Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Single Spindle Screw Machine Set-Up Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

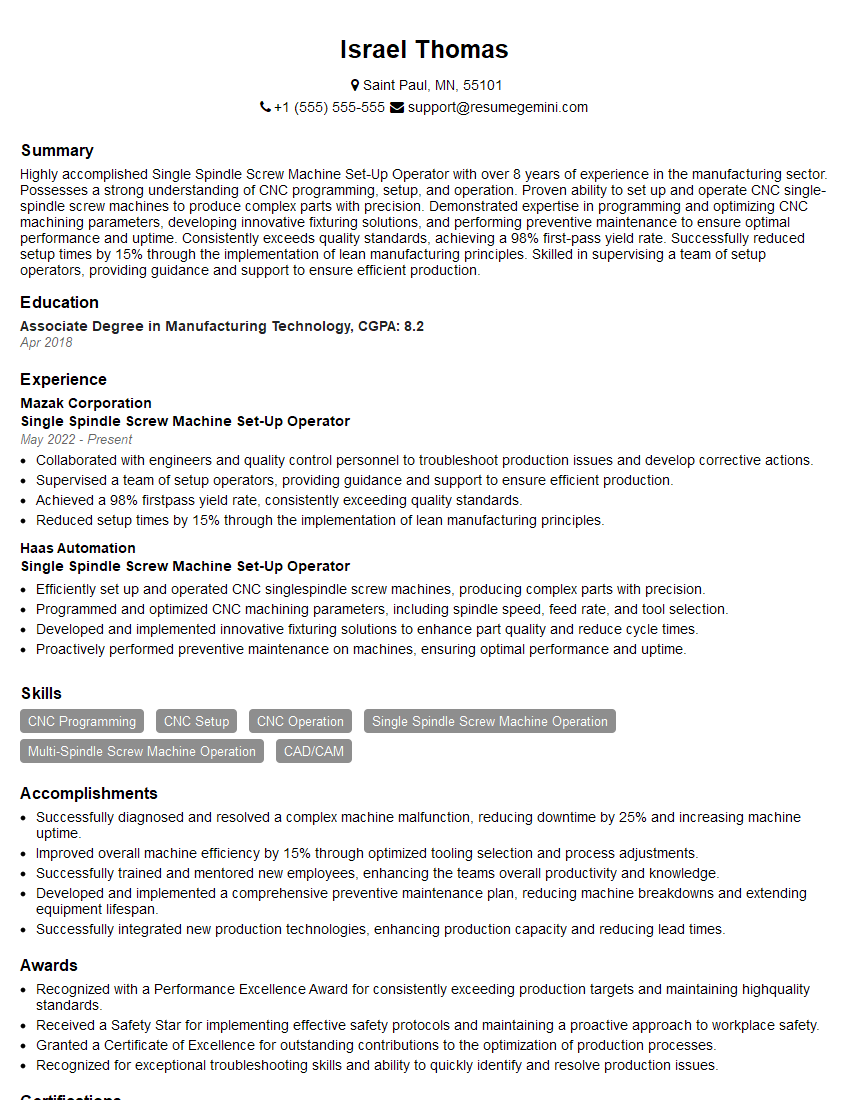

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Single Spindle Screw Machine Set-Up Operator

1. What are the key responsibilities of a Single Spindle Screw Machine Set-Up Operator?

- Set up and operate single spindle screw machines to produce precision parts.

- Interpret blueprints and specifications to determine machine settings and tooling requirements.

- Select and install appropriate tooling, including cutting tools, collets, and fixtures.

- Adjust machine settings, such as spindle speed, feed rate, and coolant flow.

- Monitor machine operation and make adjustments as needed to ensure quality and productivity.

- Inspect finished parts to ensure they meet specifications.

- Maintain and troubleshoot machines to prevent downtime.

- Follow safety procedures and wear appropriate personal protective equipment.

2. How do you ensure that the parts produced on the single spindle screw machine meet the required specifications?

subheading of the answer

- By carefully interpreting the blueprints and specifications to determine the required dimensions, tolerances, and finishes.

- By selecting and installing the appropriate tooling, including cutting tools, collets, and fixtures.

- By adjusting machine settings, such as spindle speed, feed rate, and coolant flow, to optimize cutting conditions.

- By monitoring machine operation and making adjustments as needed to ensure that the parts are being produced to the correct specifications.

- By inspecting finished parts to ensure that they meet all of the required specifications.

subheading of the answer

- By following established quality control procedures.

- By using precision measuring tools and gauges.

- By working closely with quality control personnel to identify and correct any problems with the parts or the machining process.

3. What are the different types of tooling used on a single spindle screw machine?

- Cutting tools, such as drills, taps, reamers, and end mills.

- Collets, which hold the workpiece in place.

- Fixtures, which are used to support and guide the workpiece during machining.

- Tool holders, which are used to mount cutting tools to the machine.

