Are you gearing up for a career in Ski Production Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Ski Production Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

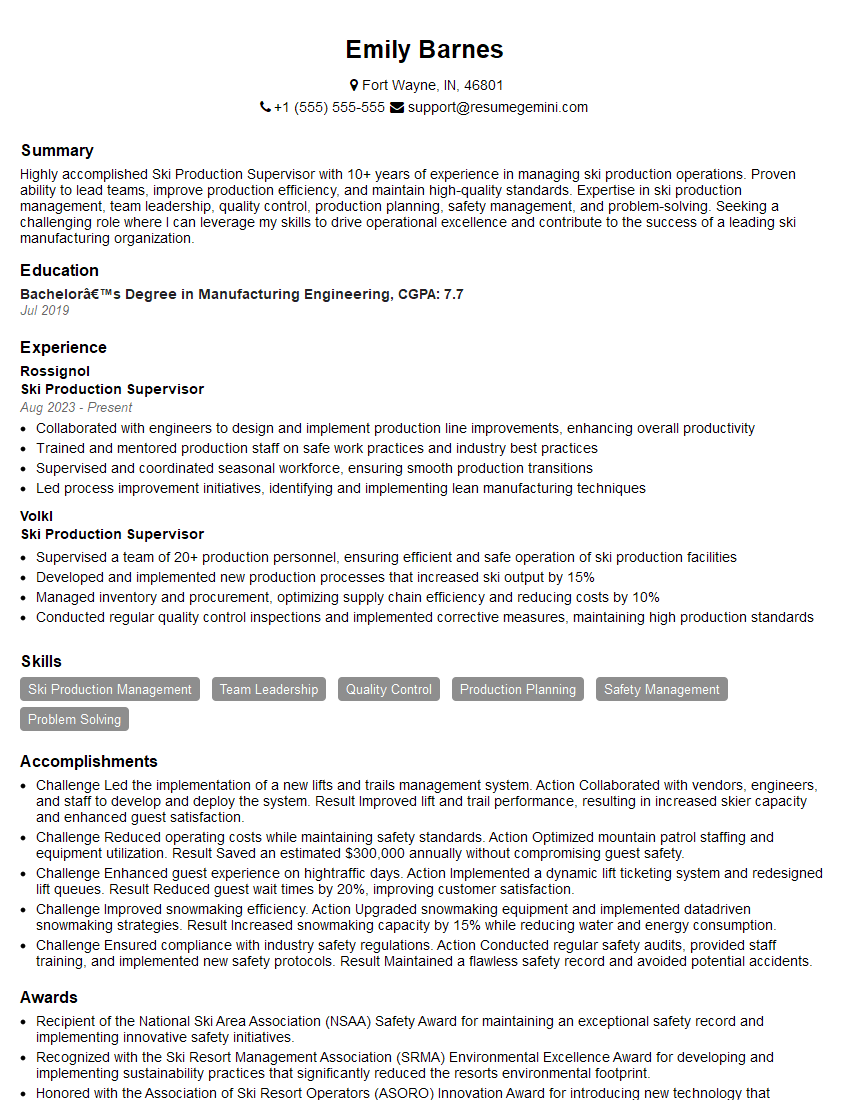

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ski Production Supervisor

1. What are the key performance indicators (KPIs) you would use to measure the success of a ski production line?

As a Ski Production Supervisor, I would use several KPIs to assess the line’s efficiency and effectiveness. These could include:

- Production output: The number of skis produced per hour or shift, ensuring we meet production targets and customer demand.

- Production quality: The percentage of skis that meet quality standards, minimizing defects and ensuring customer satisfaction.

- Line efficiency: The ratio of production output to total production time, identifying areas for improvement and reducing waste.

- Labor productivity: The number of skis produced per labor hour, optimizing resource allocation and identifying opportunities for efficiency gains.

- Material utilization: The amount of raw materials used per ski produced, ensuring cost-effectiveness and minimizing waste.

2. Describe the different types of ski construction methods and their advantages and disadvantages.

Sandwich Construction

- Advantages: Lightweight, durable, customizable, excellent performance.

