Feeling lost in a sea of interview questions? Landed that dream interview for Single Needle Tufting Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Single Needle Tufting Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

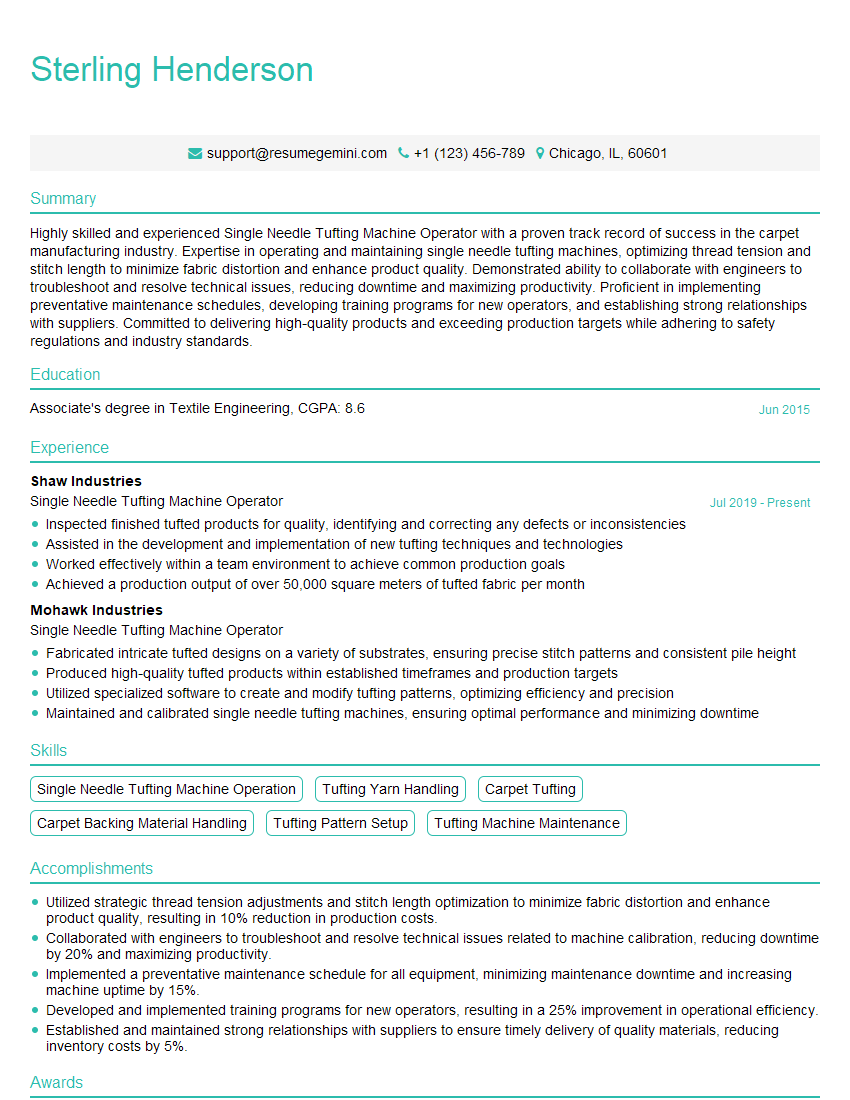

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Single Needle Tufting Machine Operator

1. Explain the process of setting up a single needle tufting machine?

To set up a single needle tufting machine, I follow these steps:

- Mount the fabric: I place the fabric on the machine’s backing and secure it with clamps.

- Thread the needle: I thread the yarn through the needle and tension it properly.

- Adjust machine settings: I adjust the machine’s speed, stitch length, and pile height based on the desired result.

- Test the machine: I run a test to ensure that the machine is functioning correctly and producing the desired stitch.

2. Describe the different types of yarn used in single needle tufting?

Cotton yarn

- Natural and absorbent

- Produces a soft and breathable tuft

Acrylic yarn

- Synthetic and durable

- Resistant to fading and pilling

Wool yarn

- Natural and insulating

- Creates a warm and cozy tuft

Polyester yarn

- Synthetic and wrinkle-resistant

- Produces a smooth and lustrous tuft

3. How do you troubleshoot common problems with a single needle tufting machine?

Here are some common troubleshooting tips for single needle tufting machines:

- Broken needle: Replace the needle with a new one of the same size and type.

- Yarn breakage: Check the yarn tension and adjust it if necessary. Also, inspect the yarn for any knots or damage.

- Uneven tufting: Ensure that the fabric is properly secured and that the machine’s settings are correct. Calibrate the machine if needed.

- Looping: Reduce the machine’s speed or increase the yarn tension. Check the needle for any burrs or damage.

4. How do you maintain a single needle tufting machine to ensure optimal performance?

To maintain a single needle tufting machine, I perform the following steps:

- Regular cleaning: Remove any lint, dust, or yarn scraps from the machine after each use.

- Needle replacement: Replace needles regularly to prevent breakage and ensure smooth operation.

- Lubrication: Lubricate the machine’s moving parts according to the manufacturer’s recommendations.

- Calibrations: Periodically calibrate the machine to ensure accurate stitch length and pile height.

5. What safety precautions should be taken when operating a single needle tufting machine?

When operating a single needle tufting machine, I prioritize the following safety precautions:

- Wear appropriate safety gear: This includes safety glasses, earplugs, and gloves.

- Keep work area clear: Remove any obstacles or loose materials that could cause tripping or entanglement.

- Secure the machine: Ensure that the machine is placed on a stable surface and is properly grounded.

- Inspect the machine before use: Check for any damaged parts or loose connections before operating the machine.

6. Can you describe the different techniques used in single needle tufting to create different designs?

There are several techniques used in single needle tufting to create unique designs:

- Linework: Creating continuous lines or outlines by following a pattern.

- Shading: Varying the stitch density to create gradients and depth.

- Carving: Cutting away tufted areas to reveal underlying layers or create intricate shapes.

- Looping and latch hooking: Creating decorative loops and shapes by manipulating the yarn.

7. How do you handle challenging fabrics or materials when using a single needle tufting machine?

When encountering challenging fabrics, I take these steps to ensure optimal results:

- Adjust machine settings: Modify the speed, stitch length, and pile height to accommodate the fabric’s texture and thickness.

- Use appropriate backing: Select a backing material that provides stability and support to the fabric.

- Test on a small area: Begin by testing the settings and techniques on a small portion of the fabric to avoid damaging the entire piece.

- Use a stabilizing agent: Apply a spray adhesive or backing fabric to stabilize delicate or stretchy fabrics.

8. What is your approach to creating custom designs using a single needle tufting machine?

To create custom designs, I follow this process:

- Sketch and plan: Develop a sketch or digital design to visualize the desired outcome.

- Choose yarn and fabric: Select materials that complement the design and the intended use of the piece.

- Set up the machine: Calibrate the machine and adjust settings based on the design and fabric.

- Tufted according to the design: Carefully follow the design, paying attention to stitch length, density, and color changes.

9. Describe a time when you faced a technical issue with a single needle tufting machine and how you resolved it?

During a recent project, I encountered a broken needle. I promptly replaced the needle, recalibrated the machine, and resumed tufting without any further issues. By having a spare needle on hand, I was able to resolve the problem quickly and minimize downtime.

10. How do you stay updated with the latest trends and techniques in single needle tufting?

To stay current with the latest trends and techniques, I engage in the following practices:

- Online forums and communities: Participate in online discussions and forums dedicated to single needle tufting.

- Social media platforms: Follow influencers and artisans on social media to see their work and learn about new techniques.

- Workshops and classes: Attend workshops or online courses to enhance my skills and knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Single Needle Tufting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Single Needle Tufting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Single Needle Tufting Machine Operators are responsible for operating, maintaining, and troubleshooting single needle tufting machines used in the production of carpets, rugs, and other tufted products. Key responsibilities include:

1. Machine Operation

Operate single needle tufting machines to produce tufted products according to specifications.

- Set up and adjust machines to produce desired patterns and textures.

- Monitor machine performance and make necessary adjustments to ensure efficient operation.

2. Yarn Management

Manage yarn supply and ensure continuous feeding into the machine.

- Inspect yarn for defects and ensure it meets quality standards.

- Monitor yarn tension and adjust as needed to prevent breaks and ensure uniform tufting.

3. Quality Control

Inspect finished products for defects and ensure they meet quality specifications.

- Identify and correct defects such as yarn breaks, uneven tufting, and color variations.

- Maintain records and report quality issues to supervisors.

4. Maintenance and Troubleshooting

Perform routine maintenance and troubleshooting on single needle tufting machines.

- Clean, lubricate, and adjust machines regularly to prevent breakdowns.

- Diagnose and resolve machine malfunctions to minimize downtime.

Interview Tips

To ace the interview for a Single Needle Tufting Machine Operator position, candidates should follow these tips:

1. Research the Company and Role

Research the company’s industry, products, and culture. Understand the specific responsibilities of the role and how they align with your skills and experience.

2. Highlight Relevant Skills and Experience

Emphasize your experience in operating single needle tufting machines, including any relevant certifications or training. Quantify your accomplishments whenever possible.

3. Prepare for Technical Questions

Anticipate technical questions about tufting machines, yarn management, and quality control. Practice answering these questions using specific examples from your work history.

4. Showcase Problem-Solving Abilities

Demonstrate your ability to troubleshoot and resolve machine malfunctions. Provide examples of how you identified and solved problems in a previous role.

5. Ask Informed Questions

Ask thoughtful questions during the interview to show your interest in the position and the company. This demonstrates your engagement and enthusiasm.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Single Needle Tufting Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!