.

- Closed-flame singeing machines use a heated drum to singe the fabric.

Open-flame singeing machines are less expensive and easier to operate than closed-flame singeing machines. However, they can also be more dangerous and can produce more fumes.

4. What are the advantages of using a singe machine?

There are several advantages to using a singe machine, including:

- Improved fabric quality: Singeing removes surface hairs and impurities from the fabric, which results in a smoother and more even surface.

- Increased fabric strength: Singeing strengthens the fabric by removing weak fibers.

- Reduced fabric shrinkage: Singeing reduces the amount of shrinkage that occurs when the fabric is washed.

- Improved fabric appearance: Singeing gives the fabric a more uniform and finished appearance.

5. What are the disadvantages of using a singe machine?

There are also some disadvantages to using a singe machine, including:

- Safety concerns: Singe machines can be dangerous to operate, and it is important to take the necessary safety precautions to avoid injury.

- Potential for fabric damage: If the singeing flame is not adjusted properly, it can damage the fabric.

- Fumes and odors: Singeing can produce fumes and odors that can be harmful to health.

- Cost: Singe machines can be expensive to purchase and operate.

6. What are the different types of fabric that can be singed?

A wide variety of fabrics can be singed, including:

- Cotton

- Linen

- Wool

- Silk

- Synthetic fabrics

The type of fabric will determine the specific settings that need to be used on the singe machine.

7. What is the purpose of singeing fabric?

Singeing fabric serves several purposes, including:

- Removing surface hairs and impurities

- Strengthening the fabric

- Reducing fabric shrinkage

- Improving fabric appearance

- Removing creases and wrinkles

- Creating a smooth and uniform surface

8. What are the different grades of singeing?

There are three main grades of singeing:

- Light singeing: This type of singeing removes only the surface hairs and impurities.

- Medium singeing: This type of singeing removes the surface hairs, impurities, and some of the weaker fibers.

- Heavy singeing: This type of singeing removes the surface hairs, impurities, and most of the weaker fibers.

The grade of singeing that is used will depend on the type of fabric and the desired results.

9. What are the different factors that affect the singeing process?

The singeing process is affected by several factors, including:

- The type of fabric

- The grade of singeing

- The speed of the fabric

- The temperature of the flame

- The distance between the flame and the fabric

It is important to carefully control all of these factors in order to achieve the desired results.

10. What are the common problems that can occur during singeing?

Several common problems can occur during singeing, including:

- Fabric damage: If the singeing flame is not adjusted properly, it can damage the fabric.

- Fumes and odors: Singeing can produce fumes and odors that can be harmful to health.

- Uneven singeing: If the fabric is not passed through the singeing flame evenly, it can result in uneven singeing.

- Singing marks: If the fabric is not held at the correct distance from the flame, it can result in singing marks.

It is important to be aware of these potential problems and to take steps to prevent them from occurring.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Singe Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Singe Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Singe Machine Operators play a crucial role in the production of textiles by removing surface fibers from fabrics using controlled heat. Their primary responsibilities include:

1. Operating Singe Machines

Operate and maintain singe machines, ensuring optimal performance and production efficiency.

2. Fabric Preparation

Prepare fabrics for singeing by ensuring proper tension, alignment, and feeding into the machine.

3. Monitoring Singeing Process

Monitor the singeing process closely to ensure uniform removal of surface fibers and prevent fabric damage.

4. Fabric Inspection

Inspect singed fabrics for quality, ensuring that they meet industry standards and customer specifications.

5. Machine Maintenance

Perform routine maintenance on singe machines, including cleaning, lubrication, and replacement of worn or damaged parts.

6. Production Optimization

Collaborate with other team members to optimize production processes, reduce downtime, and improve efficiency.

Interview Tips

To ace an interview for a Singe Machine Operator position, candidates should prepare effectively. Here are some tips:

1. Research the Company and Role

Thoroughly research the company, industry, and specific role to demonstrate your interest and understanding of the position.

2. Highlight Relevant Skills and Experience

Emphasize your experience in operating singe machines, fabric handling, and quality control. Showcase your ability to work in a fast-paced environment and attention to detail.

3. Prepare for Technical Questions

Study the principles of singeing, machine operation, and common maintenance procedures. Practice answering questions about fabric types, machine settings, and troubleshooting techniques.

4. Practice Problem Solving

Prepare for hypothetical scenarios that may arise on the job, such as fabric quality issues, machine malfunctions, or production delays. Demonstrate your problem-solving and decision-making skills.

5. Emphasize Safety and Compliance

Highlight your commitment to safety and compliance with industry regulations. Explain your understanding of safety protocols and procedures for handling and operating singeing machines.

6. Dress Professionally and Arrive on Time

Dress appropriately for the interview and arrive punctually. This demonstrates respect for the interviewers and your interest in the opportunity.

7. Ask Questions

Prepare thoughtful questions for the interviewers to show your interest and engagement. This also allows you to clarify any aspects of the role or company culture.

8. Follow Up

After the interview, send a brief thank-you note to the interviewers, reiterating your interest in the position and thanking them for their time. This shows your professionalism and appreciation.

Next Step:

Now that you’re armed with the knowledge of Singe Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Singe Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini