Are you gearing up for a career in Singe Winder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Singe Winder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

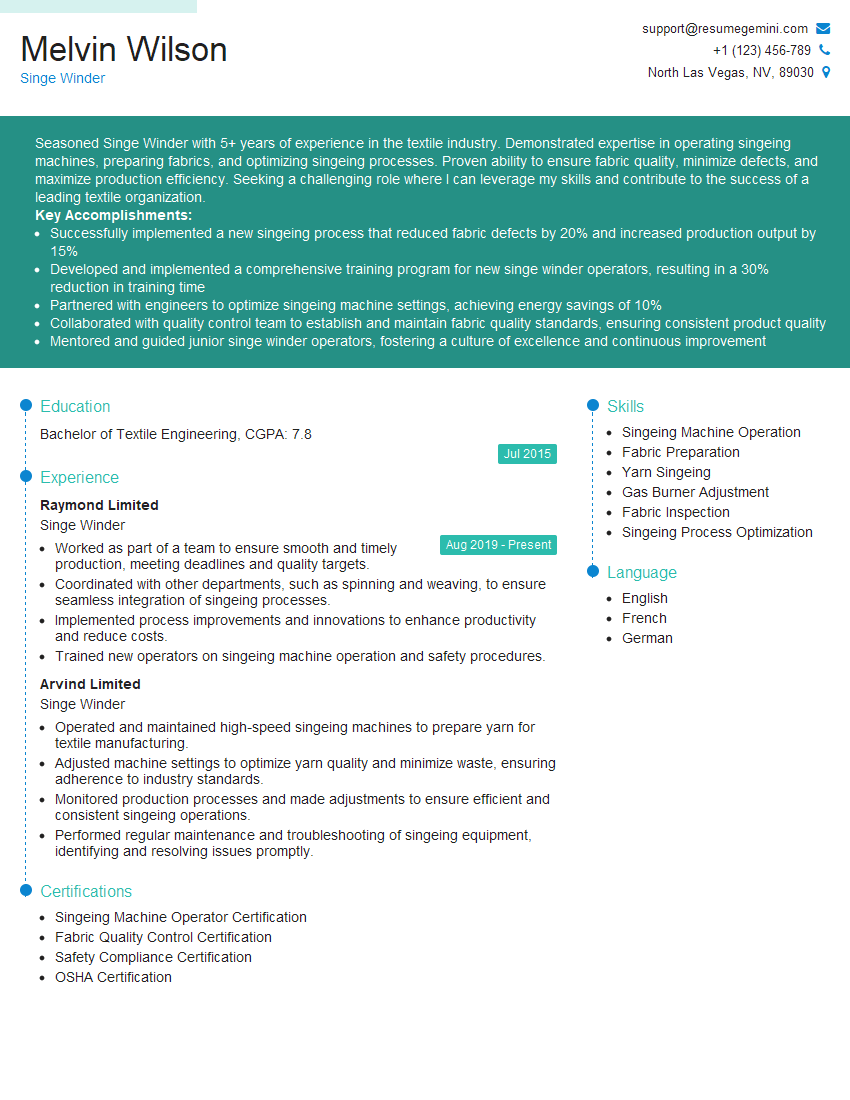

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Singe Winder

1. What are the key components of a singe winder, and how do they work together?

The key components of a singe winder are:

- Creel: The creel holds the yarn supply packages.

- Tensioner: The tensioner controls the tension of the yarn as it is wound onto the package.

- Traverse mechanism: The traverse mechanism moves the yarn back and forth across the package to create a uniform wind.

- Winder: The winder is a rotating drum that winds the yarn onto the package.

These components work together to create a uniform, high-quality wind that is suitable for downstream processes.

2. How do you calculate the traverse rate of a singe winder?

Calculate the yarn speed

- Yarn speed = (Package circumference) / (Winding speed)

Calculate traverse rate

- Traverse rate = Yarn speed / (Number of traverse cycles per minute / 60)

3. What are the different types of singe winders, and what are their advantages and disadvantages?

The different types of singe winders are:

- Drum winders: Drum winders are the most common type of singe winder. They are simple in design and easy to operate. However, they can only produce a limited range of package sizes.

- Cone winders: Cone winders are used to produce conical packages. This type of package is ideal for downstream processes such as dyeing and weaving. However, cone winders are more complex in design and more expensive to operate than drum winders.

- Cross winders: Cross winders are used to produce cross-wound packages. This type of package is ideal for downstream processes such as knitting and embroidery. However, cross winders are more complex in design and more expensive to operate than drum and cone winders.

4. How do you maintain a singe winder to ensure optimal performance?

To maintain a singe winder to ensure optimal performance, it is important to:

- Keep the winder clean and free of dust and debris.

- Inspect the winder regularly for any signs of wear or damage.

- Lubricate the winder according to the manufacturer’s instructions.

- Calibrate the winder regularly to ensure that it is winding the yarn to the correct tension and traverse rate.

- Train operators on how to use the winder properly.

5. What are the safety precautions that need to be taken when operating a singe winder?

When operating a singe winder, it is important to take the following safety precautions:

- Wear appropriate safety gear, such as safety glasses and gloves.

- Keep hands and loose clothing away from moving parts.

