Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Skin Former position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

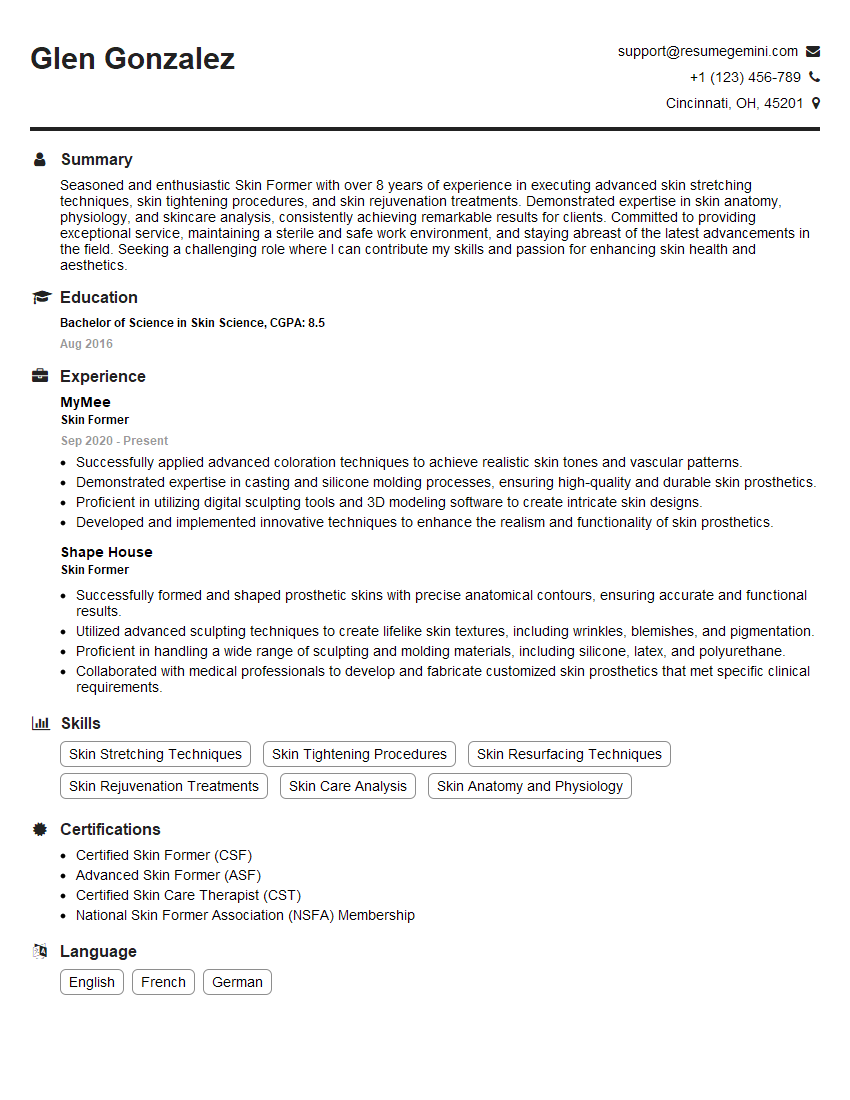

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Skin Former

1. What are the key factors to consider when selecting the appropriate skin former for a particular application?

When selecting a skin former for a particular application, several key factors should be considered:

- Type of material: Different skin formers are compatible with different materials, such as plastics, metals, or composites.

- Application temperature: The skin former must be able to withstand the temperatures used during the forming process.

- Forming pressure: The skin former must be able to withstand the forming pressures without tearing or breaking.

- Surface finish: The skin former can impart a specific surface finish to the formed part.

- Cost: The cost of the skin former should be considered in relation to the overall cost of the forming process.

2. Explain the different types of skin formers and their respective advantages and disadvantages.

Vacuum forming

- Advantages: Relatively low cost, simple process, suitable for large parts.

- Disadvantages: Limited detail, can be difficult to control thickness.

Pressure forming

- Advantages: High detail, good dimensional accuracy, suitable for complex parts.

- Disadvantages: Higher cost, more complex process, slower cycle times.

Diaphragm forming

- Advantages: High detail, good surface finish, suitable for small parts.

- Disadvantages: High cost, complex process, limited part size.