- Disadvantages: More expensive, complex to manufacture, requires skilled labor.

Cap Construction

- Advantages: Affordable, easy to manufacture, impact-resistant.

- Disadvantages: Heavier, less durable, less customizable.

Monocoque Construction

- Advantages: Very lightweight, strong, versatile.

- Disadvantages: Complex and expensive to manufacture, requires specialized equipment.

3. How do you ensure the quality of skis produced on your line?

To ensure ski quality, I would implement a comprehensive quality control process involving:

- Raw material inspection: Inspecting incoming materials to ensure they meet specifications before production begins.

- In-process inspections: Conducting regular checks throughout the production process to identify and correct any deviations from standards.

- Final product testing: Performing rigorous tests on finished skis to verify their performance and compliance with quality standards.

- Quality assurance audits: Regularly reviewing and evaluating the quality control system to identify areas for improvement.

- Employee training: Ensuring all production team members are trained on quality standards and best practices.

4. How do you handle production delays and unexpected events?

To address production delays and unexpected events effectively, I would:

- Identify the root cause: Determine the underlying reason for the delay or event to prevent recurrence.

- Develop a contingency plan: Create a backup plan to minimize disruptions and maintain production output.

- Communicate effectively: Inform management, customers, and production team members about the situation and expected recovery time.

- Reallocate resources: Adjust production schedules and reassign resources to mitigate the impact on production.

- Monitor and evaluate: Continuously monitor the situation and make necessary adjustments to ensure smooth recovery.

5. How do you manage a team of production operators?

To effectively manage a team of production operators, I would:

- Set clear expectations: Communicate performance goals, standards, and responsibilities to team members.

- Provide training and support: Ensure operators have the necessary knowledge and skills to perform their tasks effectively.

- Foster teamwork and collaboration: Encourage open communication, problem-solving, and knowledge sharing among team members.

- Delegate tasks effectively: Assign responsibilities based on individual strengths and capabilities to optimize performance.

- Monitor and evaluate performance: Regularly assess operator performance and provide feedback for continuous improvement.

6. What are the safety protocols and procedures you would establish and enforce in the production area?

To ensure a safe work environment, I would establish and enforce the following safety protocols and procedures:

- Hazard identification and risk assessment: Conduct regular assessments to identify potential hazards and implement control measures.

- Machine safety: Ensure all machines are properly guarded and operated according to safety guidelines.

- Personal protective equipment (PPE): Require operators to wear appropriate PPE such as safety glasses, gloves, and hearing protection.

- Emergency preparedness: Establish clear emergency procedures and train operators on how to respond to incidents.

- Regular safety training and drills: Conduct safety training sessions and drills to educate operators on safety best practices.

7. How do you ensure that production meets environmental regulations and sustainability standards?

To ensure environmental compliance and sustainability, I would:

- Use environmentally friendly materials: Select materials that minimize environmental impact and promote sustainability.

- Implement waste reduction programs: Establish systems to reduce, reuse, and recycle waste generated during production.

- Control emissions and discharges: Implement measures to control air and water emissions to meet environmental standards.

- Comply with regulations: Stay up-to-date on environmental regulations and ensure the production process is compliant.

- Promote environmental awareness: Educate employees on environmental best practices and encourage their participation in sustainability initiatives.

8. What are the latest advancements in ski production technology that you are aware of?

I am familiar with the following advancements in ski production technology:

- Computer-aided design (CAD): Designing and prototyping skis using advanced software for precision and optimization.

- Computer-controlled machines: Utilizing CNC machines for precise shaping and cutting of ski components.

- Automated assembly lines: Implementing automated processes to streamline production and improve efficiency.

- 3D printing: Using 3D printing to create custom ski components and prototypes.

- Advanced materials: Incorporating innovative materials, such as graphene and carbon fiber, to enhance ski performance and durability.

9. How do you approach continuous improvement in the production process?

To continuously improve the production process, I would:

- Monitor key performance indicators (KPIs): Track and analyze production data to identify areas for improvement.