- Do not operate the winder if it is damaged or not functioning properly.

- Be aware of the location of the emergency stop button.

- Follow all manufacturer’s instructions for safe operation.

6. What are the common problems that can occur with singe winders, and how can they be solved?

Common problems that can occur with singe winders include:

- Yarn breakage: Yarn breakage can be caused by a variety of factors, such as incorrect tension, worn or damaged parts, or improper handling of the yarn.

- Uneven winding: Uneven winding can be caused by incorrect traverse rate, worn or damaged parts, or improper handling of the yarn.

- Package defects: Package defects can be caused by a variety of factors, such as incorrect tension, worn or damaged parts, or improper handling of the yarn.

These problems can be solved by:

- Inspecting the winder for any signs of wear or damage.

- Adjusting the tension and traverse rate according to the manufacturer’s instructions.

- Properly handling the yarn.

- Replacing worn or damaged parts.

7. What are the latest trends in singe winder technology?

The latest trends in singe winder technology include:

- Increased automation: Singe winders are becoming increasingly automated, which reduces the need for operator intervention and improves efficiency.

- Improved tension control: New tension control systems are being developed that provide more precise control over the tension of the yarn, which results in improved package quality.

- Increased winding speeds: Singe winders are being developed that can wind yarn at higher speeds, which increases productivity.

- Reduced energy consumption: New singe winder designs are being developed that consume less energy, which reduces operating costs.

8. How do you stay up-to-date on the latest singe winder technology?

I stay up-to-date on the latest singe winder technology by:

- Reading industry publications and attending trade shows.

- Networking with other singe winder operators and engineers.

- Participating in online forums and discussion groups.

- Attending training courses offered by singe winder manufacturers.

9. What are your strengths and weaknesses as a singe winder operator?

Strengths:

- I have extensive experience operating singe winders.

- I have a strong understanding of singe winder technology.

- I am able to identify and solve common singe winder problems.

- I am a team player and I am always willing to help others.

Weaknesses:

- I do not have any experience operating the latest singe winder models.

- I am not fluent in any foreign languages.

10. Why should we hire you as a singe winder operator?

I believe that I am the best candidate for this position because I have the skills and experience that you are looking for.

- I have extensive experience operating singe winders.

- I have a strong understanding of singe winder technology.

- I am able to identify and solve common singe winder problems.

- I am a team player and I am always willing to help others.

- I am eager to learn new things and I am always looking for ways to improve my skills.

I am confident that I can make a significant contribution to your company as a singe winder operator.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Singe Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Singe Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Singe Winder is a highly skilled professional responsible for operating singeing machines, which remove protruding fibers and surface impurities from fabrics. Their primary tasks involve ensuring machine efficiency, maintaining fabric quality, and adhering to safety protocols.

1. Machine Operation and Maintenance

Singe winders operate singeing machines, adjusting machine settings to achieve optimal singeing results. They regularly inspect and maintain machines, performing minor repairs and replacements to ensure smooth operation and prevent breakdowns.

2. Fabric Preparation and Handling

They prepare fabrics for singeing by inspecting them for defects and removing any foreign objects or attachments. They also control the tension of fabrics during the singeing process to prevent creases or distortions.

3. Quality Control

Singe Winders inspect singed fabrics to ensure they meet quality standards. They check for proper singeing, smoothness, and absence of defects or impurities. They also adjust machine settings as necessary to achieve the desired fabric finish.

4. Safety and Environmental Compliance

They strictly follow safety protocols, wearing protective gear and adhering to established safety procedures. They also ensure compliance with environmental regulations related to the singeing process, such as proper disposal of waste products.

5. Production Monitoring and Optimization

Singe Winders monitor production rates and identify areas for improvement. They make adjustments to machine settings, such as speed and temperature, to increase efficiency and reduce waste. They also participate in continuous improvement initiatives to optimize the singeing process.

Interview Tips

Preparing thoroughly for your interview can significantly increase your chances of success. Here are some tips to help you ace the interview for a Singe Winder position:

1. Research the Company and the Role

Before the interview, research the company’s history, mission, and products. Familiarize yourself with the specific responsibilities of the Singe Winder role and the company’s expectations. This will help you demonstrate your interest and understanding of the position.

2. Highlight Relevant Experience and Skills

Emphasize your experience in operating singeing machines and maintaining textile machinery. Showcase your skills in fabric preparation, quality control, and safety compliance. Quantify your accomplishments whenever possible, using specific examples and metrics to demonstrate your impact.

3. Practice Common Interview Questions

Anticipate common interview questions and prepare your responses in advance. Practice answering questions related to your technical skills, experience, and problem-solving abilities. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide detailed examples.

4. Prepare Industry-Specific Questions

Research industry-specific questions that demonstrate your knowledge of the textile industry and singeing processes. Ask thoughtful questions during the interview to show your engagement and interest in the field.

5. Dress Professionally and Arrive on Time

Dress appropriately for the interview, reflecting the professional nature of the position. Arrive on time or even slightly early to show respect for the interviewer’s schedule.

6. Be Enthusiastic and Positive

Throughout the interview, maintain a positive attitude and show enthusiasm for the role. Express your interest in working for the company and contribute to their success. Your positive demeanor and passion for the industry can make a lasting impression.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Singe Winder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.