3. How do you determine the optimal forming temperature and pressure for a given material and skin former combination?

- Consult the material’s technical data sheet.

- Conduct trial runs with different temperatures and pressures.

- Use a temperature and pressure monitoring system to optimize the process.

4. What are the common troubleshooting techniques for skin forming defects?

- Wrinkles: Adjust forming temperature, pressure, or vacuum settings.

- Tearing: Use a thicker skin former, reduce forming pressure, or increase forming temperature.

- Bubbles: Increase vacuum level, adjust forming temperature, or use a release agent.

- Warping: Use a thicker skin former, reduce forming temperature, or anneal the formed part.

5. How do you maintain and store skin formers to ensure their longevity?

- Cleaning: Regularly clean skin formers with a mild detergent and water.

- Storage: Store skin formers in a cool, dry place, away from sunlight and excessive heat.

- Inspection: Regularly inspect skin formers for damage or wear and replace them as necessary.

6. Describe the steps involved in designing and fabricating a skin former for a complex part.

- Part analysis: Determine the part’s geometry, material, and forming requirements.

- Skin former design: Design the skin former to match the part’s shape and forming process.

- Material selection: Select the appropriate skin former material based on the application requirements.

- Fabrication: Fabricate the skin former using the appropriate techniques, such as CNC machining or 3D printing.

7. What are the latest advancements in skin forming technology and how are they impacting the industry?

- Digital skin forming: Uses digital data to create skin formers, enabling rapid prototyping and customized production.

- Advanced materials: New skin former materials with improved properties, such as high strength and durability.

- Automated systems: Automated skin forming systems reduce labor costs and improve efficiency.

8. How does skin forming compare to other forming processes, such as injection molding or thermoforming?

- Advantages: Relatively low cost, fast production, suitable for small batch sizes.

- Disadvantages: Limited detail, can be difficult to control thickness.

9. What is the role of a skin former in the manufacturing process?

A skin former provides the shape and support for the material during the forming process, ensuring the formation of a precise and durable product.

10. How do you ensure the quality and consistency of skin formed parts?

- Process control: Monitor and control the forming process parameters, such as temperature, pressure, and vacuum.

- Inspection: Regularly inspect skin formed parts for defects and dimensional accuracy.

- Calibration: Calibrate the forming equipment regularly to ensure accuracy and repeatability.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Skin Former.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Skin Former‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Skin Former is responsible for shaping and smoothing the surface of a variety of materials, such as wood, metal, and plastic. Some of the key responsibilities include:

Consulting with clients:

Discussing clients’ requirements, including design specifications, materials, and budgets, to determine the best skin forming solution.

Creating and modifying designs:

Using CAD software to create or modify designs for skin forming molds and fixtures.

Selecting and preparing materials:

Selecting the appropriate materials for the skin forming process, such as thermoplastics, and preparing them for forming.

Assembling and operating skin forming equipment:

Setting up and operating skin forming machines, such as vacuum forming and pressure forming machines, to shape and smooth materials.

Inspecting and testing finished products:

Inspecting finished products to ensure they meet specifications and conducting quality control tests to verify product quality.

Interview Tips

To help a candidate ace their interview for a Skin Former position, consider the following tips:

1. Research the company and the position

Familiarize yourself with the company’s website and social media presence to learn about their culture, values, and recent accomplishments. Research the specific role you are applying for to understand the key responsibilities and qualifications required.

2. Practice your answers to common interview questions

Prepare answers to common interview questions, such as “Tell me about yourself,” “Why are you interested in this position?,” and “What are your strengths and weaknesses?” Practice delivering your answers clearly and concisely, highlighting your skills and experience that are relevant to the role.

3. Showcase your technical expertise

Emphasize your technical skills and knowledge in skin forming, such as your proficiency in CAD software, experience with different skin forming techniques, and understanding of material properties. Provide specific examples of projects where you have successfully applied these skills.

4. Highlight your problem-solving abilities

Skin forming often involves troubleshooting and finding solutions to production issues. Share examples of times when you have encountered challenges in skin forming and how you overcame them. This demonstrates your ability to think critically and find innovative solutions.

5. Ask insightful questions

Asking well-thought-out questions at the end of the interview shows that you are engaged and genuinely interested in the position. Prepare questions about the company’s growth plans, the skin forming processes used, or the opportunities for professional development within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Skin Former interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!