Are you gearing up for a career in Six Color Press Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Six Color Press Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

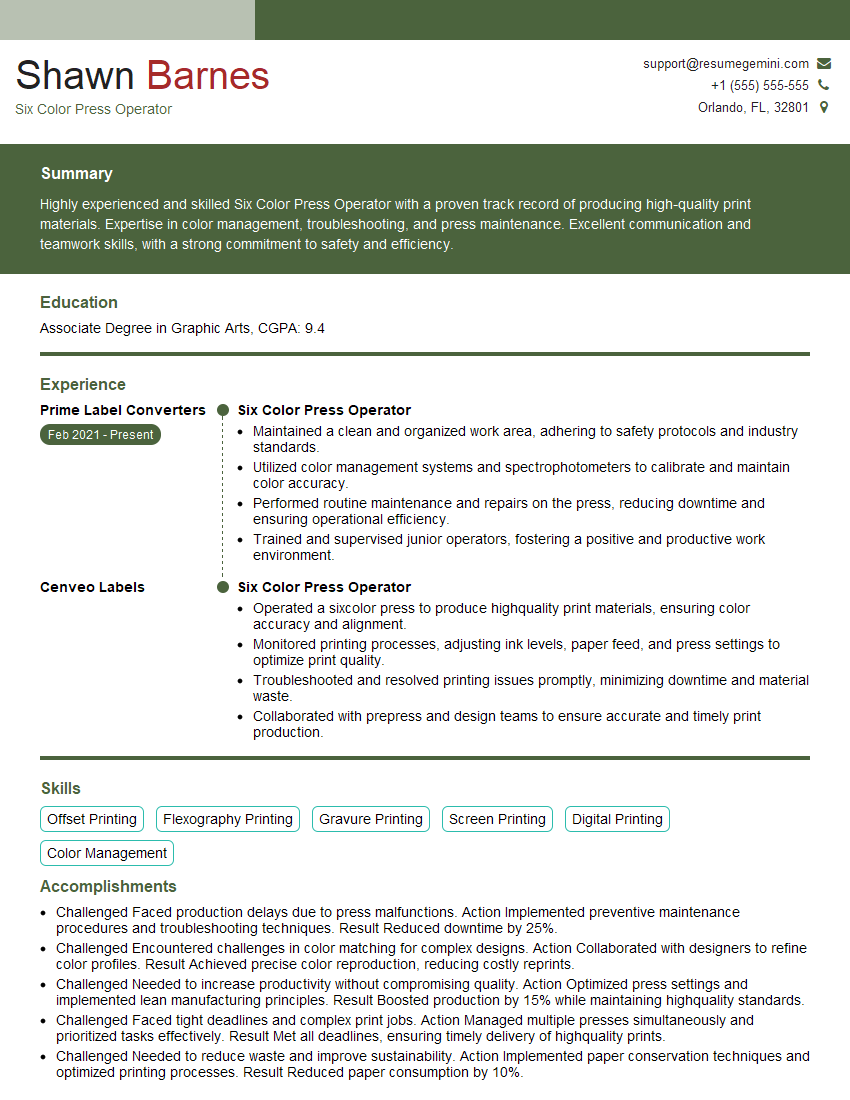

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Six Color Press Operator

1. Explain the process of calibrating a six-color press.

The process of calibrating a six-color press involves several key steps:

- Establish a baseline: Determine the current color values of the press using a densitometer.

- Create a target profile: Define the desired color values based on industry standards or customer specifications.

- Adjust ink densities: Modify the ink flow to match the target color values by adjusting the ink keys and dampening system.

- Proof and verify: Print test proofs and use a spectrophotometer to measure and compare the color values to the target profile.

- Make fine-tuning adjustments: If necessary, make small incremental adjustments to the ink densities and press settings to achieve optimal color accuracy.

2. How do you troubleshoot color registration issues on a six-color press?

- Inspect the press: Check for any loose or misaligned components, such as rollers, belts, or plates.

- Verify plate alignment: Ensure that the printing plates are properly mounted and aligned on the press cylinders.

- Adjust the feeder and delivery systems: Calibrate the paper feed and delivery mechanisms to minimize skewing or shifting of the paper during printing.

- Optimize ink-water balance: Adjust the ink flow and dampening system to ensure proper ink transfer and minimize slurring or ghosting.

- Check press speed: Slowing down the press speed can improve registration accuracy, especially for complex designs.

3. What is the importance of maintaining proper ink-water balance on a six-color press?

Maintaining proper ink-water balance on a six-color press is crucial for achieving optimal print quality:

- Color accuracy: The correct balance ensures that the ink is transferred consistently to the paper, resulting in accurate color reproduction.

- Image clarity: Balanced ink and water levels prevent waterlogging or ink piling, leading to sharp and clear images.

- Press stability: Proper ink-water balance reduces fluctuations in the printing process, ensuring consistent print quality over long runs.

- Machine longevity: Maintaining the correct balance minimizes wear and tear on the press components, extending its lifespan.

4. How do you determine the correct amount of pressure to apply during printing on a six-color press?

- Paper type: Different paper stocks require varying amounts of pressure to ensure proper ink transfer.

- Ink viscosity: Thicker inks require higher pressure to be effectively transferred to the paper.

- Press speed: Higher press speeds demand increased pressure to maintain ink adhesion.

- Plate quality: Worn or damaged plates may require higher pressure to compensate for reduced ink transfer.

- Empirical testing: Conduct test prints with different pressure settings to determine the optimal pressure that yields the desired print quality.

5. Describe the different types of drying systems used in six-color presses and their applications.

Infrared drying

- Uses infrared radiation to evaporate solvents and dry the ink quickly.

- Suitable for high-speed printing and web presses.

Ultraviolet curing

- Employs ultraviolet light to cure the ink through a chemical reaction.

- Provides instant curing, allowing for immediate post-press processes.

Hot air drying

- Uses hot air to evaporate solvents and dry the ink gradually.

- Suitable for thicker inks and substrates that are sensitive to heat.

Electron beam curing

- Accelerates electrons to high energy levels and directs them at the printed ink.

- Provides rapid curing and excellent adhesion for specialized applications.

6. Explain the principles of color theory and how they apply to six-color printing.

- Primary colors: Cyan, magenta, and yellow are the primary colors used in six-color printing.

- Secondary colors: Mixing primary colors produces secondary colors (green, orange, violet).

- Tertiary colors: Combining primary and secondary colors creates tertiary colors.

- Additive color mixing: Used in digital displays, where light is combined to create colors.

- Subtractive color mixing: Used in printing, where inks absorb and reflect light to create colors.

7. Describe the importance of proper waste management in a six-color press environment.

- Environmental compliance: Meeting regulatory requirements for disposal of hazardous materials (e.g., inks, solvents).

- Health and safety: Minimizing exposure to hazardous chemicals for employees and the environment.

- Cost savings: Reducing waste disposal costs through proper recycling and waste reduction programs.

- Sustainability: Preserving natural resources and reducing the environmental impact of printing operations.

8. How do you maintain the accuracy and precision of a six-color press over extended printing runs?

- Regular calibration: Periodically calibrate the press to ensure color accuracy and registration.

- Plate inspection: Regularly inspect printing plates for wear or damage that could affect print quality.

- Ink and water control: Monitor and adjust ink and water levels to maintain proper ink-water balance.

- Press monitoring: Regularly inspect the press for any signs of wear or malfunction that could impact print quality.

- Preventive maintenance: Follow manufacturer’s recommendations for regular maintenance and cleaning of the press.

9. Explain the different types of paper stocks used in six-color printing and their suitability for various applications.

- Uncoated paper: Absorbent and provides a natural finish, ideal for writing and printing text.

- Coated paper: Has a smooth, glossy finish that enhances color reproduction, suitable for high-quality prints.

- Textured paper: Adds tactile and visual interest, often used for specialty applications like invitations or greeting cards.

- Specialty paper: Includes papers with unique properties, such as waterproof or synthetic materials, catering to specific printing needs.

10. Discuss the challenges and opportunities in the field of six-color printing.

Challenges:

- Color accuracy and consistency: Maintaining precise color reproduction across multiple print runs.

- Substrate compatibility: Ensuring proper ink adhesion and print quality on different paper stocks.

- Environmental regulations: Adhering to strict environmental regulations for waste disposal and emissions.

- Technological advancements: Keeping up with rapid technological changes in printing equipment and techniques.

Opportunities:

- High-quality printing: Six-color printing enables exceptional color reproduction and print quality.

- Wide range of applications: Suitable for a variety of printing applications, from commercial brochures to packaging.

- Growing demand: As businesses recognize the impact of high-quality printing, the demand for six-color printing services is increasing.

- Career advancement: Skilled six-color press operators are in high demand in the printing industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Six Color Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Six Color Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Six Color Press Operator is responsible for the operation, maintenance, and repair of a six-color printing press. This individual must have a thorough understanding of the printing process, as well as the ability to operate and maintain the equipment.

1. Manage Press Operations

Prepare the press for printing, including loading paper, setting up ink, and adjusting printing plates.

- Continuously monitor the printing process to ensure that the press is running smoothly and that the print quality meets specifications.

- Make adjustments to the press as needed to maintain print quality and efficiency.

2. Maintain and Repair Equipment

Perform routine maintenance on the press, including cleaning, lubrication, and minor repairs.

- Troubleshoot and repair complex press problems.

- Order and install replacement parts as needed.

3. Ensure Print Quality

Inspect printed materials to ensure that they meet quality standards.

- Calibrate the press to ensure that colors are accurate and consistent.

- Make adjustments to the press as needed to correct color problems.

4. Safety Compliance

Follow all safety regulations and procedures.

- Wear appropriate safety gear, such as gloves and safety glasses.

- Keep the work area clean and free of hazards.

Interview Tips

Preparing for an interview for a Six Color Press Operator position requires research on the company, the position, and the industry. Additionally, practicing answers to common interview questions and preparing questions for the interviewer can increase your chances of success.

1. Research the Company and Industry

Visit the company’s website to learn about their business, products or services, and culture.

- Research the printing industry to understand the latest trends and technologies.

- Identify the company’s competitors and their strengths and weaknesses.

2. Practice Interview Answers

Prepare answers to common interview questions, such as:

- Tell me about your experience operating a six-color press.

- What are some of the challenges you’ve faced as a press operator?

- How do you ensure that printed materials meet quality standards?

- What are your strengths and weaknesses as a press operator?

3. Prepare Questions for the Interviewer

Asking thoughtful questions shows that you’re engaged and interested in the position.

- What are the company’s growth plans for the future?

- What are the biggest challenges facing the printing industry today?

- What are the opportunities for advancement within the company?

- What is the company culture like?

4. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for your interview.

- A suit or business casual attire is appropriate for most interviews.

- Be punctual and arrive at the interview location at least 15 minutes early.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Six Color Press Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.