Feeling lost in a sea of interview questions? Landed that dream interview for Skip Miner, Blasting but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Skip Miner, Blasting interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

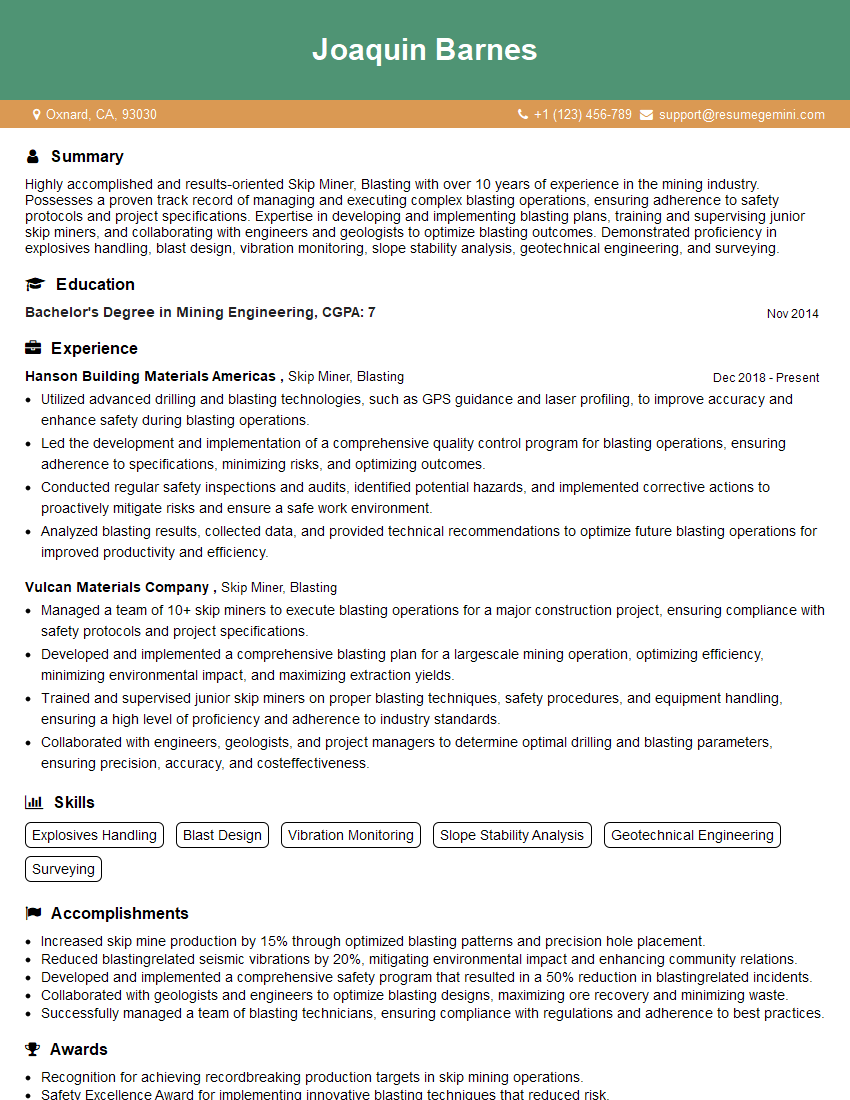

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Skip Miner, Blasting

1. What are the different types of blasting techniques used in mining?

There are various blasting techniques employed in mining, including:

- Vertical Cratering Blasting: This technique involves creating vertical craters by detonating explosives at the bottom of boreholes drilled into the rock.

- Horizontal Crater Blasting: Similar to vertical cratering blasting, but explosives are detonated horizontally to form craters in the rock.

- Line Drilling and Blasting: A series of closely spaced boreholes are drilled and charged with explosives, creating a linear cavity for controlled blasting.

- Smooth Blasting: This technique aims to minimize rock fragmentation and produce smooth surfaces by carefully designing the blast pattern and using specialized explosives.

- Cluster Blasting: Multiple boreholes are clustered together and detonated simultaneously, creating a larger blast effect for efficient rock breakage.

2. How do you determine the appropriate blasting pattern for a specific application?

Determining the optimal blasting pattern involves several factors:

- Rock properties (hardness, density, fracture characteristics)

- Desired fragmentation size and distribution

- Geology of the area (bedding planes, faults)

- Environmental considerations (noise, vibration, dust)

- Safety and operational constraints

Based on these factors, engineers calculate the borehole spacing, burden, stemming, and explosive charge to optimize blasting results.

3. What are the key safety considerations when conducting blasting operations?

Safety is paramount in blasting operations. Key considerations include:

- Proper planning and risk assessment

- Clear communication and coordination among team members

- Establishing safety zones and controlling access to the blast area

- Using appropriate blasting equipment and materials

- Following established blasting procedures and regulations

- Training and certification of blasting personnel

- Monitoring ground vibrations, airblast, and other potential hazards

4. How do you manage and mitigate the environmental impacts of blasting?

Environmental protection is a critical aspect of blasting operations. Mitigation measures include:

- Minimizing noise and vibration through proper blast design and controlled detonation

- Using dust suppressants to reduce airborne particulates

- Protecting water resources from contamination through proper handling and storage of explosives

- Rehabilitating blast sites to restore the natural environment

- Monitoring environmental parameters to assess and mitigate potential impacts

5. How do you evaluate the effectiveness of a blasting operation?

Evaluating blasting effectiveness involves:

- Assessing the fragmentation size and distribution

- Measuring ground vibration and airblast levels

- Inspecting the blasted area for overbreak or damage

- Reviewing blast records and making necessary adjustments

- Analyzing data to identify areas for improvement and optimize future operations

6. What are the advantages and disadvantages of using electronic detonators in blasting?

- Advantages:

- Precise timing and sequencing of detonations

- Improved safety by reducing the risk of misfires

- Enhanced control over blast parameters

- Reduced environmental impact due to better fragmentation

- Disadvantages:

- Higher cost compared to traditional detonators

- Requires specialized equipment and trained personnel

- Potential for electronic interference or malfunctions

7. How do you handle misfires and other blasting emergencies?

Misfires and emergencies require prompt and safe handling, including:

- Evacuating the area and securing the site

- Identifying the misfire or emergency

- Following established protocols and procedures

- Calling for assistance or contacting relevant authorities as needed

- Conducting a thorough investigation to determine the cause and prevent future incidents

8. What are the latest advancements in blasting technology that you are aware of?

- Wireless initiation systems for enhanced safety and control

- GPS and laser guidance for precise hole placement

- Advanced fragmentation modeling software for optimizing blast patterns

- Environmental monitoring systems to minimize impacts

- Automated data collection and analysis for improved decision-making

9. How do you stay up-to-date with emerging trends and best practices in blasting?

Maintaining knowledge in the field involves:

- Attending industry conferences and workshops

- Reading technical publications and journals

- Participating in professional organizations and committees

- Seeking training and certification opportunities

- Networking with other professionals in the field

10. What is your experience in working as part of a team in a mining environment?

Teamwork is crucial in blasting operations. I have extensive experience working collaboratively with geologists, engineers, and other team members to plan, execute, and evaluate blasting activities. I prioritize effective communication, coordination, and decision-making within the team to ensure safety, efficiency, and successful outcomes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Skip Miner, Blasting.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Skip Miner, Blasting‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Skip Miner, Blasting is responsible for operating a skip miner to extract ore and waste rock from underground mines. They are also responsible for maintaining and repairing the skip miner, as well as for ensuring the safety of the mining operation.

1. Operate the skip miner

The skip miner operator is responsible for controlling the skip miner and ensuring that it is operating safely and efficiently. They must be able to monitor the skip miner’s systems and make adjustments as needed. They must also be able to troubleshoot and repair the skip miner if it breaks down.

- Control the skip miner’s movement and speed

- Monitor the skip miner’s systems

- Make adjustments to the skip miner’s operation as needed

- Troubleshoot and repair the skip miner

2. Maintain the skip miner

The skip miner operator is also responsible for maintaining the skip miner. They must inspect the skip miner regularly and make any necessary repairs. They must also keep the skip miner clean and lubricated.

- Inspect the skip miner regularly

- Make any necessary repairs

- Keep the skip miner clean and lubricated

3. Ensure the safety of the mining operation

The skip miner operator is responsible for ensuring the safety of the mining operation. They must follow all safety procedures and regulations. They must also be aware of the hazards of mining and take steps to avoid them.

- Follow all safety procedures and regulations

- Be aware of the hazards of mining

- Take steps to avoid hazards

Interview Tips

To ace an interview for a Skip Miner, Blasting position, it is important to be prepared. Here are a few tips to help you:

1. Research the company and the position

Before the interview, take some time to research the company and the position. This will help you understand the company’s culture and what they are looking for in a Skip Miner, Blasting.

- Visit the company’s website

- Read articles about the company

- Talk to people who work for the company

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked. It is important to practice your answers to these questions so that you can deliver them confidently and clearly.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with skip miners?

- What are your safety procedures?

3. Be prepared to talk about your experience

The interviewer will want to know about your experience as a Skip Miner, Blasting. Be prepared to talk about your skills and abilities, as well as your experience with different types of skip miners.

- Describe your experience operating skip miners.

- Discuss your experience maintaining skip miners.

- Explain your safety procedures.

4. Be prepared to ask questions

At the end of the interview, the interviewer will likely ask you if you have any questions. This is an opportunity for you to learn more about the position and the company. It is also a chance for you to show the interviewer that you are interested in the position.

- Ask about the company’s safety record.

- Ask about the company’s training programs.

- Ask about the company’s advancement opportunities.

Next Step:

Now that you’re armed with the knowledge of Skip Miner, Blasting interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Skip Miner, Blasting positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini