Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sinter Feeder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

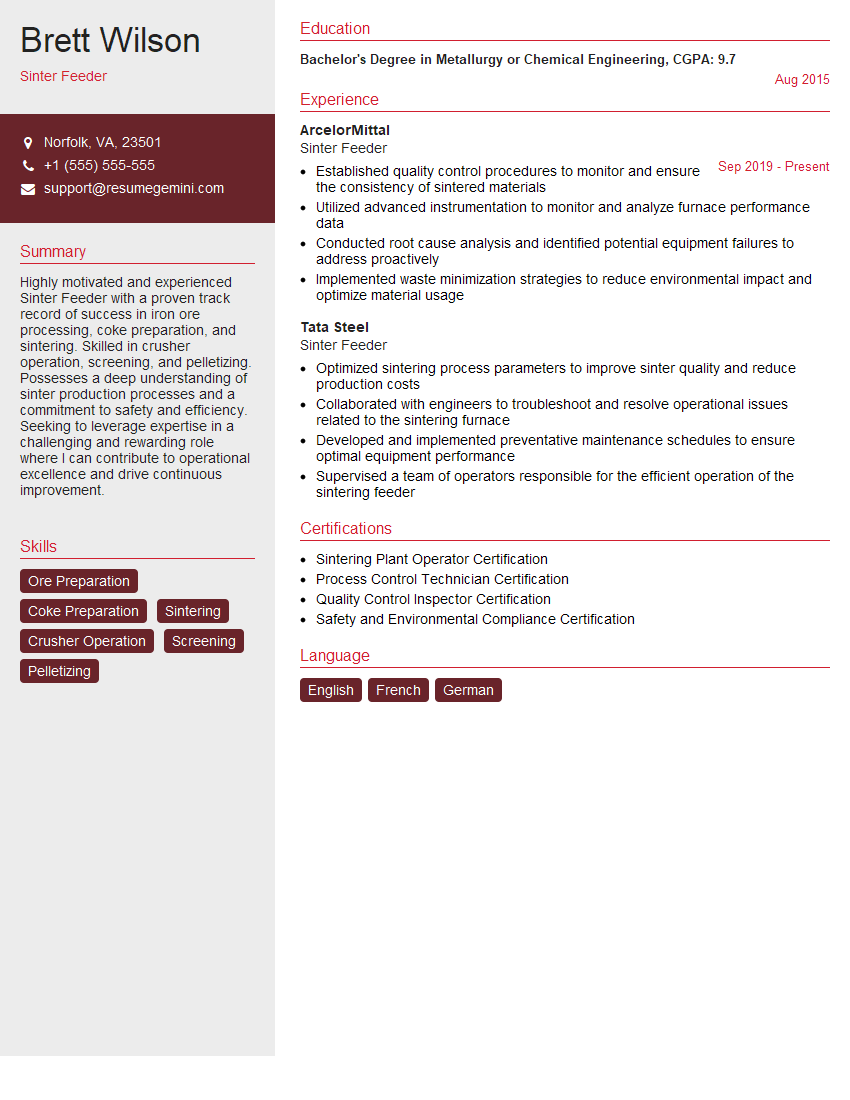

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sinter Feeder

1. Explain the working principle of a Sinter Feeder.

A Sinter Feeder is an essential component of the Sintering Plant, used to uniformly feed prepared mix onto the Sintering Machine’s endless grate. The Feeder comprises two main sections:

- Vibration Hopper: It is a conical hopper that rests on a vibrating frame. The vibration ensures the uniform flow of the Sinter mix into the distribution chute.

- Distribution Chute: This chute has multiple outlets to evenly distribute the mix onto the grate’s total width.

2. What are the key design considerations for a Sinter Feeder?

Flow Rate Control: The feeder should maintain the desired material flow rate onto the grate to ensure optimal sintering and avoid blockages.

Distribution Uniformity: The feeder must ensure uniform distribution of the mix across the grate’s width to create a consistent and stable sinter bed.

Mix Condition: The feeder should handle and convey the mix without segregation or degradation to maintain its properties and ensure efficient sintering.

3. Describe the maintenance procedures for a Sinter Feeder.

Regular Inspections: Daily visual inspections and vibration monitoring to identify any abnormalities or damage.

Cleaning and Lubrication: Clean the feeder regularly to remove any material buildup or debris. Lubricate moving parts as per the manufacturer’s recommendations.

Component Check: Periodically inspect and test the vibrating frame, chute, and control system to ensure proper operation.

Calibration: Calibrate the feeder regularly to maintain the desired flow rate and distribution pattern.

4. How do you troubleshoot a Sinter Feeder with uneven mix distribution?

Check Material Flow: Ensure that the Sinter mix is flowing smoothly from the hopper and that there are no blockages.

Inspect Discharge Chute Outlets: Check if the outlets are clear and distributing the mix evenly. Adjust or replace any damaged outlets.

Examine Feeder Vibration: Verify that the feeder is vibrating evenly and generating the necessary force for consistent distribution.

5. What are the safety precautions to be followed when operating a Sinter Feeder?

Personal Protective Equipment: Always wear appropriate PPE, including safety glasses, gloves, and earplugs.

Guarding: Ensure that all moving parts and electrical components are properly guarded to prevent contact.

Lockout/Tagout: Follow established procedures for lockout/tagout before performing any maintenance or repairs.

Area Access: Restrict access to the feeder area during operation to prevent unauthorized personnel from coming into contact with the machine.

6. Explain how the flow rate of the Sinter mix is controlled in a Sinter Feeder.

Adjustable Gate: A gate at the bottom of the hopper can be adjusted to regulate the mix flow rate by increasing or decreasing the opening.

Vibration Frequency: Varying the vibration frequency of the feeder can impact the flow rate. Higher frequencies generally result in increased flow.

Material Properties: The flow rate can be influenced by the characteristics of the Sinter mix, such as moisture content and particle size distribution.

7. What are the advantages of using a Sinter Feeder in a Sintering Plant?

- Uniform and consistent material distribution on the grate

- Improved bed permeability, leading to optimal air and gas flow during sintering

- Reduced risk of blockages and uneven sintering

- Increased productivity and efficiency of the Sintering process

8. How would you optimize the performance of a Sinter Feeder for improved Sinter quality?

Fine-Tune Flow Rate: Adjust the flow rate to match the specific requirements of the Sintering process and material characteristics.

Ensure Uniform Distribution: Check and calibrate the feeder regularly to maintain even distribution across the grate’s width.

Minimize Segregation: Prevent the segregation of different materials within the mix by controlling the vibration and flow rate.

9. Describe the instrumentation used in a Sinter Feeder.

- Flow Rate Sensor: Measures the amount of mix flowing through the feeder.

- Vibration Sensor: Monitors the vibration frequency and amplitude of the feeder.

- Temperature Sensors: Check the temperature of various components to prevent overheating.

- Control System: Regulates the feeder’s operation based on sensor inputs and operator commands.

10. How do you ensure the longevity and reliability of a Sinter Feeder?

Regular Maintenance: Adhere to recommended maintenance schedules for cleaning, lubrication, and component inspections.

Proper Operation: Follow operating procedures to avoid overloading or improper use of the feeder.

Use of Quality Components: Select durable and high-quality components for the feeder, especially wear-resistant materials.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sinter Feeder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sinter Feeder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Sinter Feeder plays a crucial role in the iron and steel industry by operating and maintaining equipment used to prepare and feed sinter materials into a blast furnace. Their primary tasks include:

1. Equipment Operation

Operate and maintain conveyors, screens, bunkers, and other equipment involved in the sintering process.

- Monitor equipment performance and ensure smooth operation.

- Identify and troubleshoot equipment malfunctions promptly.

2. Material Preparation

Prepare and blend raw materials, such as iron ore, coke, and limestone, to create a uniform sinter mix.

- Control material flow and adjust blending ratios as per specifications.

- Ensure the quality and consistency of the sinter mix.

3. Sinter Feeding

Operate feeders to deliver the sinter mix into the blast furnace.

- Monitor and adjust the feed rate to maintain optimal blast furnace operation.

- Prevent blockages or interruptions in the sinter feeding process.

4. Quality Control

Test and monitor the quality of sinter materials and products.

- Conduct regular inspections and tests to ensure compliance with specifications.

- Document and report quality control data and findings.

Interview Tips

Preparing thoroughly for a Sinter Feeder interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s profile, their products or services, and the specific requirements of the Sinter Feeder role. Understanding the industry trends and best practices will also demonstrate your interest and knowledge.

- Visit the company’s website and explore relevant industry publications.

- Network with professionals in the field to gain insights.

2. Practice Answering Common Interview Questions

Anticipate common interview questions related to your technical skills, experience, and problem-solving abilities. Prepare thoughtful and concise answers that highlight your strengths and how they align with the job requirements.

- Review job descriptions and identify key responsibilities.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

3. Showcase Your Technical Expertise

Emphasize your technical knowledge and skills in operating and maintaining sintering equipment. Discuss your experience in material preparation, sinter feeding, and quality control. Quantify your accomplishments with specific examples and data whenever possible.

- Highlight any certifications or training you have in related areas.

- Describe projects or initiatives where you improved efficiency or resolved technical issues.

4. Prepare Questions for the Interviewer

Asking thoughtful questions demonstrates your engagement and interest in the position. Prepare questions that focus on the specific responsibilities of the Sinter Feeder, the company’s operations, and any potential growth opportunities.

- Inquire about the company’s environmental initiatives related to the sintering process.

- Ask about the opportunities for professional development and career advancement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sinter Feeder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!