Are you gearing up for an interview for a Skein Winding Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Skein Winding Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

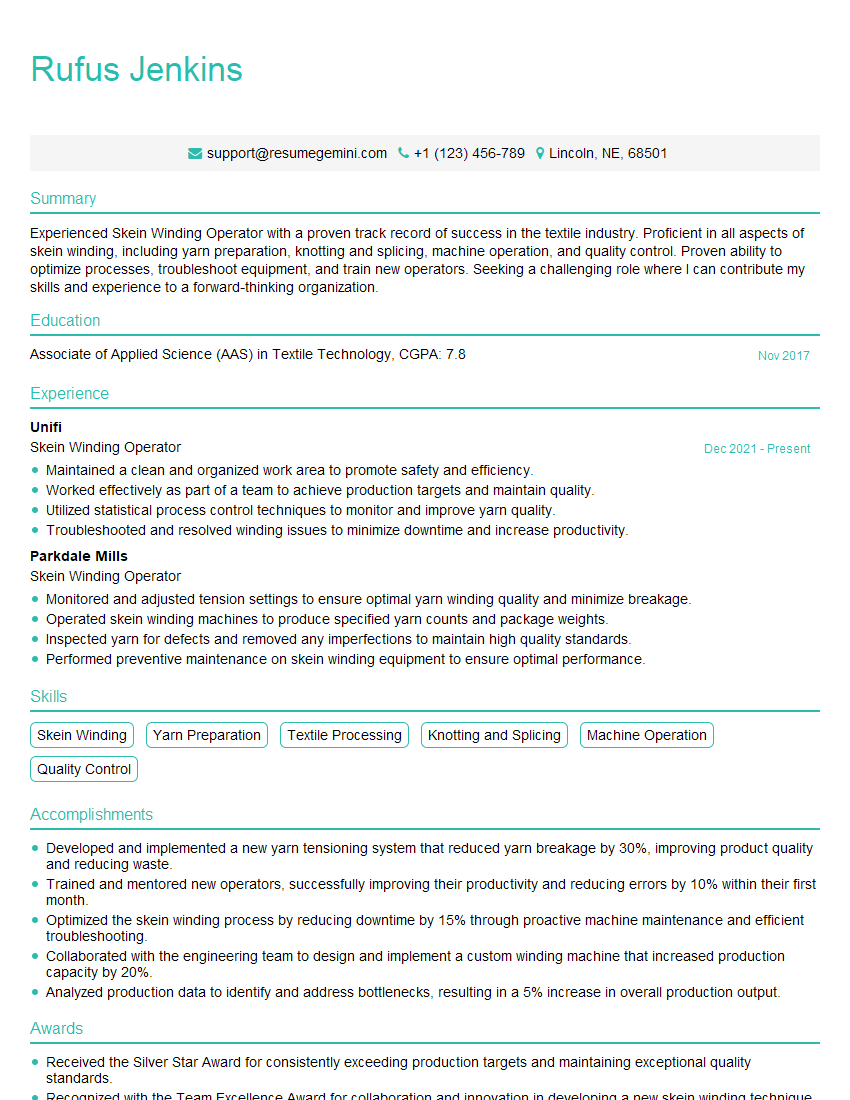

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Skein Winding Operator

1. What is the purpose of a skein winding machine?

A skein winding machine is used to wind yarn or thread into skeins, which are loose coils of yarn or thread. Skeins are used for various purposes, such as knitting, crocheting, and embroidery.

2. What are the different types of skein winding machines?

Automatic Skein Winding Machines

- These machines are fully automated and can handle multiple skeins simultaneously.

- They are typically used in large-scale yarn production facilities.

Semi-Automatic Skein Winding Machines

- These machines require manual loading and unloading of skeins.

- They are commonly used in smaller yarn mills and workshops.

Hand-Operated Skein Winding Machines

- These machines are operated manually and require the operator to guide the yarn onto the skein.

- They are mainly used for small-scale production or hobbyists.

3. What are the key factors to consider when operating a skein winding machine?

- Yarn Tension: Maintaining the correct yarn tension is crucial to ensure even winding and prevent yarn breakage.

- Skein Density: The desired skein density must be set and controlled to meet specific requirements.

- Skein Size: The machine must be adjusted to produce skeins of the desired size and weight.

- Machine Speed: The winding speed must be optimized to achieve the desired production rate while maintaining yarn quality.

4. How do you troubleshoot common problems encountered in skein winding?

- Yarn Breakage: Check for any obstructions in the yarn path and adjust the tension settings.

- Uneven Winding: Calibrate the machine and adjust the yarn tension or skein density.

- Skein Tangling: Increase the skein density or adjust the yarn tension to prevent yarn loops from forming.

- Machine Malfunction: Inspect the machine for any mechanical issues and refer to the manufacturer’s instructions for troubleshooting.

5. What safety precautions should be followed when operating a skein winding machine?

- Wear appropriate protective gear, including gloves and safety glasses.

- Keep the machine clean and clear of yarn debris.

- Be aware of moving parts and avoid loose clothing or jewelry.

- Follow the manufacturer’s safety instructions and guidelines.

6. How do you maintain a skein winding machine?

- Regular cleaning and lubrication of all moving parts.

- Calibration and adjustment of tension settings, skein size, and winding speed.

- Inspection of electrical components and wiring.

- Replacement of worn or damaged parts as required.

7. What are the different yarn materials that can be wound on a skein winding machine?

- Natural Fibers: Cotton, wool, linen, silk

- Synthetic Fibers: Polyester, nylon, acrylic

- Blended Fibers: Combinations of natural and synthetic fibers

8. How do you calculate the skein weight based on yarn count and skein length?

Skein Weight = (Yarn Count * Skein Length) / Yarn Length per Unit Weight

9. What are the industry standards for skein winding?

- Yarn Count: Expressed in tex or Ne, indicating the yarn thickness.

- Skein Length: Typically measured in meters or yards, representing the length of yarn in a skein.

- Skein Weight: Determined by the yarn count and skein length.

- Skein Density: Measured as the number of turns per unit length, affecting the compactness of the skein.

10. How do you ensure the quality of the wound skeins?

- Visual inspection for any defects or uneven winding.

- Measurement of skein length, weight, and density to verify compliance with specifications.

- Assessment of yarn tension and skein integrity.

- Regular monitoring of the winding process and machine performance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Skein Winding Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Skein Winding Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Skein Winding Operator is accountable for operating skein winding machines that produce yarn skeins for various textile applications. Their primary responsibilities include:

1. Skein Winding

Adhering to prescribed standards and specifications, the Skein Winding Operator skilfully operates skein winding machines to convert yarn into skein form. Ensuring the production of skeins with consistent dimensions, weight, and quality is paramount.

2. Machine Maintenance and Troubleshooting

The Operator plays a crucial role in maintaining the efficient operation of skein winding machines. Regular inspection, cleaning, and lubrication are indispensable tasks to maintain optimal performance and prevent breakdowns. When issues arise, the Operator promptly troubleshoots and resolves them to minimize downtime.

3. Quality Control

Quality is of utmost importance, and the Skein Winding Operator meticulously checks the output to verify the integrity and conformance of skeins to established standards. They identify and rectify defects, ensuring that only high-quality skeins are produced.

4. Process Monitoring and Optimization

The Operator closely monitors the skein winding process, identifying potential areas for improvement and implementing corrective measures to enhance efficiency. They maintain precise records, including production quantities, machine settings, and any issues encountered, for continuous process optimization.

Interview Tips

Interviews can be nerve-wracking, but with proper preparation, Skein Winding Operator candidates can increase their chances of success. Here are a few tips to help:

1. Research the Company and Position

Thoroughly researching the company and the Skein Winding Operator position demonstrates genuine interest and enthusiasm. Familiarize yourself with the company’s background, products or services, and the specific responsibilities associated with the role. This knowledge will enable you to provide thoughtful answers and ask informed questions during the interview.

2. Highlight Relevant Experience and Skills

During the interview, confidently present your relevant experience and skills that align with the job requirements. Quantify your accomplishments whenever possible, using specific examples to illustrate your contributions to previous roles. Emphasize your proficiency in operating skein winding machines, maintaining equipment, and ensuring quality standards.

3. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and professional demeanor. Your enthusiasm for the role and the industry will be evident, and it can make a lasting impression on the interviewers. Dress appropriately, speak clearly and confidently, and demonstrate genuine interest in the opportunity.

4. Prepare Questions

Prepare insightful questions to ask the interviewer. This not only shows engagement but also allows you to gather valuable information about the company, the role, and the work environment. Inquiries about the company’s growth plans, training opportunities, or sustainability initiatives can demonstrate your interest in the company’s long-term success.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Skein Winding Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Skein Winding Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.