Are you gearing up for an interview for a Skin Pass Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Skin Pass Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

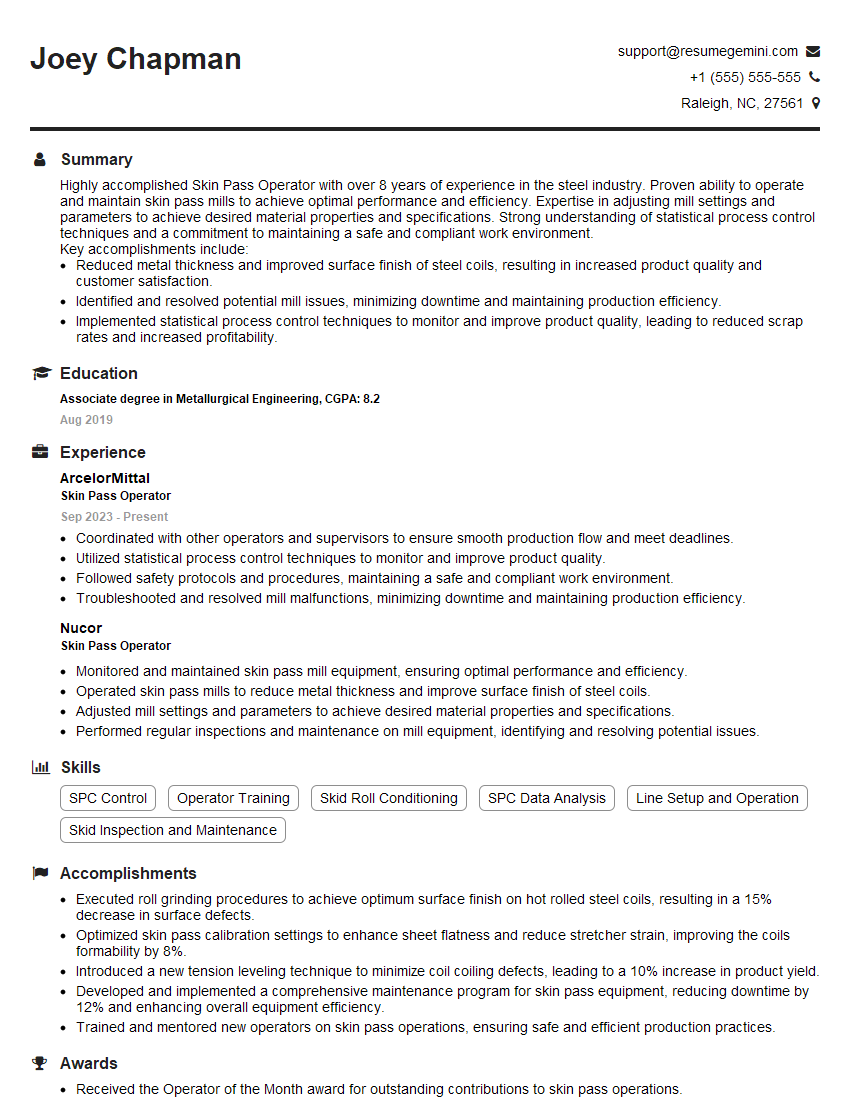

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Skin Pass Operator

1. What is the purpose of skin passing?

Skin passing is a cold rolling process that is used to improve the surface finish and mechanical properties of metal strip. It is typically used on stainless steel, but can also be used on other metals such as aluminum, copper, and brass. The process involves passing the metal strip through a series of rolls that have a highly polished surface. This polishing action removes any surface imperfections and produces a smooth, shiny finish. Skin passing can also improve the strength and hardness of the metal strip.

2. What are the different types of skin passing mills?

Reversing mills

- Reversing mills are the most common type of skin passing mill. They consist of two rolls that are mounted in a vertical frame. The metal strip is passed through the rolls in one direction, then reversed and passed through the rolls in the opposite direction. This process is repeated until the desired surface finish and mechanical properties are achieved.

Continuous mills

- Continuous mills are similar to reversing mills, but they have multiple rolls that are arranged in a series. The metal strip is passed through the rolls in one continuous direction. This process is more efficient than reversing mills, but it can produce a less uniform surface finish.

Planetary mills

- Planetary mills are a type of skin passing mill that uses a series of small rolls that are mounted on a rotating wheel. The metal strip is passed through the rolls as they rotate, which produces a very uniform surface finish. Planetary mills are typically used for high-quality applications.

3. What are the key process parameters in skin passing?

The key process parameters in skin passing are:

- Roll pressure

- Roll speed

- Strip tension

- Lubrication

These parameters must be carefully controlled in order to achieve the desired surface finish and mechanical properties.

4. What are the common defects in skin passed strip?

The common defects in skin passed strip are:

- Scratches

- Dents

- Roll marks

- Edge defects

- Surface roughness

These defects can be caused by a variety of factors, including improper process parameters, worn rolls, and contamination.

5. How do you troubleshoot skin passing problems?

Troubleshooting skin passing problems typically involves the following steps:

- Inspect the strip for defects.

- Check the process parameters.

- Inspect the rolls for wear.

- Check the lubrication system.

- Make adjustments to the process parameters or equipment as necessary.

It is important to have a good understanding of the skin passing process and the potential causes of problems in order to troubleshoot effectively.

6. What are the safety precautions that should be taken when operating a skin passing mill?

The following safety precautions should be taken when operating a skin passing mill:

- Wear proper personal protective equipment, including safety glasses, gloves, and earplugs.

- Keep the work area clean and free of debris.

- Inspect the mill and equipment regularly for any signs of damage or wear.

- Follow all operating procedures carefully.

- Never operate the mill if you are not properly trained.

By following these precautions, you can help to prevent accidents and injuries.

7. What is the difference between skin passing and temper rolling?

Skin passing and temper rolling are both cold rolling processes that are used to improve the surface finish and mechanical properties of metal strip. However, there are some key differences between the two processes.

- Skin passing is a light reduction process that is typically used to improve the surface finish of the metal strip. It does not significantly change the mechanical properties of the strip.

- Temper rolling is a heavier reduction process that is used to improve the strength and hardness of the metal strip. It can also improve the surface finish of the strip, but this is not the primary goal of the process.

The choice of which process to use depends on the desired results. If the goal is to improve the surface finish of the strip, then skin passing is the better option. If the goal is to improve the strength and hardness of the strip, then temper rolling is the better option.

8. What are the applications of skin passed strip?

Skin passed strip is used in a wide variety of applications, including:

- Automotive

- Appliances

- Construction

- Electronics

- Food and beverage

Skin passed strip is particularly well-suited for applications where a high-quality surface finish is required.

9. What are the advantages of skin passing?

The advantages of skin passing include:

- Improved surface finish

- Improved mechanical properties

- Reduced cost

- Increased productivity

Skin passing is a relatively simple and inexpensive process that can provide significant benefits.

10. What are the disadvantages of skin passing?

The disadvantages of skin passing include:

- Can only be used on thin strip

- Can cause edge defects

- Can be difficult to control

Skin passing is a specialized process that requires careful control to achieve the desired results.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Skin Pass Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Skin Pass Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Skin Pass Operator is a highly skilled professional who operates and maintains skin pass machines in a metalworking environment. They are responsible for controlling the tension, speed, and temperature of the metal as it passes through the skin pass mill, ensuring the production of high-quality, precision-finished metal products.

1. Machine Operation

The primary responsibility of a Skin Pass Operator is to skillfully operate skin pass machines. This involves continuously monitoring and adjusting machine settings, such as tension, speed, and temperature, to achieve the desired results.

- Operate skin pass machines to reduce metal thickness and improve surface quality.

- Maintain optimal machine settings to achieve specified tolerances and quality standards.

2. Product Quality Control

Ensuring the quality of the finished product is crucial for Skin Pass Operators. They perform regular inspections and tests to verify that the metal meets the required specifications.

- Inspect and measure finished products to ensure conformity with quality standards.

- Identify and rectify defects in the skin passing process to minimize product loss.

3. Equipment Maintenance

To ensure uninterrupted production and prevent costly breakdowns, Skin Pass Operators are responsible for the upkeep of the skin pass machines.

- Perform routine maintenance tasks, such as lubrication, cleaning, and adjustments.

- Troubleshoot and repair minor machine malfunctions to minimize downtime.

4. Safety and Environmental Compliance

Adherence to safety protocols and environmental regulations is paramount in the role of a Skin Pass Operator. They must follow established procedures and wear personal protective equipment to prevent accidents and injuries.

- Follow established safety procedures to minimize risks and ensure a safe work environment.

- Comply with environmental regulations, including proper waste disposal and emissions control.

Interview Tips

Preparing thoroughly for a Skin Pass Operator interview can significantly increase your chances of success. Here are some essential tips to help you ace it:

1. Research the Company and Role

Familiarize yourself with the company’s history, values, and the specific responsibilities of the Skin Pass Operator role. This knowledge will enable you to tailor your answers to the interviewer’s questions.

2. Highlight Relevant Experience and Skills

Emphasize your previous experience operating skin pass machines and maintaining metalworking equipment. If you have any certifications or training in skin passing, be sure to mention them.

3. Practice Answering Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses. Practice articulating your skills, experience, and why you are the ideal candidate for the position.

4. Be Enthusiastic and Professional

Show enthusiasm for the role and the metalworking industry. Maintain a professional demeanor throughout the interview and ask insightful questions to demonstrate your interest and engagement.

5. Prepare Questions for the Interviewer

Preparing questions to ask the interviewer shows that you are engaged and genuinely interested in the opportunity. It also provides you with an opportunity to clarify any aspects of the role or company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Skin Pass Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!