Are you gearing up for a career in Sinker Winder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Sinker Winder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

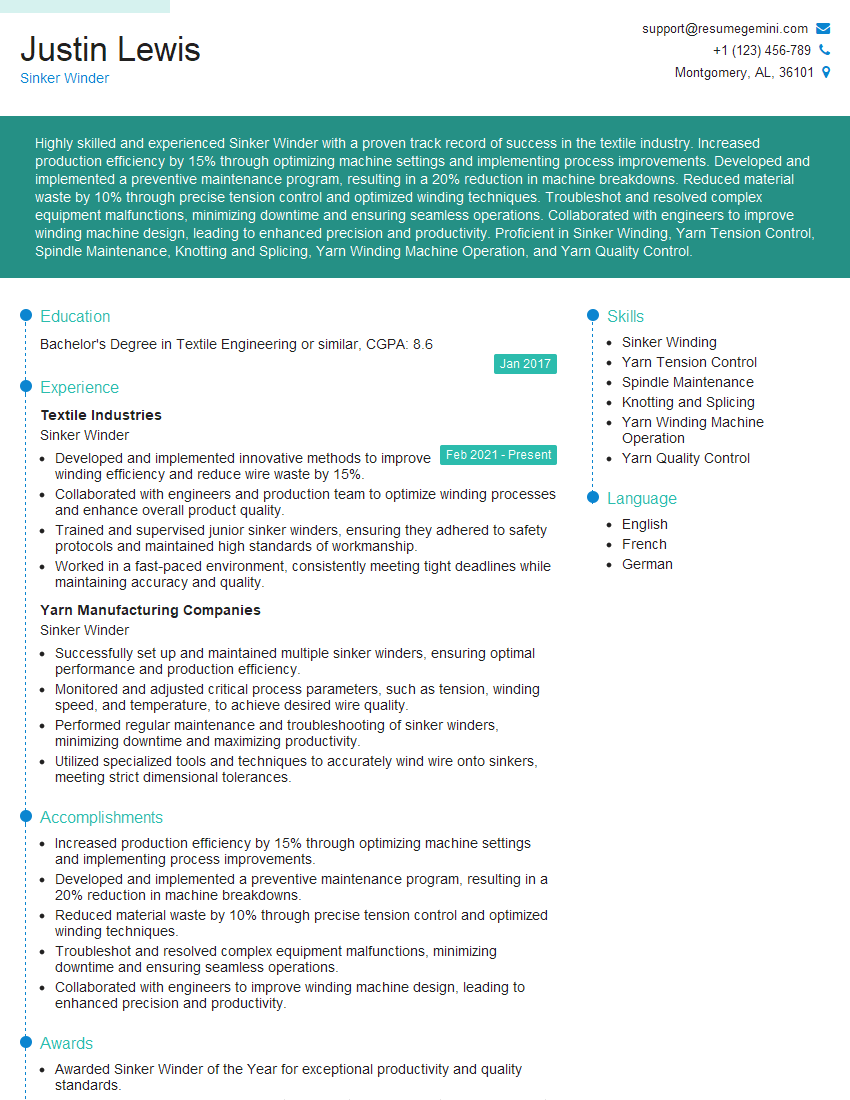

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sinker Winder

1. What are the different types of winding machines used in sinker winding?

- Double-twisting machine

- Cone winding machine

- Spool winding machine

2. What is the purpose of tension control in sinker winding?

- To maintain consistent yarn tension throughout the winding process

- To prevent yarn breakage and ensure uniform winding quality

3. How do you adjust the winding tension on a cone winding machine?

- Adjust the brake tension

- Calibrate the tensioner

- Use a tension meter to monitor tension levels

4. What are the common defects in sinker winding?

- Yarn breakage

- Uneven winding

- Loose or tight winding

- Contamination or foreign objects in the yarn

5. How do you troubleshoot and resolve winding defects?

- Identify the source of the defect

- Check machine settings and adjust accordingly

- Inspect yarn quality and replace if necessary

- Clean and maintain winding machines regularly

6. What are the safety precautions to observe when operating a sinker winding machine?

- Wear appropriate safety gear

- Keep loose clothing and jewelry away from moving parts

- Be aware of potential hazards and take precautions

- Follow proper machine operating procedures

7. How do you calculate the winding speed for a given yarn count and package size?

- Use the winding speed formula

- Consider yarn linear density and package diameter

- Adjust speed based on machine capabilities and yarn characteristics

8. What are the different types of yarn packages produced by sinker winding?

- Cones

- Spools

- Cheeses

- Pirns

9. How do you ensure the quality of sinker-wound yarn?

- Inspect yarn for defects before winding

- Monitor winding parameters and make adjustments as needed

- Perform regular quality checks on yarn packages

- Follow established quality control procedures

10. What is your experience in optimizing winding processes to improve efficiency and reduce waste?

- Analyzed winding machine parameters and identified areas for improvement

- Implemented changes to winding tension, speed, and yarn handling

- Reduced yarn breakage and machine downtime

- Increased production efficiency and overall yarn quality

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sinker Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sinker Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Sinker Winder, you will have the primary responsibility of operating and overseeing the winding of sinkers used in fishing nets and other applications.

1. Machine Operation and Maintenance

Your core duty involves effectively handling and maintaining sinker winding machines. This includes:

- Setting up and adjusting machine parameters to ensure optimal winding processes.

- Monitoring machine operations during production to identify and address any potential issues or malfunctions.

- Performing routine maintenance and cleaning tasks to preserve machine functionality and longevity.

2. Sinker Winding

You will be responsible for the actual winding of sinkers, ensuring they meet quality standards. This entails:

- Loading and unloading sinkers onto the winding machine according to production schedules.

- Adjusting winding tension and speed to produce sinkers with consistent dimensions and weights.

- Inspecting wound sinkers for defects or irregularities, and segregating or re-winding as necessary.

3. Material Handling

Efficient material handling is crucial for smooth production flow. Your tasks include:

- Receiving and storing raw materials, including sinkers and winding wire.

- Transporting materials to and from winding machines using appropriate handling equipment.

- Maintaining a clean and organized work area to prevent accidents and ensure efficiency.

4. Quality Control

Ensuring the quality of wound sinkers is of utmost importance. You will:

- Conduct periodic quality checks on wound sinkers to verify adherence to specifications.

- Identify and resolve any quality issues or deviations from standards.

- Maintain detailed records of quality control checks for traceability and documentation purposes.

Interview Preparation Tips

To ace your interview for a Sinker Winder position, consider the following tips:

1. Research the Company and Industry

Take the time to thoroughly research the company you’re applying to and the fishing net industry in general. This will demonstrate your interest and preparedness.

- Visit the company website to learn about their history, products, and values.

- Read industry news and articles to stay informed about current trends and best practices.

2. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers. Anticipate questions related to your skills, experience, and knowledge of the industry.

- “Tell me about your experience operating sinker winding machines.”

- “How do you ensure the quality of wound sinkers?”

3. Highlight Relevant Skills and Experience

Emphasize your proficiency in the key responsibilities of a Sinker Winder. Use specific examples from your previous work experience to demonstrate your abilities.

- Describe how you successfully maintained and repaired winding machines.

- Provide examples of your attention to detail and commitment to quality control.

4. Be Enthusiastic and Engage with the Interviewer

Convey your enthusiasm for the position and industry. Show the interviewer that you’re genuinely interested in the role and eager to contribute your skills.

- Ask thoughtful questions to demonstrate your engagement and curiosity.

- Express your passion for working with machinery and producing quality products.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sinker Winder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!