- Lubricants and coolants, which are used to reduce friction and heat during machining.

4. How do you troubleshoot common problems that occur on a single spindle screw machine?

- By identifying the symptoms of the problem.

- By checking the machine settings and tooling to ensure that they are correct.

- By inspecting the workpiece to identify any defects.

- By consulting with other operators or supervisors to get their input.

- By referring to the machine’s maintenance manual.

- By calling the machine manufacturer for technical support.

5. What are the safety precautions that must be taken when operating a single spindle screw machine?

- Wear appropriate personal protective equipment, such as safety glasses, earplugs, and gloves.

- Keep the work area clean and free of debris.

- Inspect the machine before each use to ensure that it is in good working order.

- Follow all of the manufacturer’s instructions for operating the machine.

- Never reach into the machine while it is running.

- Be aware of the location of the emergency stop button.

- Never operate the machine if you are tired or under the influence of drugs or alcohol.

6. What is the importance of preventive maintenance for single spindle screw machines?

- By preventing unexpected breakdowns.

- By extending the life of the machine.

- By reducing the need for costly repairs.

- By improving the quality of the parts produced.

- By increasing productivity.

7. What are the different types of preventive maintenance tasks that should be performed on a single spindle screw machine?

- Cleaning and lubricating the machine.

- Inspecting the machine for wear and tear.

- Tightening loose bolts and screws.

- Replacing worn or damaged parts.

- Calibrating the machine.

8. What are the benefits of using CNC (computer numerical control) on a single spindle screw machine?

- Increased accuracy and repeatability.

- Faster production speeds.

- Reduced setup times.

- Improved quality of the parts produced.

- Reduced labor costs.

- Increased flexibility.

9. What are the different types of materials that can be machined on a single spindle screw machine?

- Metals, such as steel, aluminum, and brass.

- Plastics, such as nylon, polyethylene, and polypropylene.

- Wood.

- Composites.

10. What are the career advancement opportunities for a Single Spindle Screw Machine Set-Up Operator?

- Machine operator.

- CNC programmer.

- Setup supervisor.

- Production supervisor.

- Maintenance technician.

- Quality control inspector.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Single Spindle Screw Machine Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Single Spindle Screw Machine Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Single Spindle Screw Machine Set-Up Operator is responsible for setting up and operating a single spindle screw machine, ensuring that it produces high-quality parts according to specifications.

1. Machine Set-Up

Set up and maintain single spindle screw machines according to engineering specifications.

- Install and adjust tooling, fixtures, and workholding devices.

- Verify machine settings and calibrate measurement devices.

2. Production Operation

Operate single spindle screw machines efficiently to produce parts.

- Load and unload raw materials and finished parts.

- Monitor machine operation and make adjustments as needed.

3. Quality Control

Inspect parts produced by the machine to ensure they meet specifications.

- Inspect parts for dimensions, tolerances, and surface finish.

- Identify and correct any defects or deviations.

4. Maintenance and Troubleshooting

Perform basic maintenance and troubleshooting tasks on single spindle screw machines.

- Lubricate and clean machines.

- Diagnose and resolve common machine problems.

Interview Tips

In preparing for an interview for a Single Spindle Screw Machine Set-Up Operator position, it is important to highlight your technical skills, attention to detail, and problem-solving abilities.

1. Research the Company and Position

Familiarize yourself with the company’s products, operations, and culture. Understand the specific responsibilities and requirements of the Single Spindle Screw Machine Set-Up Operator position.

- Visit the company’s website and social media pages.

- Review industry publications and articles to gain insights into the company and its competitors.

2. Practice Common Interview Questions

Prepare for common interview questions related to your technical skills and experience. Practice answering questions about machine set-up, production operation, quality control, maintenance, and troubleshooting.

- Describe your experience with setting up and operating a single spindle screw machine.

- Explain how you ensure the quality of parts produced on a screw machine.

- Provide examples of common machine problems you have encountered and how you resolved them.

3. Showcase Your Skills and Experience

Highlight your technical skills, such as your knowledge of machine tools, tooling, and measurement devices. Emphasize your attention to detail and your ability to identify and correct defects.

- Quantify your accomplishments whenever possible. For example, instead of saying “I set up and operated screw machines,” you could say “I set up and operated screw machines, resulting in a 15% reduction in downtime.”

- Provide specific examples of your experience and skills. For instance, instead of saying “I troubleshoot machine problems,” you could say “I diagnosed and resolved a critical machine problem that resulted in a 3-hour increase in production time.”

4. Dress Professionally and Be Punctual

First impressions matter. Dress professionally and arrive for your interview on time. Show the interviewer that you are serious about the position and respect their time.

- Wear clean and pressed clothing.

- Make sure your shoes are polished.

- Arrive for your interview a few minutes early.

Next Step:

Now that you’re armed with the knowledge of Single Spindle Screw Machine Set-Up Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Single Spindle Screw Machine Set-Up Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini