Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Single Spindle Screw Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

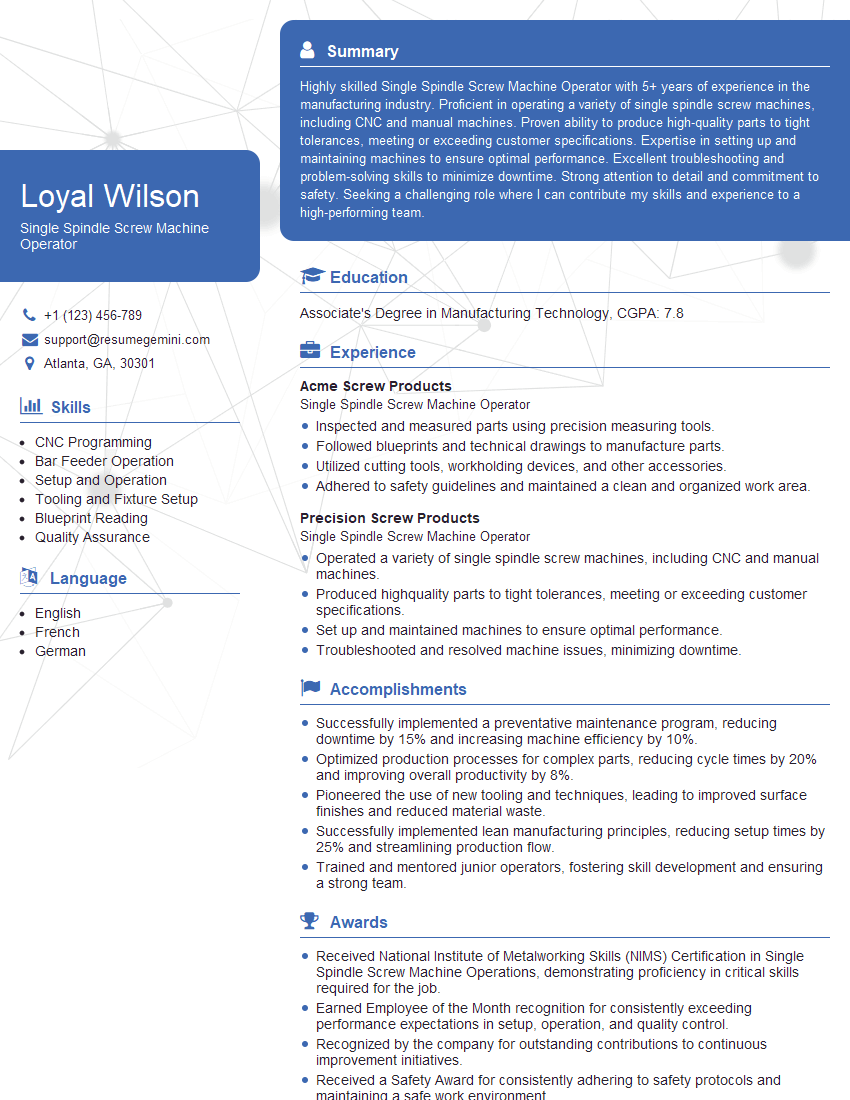

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Single Spindle Screw Machine Operator

1. What are the main components of a single spindle screw machine?

The main components of a single spindle screw machine include:

- Headstock

- Cross slide

- Tailstock

- Turrets

- Bar feed

- Spindle

- Chuck

- Coolant system

2. What are the different types of materials that can be machined on a single spindle screw machine?

Bar stock materials:

- Steel

- Stainless steel

- Brass

- Aluminum

- Copper

- Titanium

Forging materials:

- Steel

- Iron

3. What are the different types of operations that can be performed on a single spindle screw machine?

The different types of operations that can be performed on a single spindle screw machine include:

- Turning

- Drilling

- Boring

- Reaming

- Tapping

- Thread cutting

- Knurling

- Forming

4. What are the different types of tooling used on a single spindle screw machine?

The different types of tooling used on a single spindle screw machine include:

- Cutting tools

- Boring bars

- Drills

- Taps

- Dies

- Knurls

- Form tools

- Toolholders

5. What are the different types of controls used on a single spindle screw machine?

Manual controls:

- Handwheels

- Levers

Semi-automatic controls:

- Cam-operated

- Electrically-controlled

Computer numerical controls (CNC):

- Programmable

- Automated

6. What are the different types of safety devices used on a single spindle screw machine?

The different types of safety devices used on a single spindle screw machine include:

- Guards

- Interlocks

- Emergency stop buttons

7. What are the different types of maintenance tasks that are performed on a single spindle screw machine?

The different types of maintenance tasks that are performed on a single spindle screw machine include:

- Cleaning

- Lubrication

- Inspection

- Adjustment

- Repair

8. What are the different types of troubleshooting procedures that are used to diagnose problems with a single spindle screw machine?

The different types of troubleshooting procedures that are used to diagnose problems with a single spindle screw machine include:

- Visual inspection

- Listening for unusual noises

- Checking fluid levels

- Checking electrical connections

9. What are the different types of quality control procedures that are used to ensure the accuracy of parts produced on a single spindle screw machine?

The different types of quality control procedures that are used to ensure the accuracy of parts produced on a single spindle screw machine include:

- Dimensional inspection

- Surface finish inspection

- Hardness testing

- Material testing

10. What are the different types of training programs that are available for single spindle screw machine operators?

The different types of training programs that are available for single spindle screw machine operators include:

- On-the-job training

- Classroom training

- Online training

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Single Spindle Screw Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Single Spindle Screw Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Single Spindle Screw Machine Operators are responsible for the efficient operation of single spindle screw machines in order to produce complex and precision parts.

1. Machine Setup and Operation

An operator’s key responsibility is to set up, operate, and maintain single spindle screw machines. This involves performing tasks such as selecting and installing the appropriate tooling, loading and unloading raw materials, and adjusting machine settings to ensure optimal performance. They must also monitor the machine’s operation, making adjustments as needed to maintain accuracy and prevent defects.

- Sets up and operates single spindle screw machines to produce complex and precision parts.

- Selects and installs the appropriate tooling for the job.

- Loads and unloads raw materials.

- Adjusts machine settings to ensure optimal performance.

- Monitors the machine’s operation and makes adjustments as needed to maintain accuracy and prevent defects.

2. Quality Assurance

Operators are also responsible for ensuring that the parts produced meet the required specifications. They visually inspect parts for defects, measure parts using precision measuring instruments, and make adjustments to the machine as needed to ensure that parts meet tolerance requirements.

- Visually inspects parts for defects.

- Measures parts using precision measuring instruments.

- Makes adjustments to the machine as needed to ensure that parts meet tolerance requirements.

3. Maintenance and Repair

Operators are responsible for performing basic maintenance and repair tasks on their machines. They lubricate and clean the machine, replace worn or damaged parts, and troubleshoot and resolve minor problems. This helps to prevent breakdowns and ensures that the machine is operating at peak efficiency.

- Lubricates and cleans the machine.

- Replaces worn or damaged parts.

- Troubleshoots and resolves minor problems.

4. Production Reporting

Operators are responsible for maintaining production records and reporting any problems or issues to their supervisor. This information is used to track progress, identify areas for improvement, and ensure that the machine is operating at peak efficiency.

- Maintains production records.

- Reports any problems or issues to their supervisor.

Interview Tips

To ace the interview, candidates should prepare thoroughly and present themselves professionally.

1. Research the Company and Position

Take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, their products or services, and the key responsibilities of the role. Understanding the company’s goals and values will also help you tailor your answers to the interviewer’s questions.

- Visit the company’s website.

- Read industry news and articles.

- Talk to people in your network who work in the industry.

2. Practice Your Answers

Once you have a good understanding of the company and the position, practice answering common interview questions. This will help you feel more confident and prepared during the interview. Consider using the STAR method to structure your answers (Situation, Task, Action, Result). The STAR method helps you provide clear and concise examples of your skills and experience.

- Use the STAR method to answer interview questions.

- Practice answering questions with a friend or family member.

- Record yourself answering questions and watch it back to identify areas for improvement.

3. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally for the interview and arrive on time. This shows the interviewer that you are serious about the position and that you respect their time.

- Dress in business attire.

- Arrive on time for the interview.

4. Be Enthusiastic and Positive

Interviewers are looking for candidates who are enthusiastic about the position and who have a positive attitude. Be yourself, but be sure to show the interviewer that you are excited about the opportunity to work for their company.

- Be yourself.

- Show the interviewer that you are excited about the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Single Spindle Screw Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!