- Conduct regular audits and assessments: Evaluate the production process to identify inefficiencies and develop solutions.

- Encourage employee suggestions and feedback: Create an environment where employees feel comfortable sharing ideas for improvement.

- Implement Lean manufacturing principles: Apply waste reduction and efficiency enhancement techniques.

- Stay informed about industry best practices: Attend conferences, read industry publications, and network with other production professionals.

10. How do you maintain a positive and productive work environment in the ski production facility?

To maintain a positive and productive work environment, I would:

- Foster open communication: Create an environment where employees feel comfortable expressing their ideas and concerns.

- Recognize and reward employee achievements: Acknowledge and appreciate employee contributions to promote motivation.

- Provide opportunities for professional development: Encourage employees to enhance their skills and knowledge.

- Promote teamwork and collaboration: Facilitate cooperation among team members to achieve shared goals.

- Maintain a clean and organized work area: Ensure the production facility is well-maintained and conducive to productivity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ski Production Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ski Production Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Ski Production Supervisor is responsible for overseeing all aspects of ski production, from planning and scheduling to quality control and shipping. This individual must have a deep understanding of the ski manufacturing process and be able to manage a team of employees effectively. Key responsibilities include:

1. Planning and Scheduling

The Ski Production Supervisor is responsible for planning and scheduling all aspects of ski production. This includes determining the production schedule, allocating resources, and coordinating with other departments to ensure that all materials and equipment are available when needed.

- Develop and implement production schedules to meet customer demand.

- Allocate resources, including materials, equipment, and personnel, to ensure efficient production.

2. Quality Control

The Ski Production Supervisor is responsible for ensuring that all skis produced meet the company’s quality standards. This includes inspecting skis at all stages of production and taking corrective action to address any defects.

- Establish and maintain quality control standards for all produced skis.

- Inspect skis at all stages of production to identify and correct defects.

3. Inventory Management

The Ski Production Supervisor is responsible for managing the company’s ski inventory. This includes tracking inventory levels, placing orders for new materials, and ensuring that all skis are stored in a safe and secure location.

- Track inventory levels of raw materials, work-in-progress, and finished goods.

- Place orders for new materials and equipment as needed.

4. Safety Management

The Ski Production Supervisor is responsible for ensuring that all employees follow safety procedures and that the workplace is safe and free from hazards. This includes conducting safety inspections, training employees on safety procedures, and investigating accidents.

- Conduct safety inspections of the workplace and equipment.

- Train employees on safety procedures and ensure compliance.

- Investigate accidents and implement corrective actions to prevent future incidents.

Interview Tips

Preparing for an interview for the position of Ski Production Supervisor requires thorough understanding of the job role and the industry. Here are some tips to help you ace the interview:

1. Research the Company

Familiarize yourself with the company’s history, products, and mission statement. This will demonstrate your interest in the opportunity and help you align your answers with the company’s goals.

- Visit the company’s website and social media pages.

- Read industry news and publications to stay updated on the latest trends.

2. Practice Your Answers

Prepare for common interview questions by rehearsing your answers to highlight your skills and experience. Focus on providing specific examples of your accomplishments and how they relate to the job requirements.

- Use the STAR method to structure your answers: Situation, Task, Action, and Result.

- Quantify your accomplishments with data and metrics whenever possible.

3. Be Enthusiastic and Professional

Showcase your passion for the ski industry and your eagerness to contribute to the company’s success. Maintain a positive and professional demeanor throughout the interview, and dress appropriately for the occasion.

- Make eye contact, smile, and speak clearly.

- Ask thoughtful questions to demonstrate your engagement and interest.

4. Prepare Industry-Specific Questions

Asking informed questions about the company’s ski production process, industry trends, or recent innovations demonstrates your knowledge and enthusiasm for the field. It also shows that you are actively seeking to learn more.

- Research the latest advancements in ski manufacturing technology.

- Ask about the company’s approach to sustainability and environmental practices.

Next Step:

Now that you’re armed with the knowledge of Ski Production Supervisor interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Ski Production Supervisor positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini