Are you gearing up for an interview for a Sizing Machine Tender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Sizing Machine Tender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

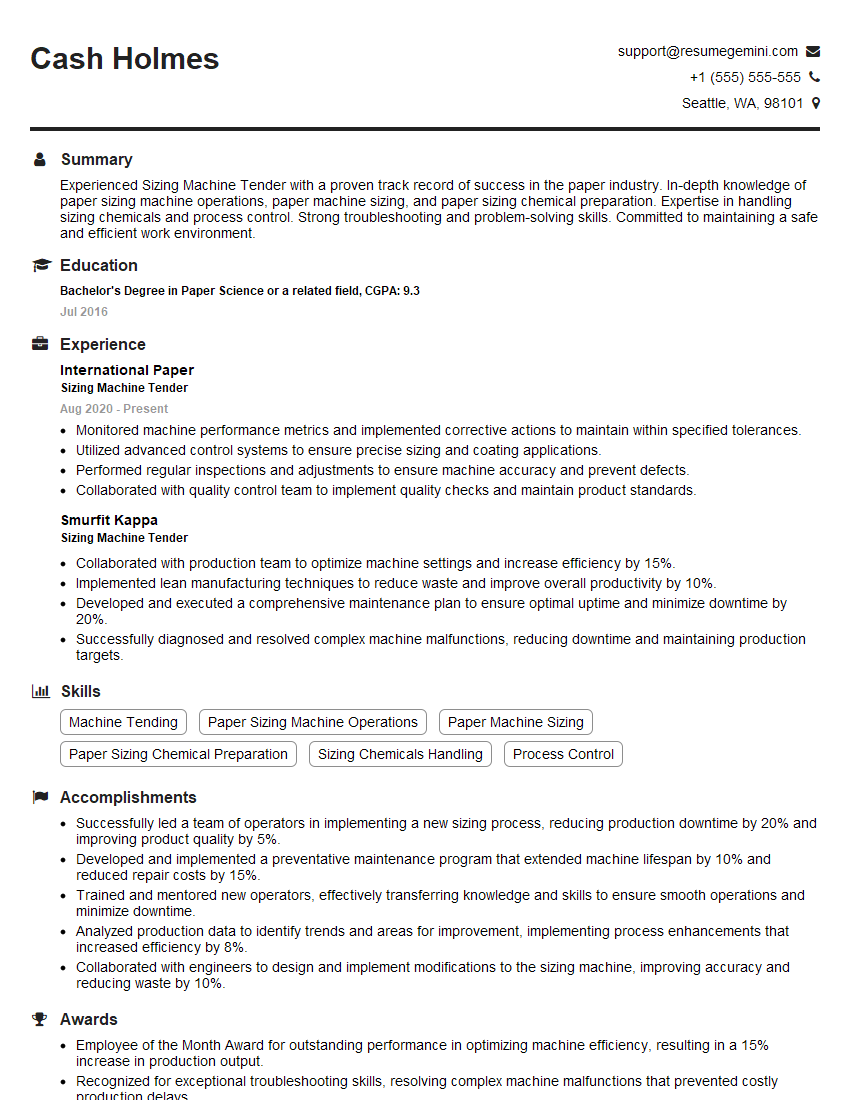

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sizing Machine Tender

1. Explain the sizing machine’s components and their functions?

Components of a Sizing Machine:

- Creel: Holds the warp yarns.

- Beaming Machine: Winds the warp yarns onto the beam.

- Drying Oven: Removes moisture from the yarns.

- Sizing Box: Applies sizing agent to the yarns.

- Drying Cylinder: Dries the sized yarns, and removes residual sizing agent.

- Winder: Winds the sized yarns onto a package (e.g., cone or bobbin).

Functions of the Sizing Machine Components:

- Unwind and tension the warp yarns.

- Apply sizing agent evenly to the yarns.

- Dry and cure the sizing agent.

- Wind the sized yarns onto a package for further processing.

2. Describe the process of preparing a sizing solution?

Calculating Sizing Agent Concentration:

- Determine the desired solids content of the sizing solution.

- Calculate the amount of sizing agent and water needed based on the desired solids content and batch size.

Mixing the Solution:

- Add the sizing agent to the water while mixing thoroughly.

- Use a mixer to ensure uniform distribution of the agent.

- Allow the solution to mix for an appropriate time to dissolve all the sizing agent.

Adjusting pH and Other Parameters:

- Check the pH of the solution and adjust as necessary using acids or bases.

- Confirm that other parameters, such as viscosity and temperature, meet the specified requirements.

3. How do you monitor and control the sizing process parameters (e.g., temperature, pressure, tension)?

Monitoring Process Parameters:

- Use sensors and gauges to measure temperature, pressure, tension, and other critical parameters.

- Record data at regular intervals for tracking and analysis.

- Monitor process trends to identify any deviations from desired values.

Controlling Process Parameters:

- Adjust process parameters as needed using control valves, actuators, or other mechanisms.

- Implement feedback loops to automatically regulate parameters based on deviations from setpoints.

- Tune control parameters (e.g., PID settings) to optimize process stability and performance.

4. Discuss the importance of yarn tension control in the sizing process?

- Uniform Sizing Application: Tension control ensures that yarns are evenly tensioned, enabling consistent sizing application.

- Yarn Breakage Prevention: Excessive tension can cause yarn breakage, leading to downtime and production losses.

- Improved Fabric Quality: Proper tension control ensures uniform yarn distribution, resulting in improved fabric strength, smoothness, and appearance.

- Machine Protection: Uncontrolled tension can put strain on the sizing machine, potentially damaging components.

5. How do you troubleshoot common sizing machine problems, such as yarn breakage or uneven sizing distribution?

Yarn Breakage:

- Check yarn tension settings and adjust as necessary.

- Inspect yarn for defects or weak spots.

- Examine machine components for wear or damage.

Uneven Sizing Distribution:

- Verify sizing solution preparation and consistency.

- Inspect sizing equipment for proper operation and alignment.

- Check yarn tension and adjust to ensure uniform application.

6. What maintenance procedures are essential for ensuring optimal sizing machine performance?

- Regular Cleaning: Remove dust, debris, and residual sizing agent from the machine.

- Component Inspection: Check for wear, damage, or misalignment of rollers, bearings, and other components.

- Lubrication: Apply lubricants to moving parts to reduce friction and prevent premature wear.

- Calibration: Ensure sensors, gauges, and control systems are properly calibrated for accurate measurements and process control.

7. How do you ensure the quality of sized yarns?

- Visual Inspection: Examine yarns for even sizing application, consistency, and absence of defects.

- Laboratory Testing: Perform tests to assess sizing strength, adhesion, and other quality parameters.

- Monitoring Control Charts: Establish control charts to track process parameters and identify any deviations from specifications.

- Feedback from Weaving/Knitting: Collect feedback from downstream processes to identify any issues related to sized yarn quality.

8. Explain the principles of automatic sizing machine operation?

- Programmable Logic Controller (PLC): Controls the overall operation of the machine.

- Sensors and Actuators: Monitor and adjust process parameters, such as tension, temperature, and solution flow.

- Human-Machine Interface (HMI): Provides operators with a user-friendly interface to interact with the machine.

- Closed-Loop Control: Feedback loops ensure that process parameters are maintained within desired ranges.

9. What are the safety precautions that must be taken when operating a sizing machine?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a lab coat.

- Avoid contact with moving parts and hot surfaces.

- Keep the work area clean and free of tripping hazards.

- Follow prescribed safety procedures for machine start-up, operation, and shut down.

10. How do you stay up to date with industry best practices and technological advancements in sizing?

- Attend conferences and workshops.

- Read industry publications and technical journals.

- Participate in online forums and discussion groups.

- Collaborate with colleagues and suppliers to exchange knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sizing Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sizing Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sizing Machine Tenders are responsible for the operation and maintenance of sizing machines, which are used to apply a starch-based solution to warp yarns in the textile industry.

1. Machine Operation

Operate sizing machines according to established procedures.

- Prepare size mix

- Set up and adjust machine for proper sizing

- Monitor machine operation

2. Yarn Handling

Handle warp yarns with care to prevent damage.

- Load and unload warp beams

- Inspect yarns for defects

- Make necessary adjustments to yarns

3. Quality Control

Monitor sizing process to ensure quality.

- Check size application and drying

- Inspect sized yarns for defects

- Make adjustments to machine or process as needed

4. Maintenance

Perform routine and preventative maintenance on sizing machines.

- Lubricate moving parts

- Clean and inspect machine components

- Make minor repairs and adjustments

Interview Tips

Preparing for an interview for a Sizing Machine Tender position requires thorough research, practice, and confidence. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take time to learn about the company’s history, values, and current projects. Understand the specific requirements of the Sizing Machine Tender position and how your skills and experience align with them.

Example: Highlight your knowledge of different types of sizing machines, the sizing process, and quality control techniques.

2. Practice Common Interview Questions

Prepare for common interview questions related to your technical skills, experience, and problem-solving abilities.

Example: Practice answering questions like “Describe a time you identified and resolved a problem with a sizing machine” or “How do you ensure the quality of sized yarns?”

3. Showcase Your Relevant Skills

Emphasize your technical abilities, such as machine operation, yarn handling, and quality control. Highlight your experience in maintaining and troubleshooting sizing machines.

Example: “In my previous role, I was responsible for optimizing the sizing process to improve yarn strength and reduce waste.”

4. Highlight Your Safety Awareness

Stress your understanding and adherence to safety protocols in the textile industry. Describe your experience with hazard identification and risk management.

Example: “I am trained in proper handling and storage of chemicals used in the sizing process, and I prioritize maintaining a safe work environment.”

5. Emphasize Your Problem-Solving Abilities

Interviewers seek candidates who can identify and resolve issues promptly. Describe your approach to problem-solving and provide examples where you successfully resolved sizing-related challenges.

Example: “During a production run, I encountered a machine malfunction that affected the yarn quality. I analyzed the situation, identified the root cause, and implemented a solution that minimized the impact on production.”

Next Step:

Now that you’re armed with the knowledge of Sizing Machine Tender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Sizing Machine Tender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini