Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Slag Mixer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Slag Mixer so you can tailor your answers to impress potential employers.

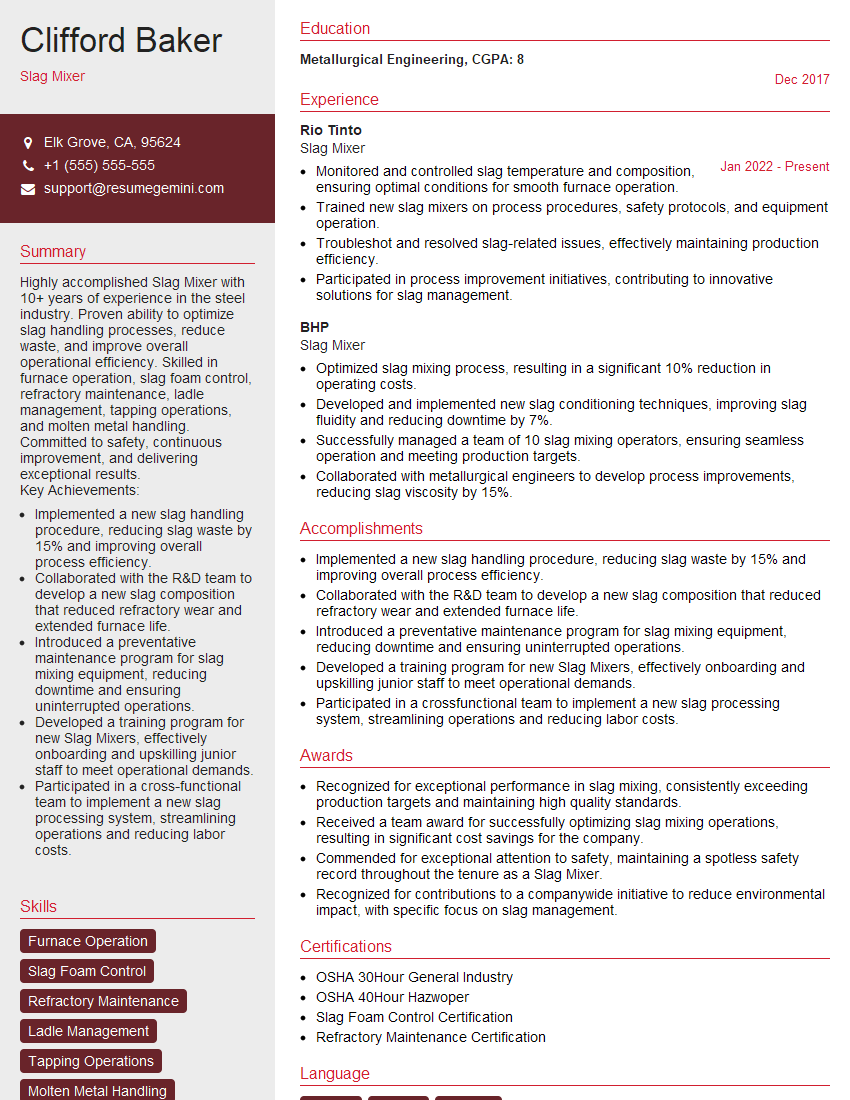

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Slag Mixer

1. What are the key responsibilities of a Slag Mixer in a steel plant?

As a Slag Mixer, my key responsibilities include:

- Operating and maintaining slag mixing equipment to ensure efficient removal of impurities from molten iron.

- Monitoring and controlling slag composition, temperature, and viscosity to meet process requirements.

- Adjusting process parameters to optimize slag removal and minimize iron loss.

- Ensuring safe and environmentally compliant operation of the slag mixing unit.

- Collaborating with production and maintenance teams to troubleshoot and resolve any issues.

2. Describe the different types of slag mixing processes used in steel production.

- Ladle Slag Mixing: Slag is mixed with molten iron in a ladle furnace using stirring or bubbling techniques.

- In-Line Slag Mixing: Slag is mixed with molten iron during the tapping process from the blast furnace or electric arc furnace.

- Injection Slag Mixing: Slag is injected into molten iron through a submerged lance or tundish.

- Rotary Slag Mixing: Slag and molten iron are mixed in a rotating vessel to promote contact and absorption of impurities.

3. What are the critical quality parameters for slag and how do you control them?

- Basicity: Controlled by the ratio of CaO to SiO2, affects slag viscosity and desulfurization efficiency.

- Viscosity: Influenced by temperature, composition, and presence of fluxes, affects slag fluidity and removal.

- Temperature: Maintained within a specific range to ensure proper slag formation and iron fluidity.

- Composition: Adjusted by adding fluxes or other materials to optimize removal of impurities.

4. What analytical techniques are used to determine slag composition and properties?

- X-Ray Fluorescence (XRF): Non-destructive analysis for elemental composition.

- Optical Emission Spectrometry (OES): Measures concentration of specific elements.

- Titration: Determines basicity and other chemical properties.

- Scanning Electron Microscopy (SEM): Provides detailed microstructure and chemical analysis.

5. How do you optimize slag mixing parameters to achieve desired results?

- Slag Composition: Adjust flux additions to achieve targeted basicity and viscosity.

- Mixing Time and Intensity: Control agitation speed and duration to maximize contact between slag and molten iron.

- Temperature: Maintain slag temperature within an optimal range for effective reactions.

- Slag Volume: Determine the appropriate slag-to-iron ratio for efficient impurity removal.

6. What safety precautions are essential in slag mixing operations?

- Personal Protective Equipment (PPE): Wear appropriate protective clothing, gloves, and respiratory masks.

- Proper Ventilation: Ensure adequate ventilation to prevent exposure to harmful fumes.

- Spill Prevention: Implement measures to contain and clean up potential slag spills.

- Ergonomic Considerations: Use proper lifting techniques and avoid overexertion.

- Training and Supervision: Provide ongoing training and supervision to ensure safe work practices.

7. What are the environmental considerations associated with slag mixing?

- Slag Disposal: Develop and implement responsible disposal methods for spent slag.

- Fume Control: Minimize emissions of harmful gases and particulates.

- Water Management: Properly handle and treat wastewater generated during slag mixing.

- Compliance: Adhere to all applicable environmental regulations and standards.

8. How do you troubleshoot common issues in slag mixing processes?

- Poor Desulfurization: Adjust slag basicity, increase mixing time, or add desulfurizing agents.

- High Slag Viscosity: Increase slag temperature, reduce slag volume, or add fluxing agents.

- Incomplete Slag Removal: Optimize stirring conditions, increase slag volume, or redesign slag handling equipment.

- Iron Losses: Control slag volume, adjust slag composition, or improve mixing efficiency.

9. Describe your experience in working with different types of slag mixing technologies.

I have experience with various slag mixing technologies, including ladle slag mixing, in-line slag mixing, and injection slag mixing. In my previous role, I successfully implemented a new in-line slag mixing system that resulted in improved desulfurization and reduced iron losses.

10. What are your strengths and weaknesses as a Slag Mixer?

My strengths include my:

- In-depth knowledge of slag mixing processes and chemistry.

- Ability to optimize slag mixing parameters to achieve desired results.

- Strong troubleshooting skills and problem-solving abilities.

- Excellent communication and interpersonal skills.

As for my weaknesses, I am always seeking opportunities to improve my technical knowledge and expand my skillset.

11. Why are you interested in joining our company?

I am eager to join your esteemed company because of its reputation for excellence in the steel industry and its commitment to innovation. I believe that my skills and experience would be a valuable asset to your team, and I am confident that I can make a significant contribution to your ongoing success.

12. What are your salary expectations?

My salary expectations are commensurate with my skills, experience, and the industry standards for this position. I am confident that I can provide a strong return on investment through my contributions to your company.

13. When are you available to start?

I am available to start as soon as possible and am excited to contribute to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Slag Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Slag Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Slag Mixers play a crucial role in the iron and steel industry, ensuring the efficient production of high-quality slag. Here are some key responsibilities that a Slag Mixer typically handles:

1. Slag Mixing and Preparation

The primary responsibility of a Slag Mixer is to mix and prepare molten slag according to specified compositional requirements. They operate and maintain slag mixers, ensuring the proper mixing of raw materials, such as fluxes and additives, to achieve the desired slag composition and viscosity.

- Operate and maintain slag mixers to mix and prepare molten slag

- Control the temperature, flow rate, and composition of molten slag

2. Slag Quality Control

Slag Mixers are responsible for maintaining the quality of the slag produced. They conduct regular tests and analysis to ensure the slag meets the required specifications. They also monitor and control the slag’s chemical composition, temperature, and viscosity to prevent any variations that could affect the quality of the final product.

- Conduct regular tests and analysis to ensure the slag meets the required specifications

- Monitor and control the slag’s chemical composition, temperature, and viscosity

3. Equipment Maintenance and Troubleshooting

Slag Mixers are responsible for maintaining and troubleshooting the equipment used in the slag mixing process. They conduct regular inspections, preventative maintenance, and repairs to ensure the equipment operates efficiently and safely. They also troubleshoot any issues that may arise during the mixing process and take corrective actions to minimize downtime.

- Conduct regular inspections, preventative maintenance, and repairs to ensure the equipment operates efficiently and safely

- Troubleshoot any issues that may arise during the mixing process and take corrective actions to minimize downtime

4. Process Optimization and Improvement

Slag Mixers are continuously looking for ways to optimize the slag mixing process and improve the quality of the slag produced. They evaluate the current process, identify areas for improvement, and implement changes to enhance efficiency, reduce waste, and increase the overall quality of the slag.

- Evaluate the current process, identify areas for improvement, and implement changes to enhance efficiency, reduce waste, and increase the overall quality of the slag

- Collaborate with other departments and teams to improve the slag mixing process

Interview Tips

To ace an interview for a Slag Mixer position, it is essential to prepare thoroughly and showcase your skills and knowledge. Here are some interview tips:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific Slag Mixer position you are applying for. Learn about the company’s history, values, and mission. Understand the key responsibilities of the role and how it aligns with your skills and experience.

- Visit the company’s website and LinkedIn page

- Read industry news and articles to stay up-to-date on the latest trends

2. Practice Your Answers

Take time to practice answering common interview questions related to the Slag Mixer role. Prepare concise and articulate responses that highlight your relevant skills and experiences. Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Prepare answers to questions about your experience in slag mixing and preparation, slag quality control, equipment maintenance, and process optimization

- Use the STAR method to provide specific examples of your accomplishments

3. Emphasize Your Knowledge and Skills

During the interview, emphasize your knowledge of slag mixing processes, slag quality control techniques, and equipment maintenance procedures. Showcase your skills in troubleshooting, process optimization, and problem-solving. Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Discuss your experience in operating and maintaining slag mixers

- Highlight your knowledge of slag chemistry and quality control

- Demonstrate your ability to troubleshoot and resolve issues

4. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic attitude. Show your passion for the slag mixing industry and your eagerness to contribute to the company’s success. Dress professionally and arrive on time for the interview. Be respectful and courteous to everyone you encounter, including the receptionist and other employees.

- Dress professionally and arrive on time for the interview

- Be polite and respectful to everyone you meet

- Maintain a positive and enthusiastic attitude

5. Ask Thoughtful Questions

At the end of the interview, take the opportunity to ask thoughtful questions about the company, the position, and the industry. This shows your engagement and interest in the role. Prepare a few questions in advance, but also listen attentively to the interviewer’s responses and ask follow-up questions to demonstrate your understanding.

- Ask about the company’s plans for future growth

- Inquire about the specific challenges and opportunities of the Slag Mixer role

- Ask about the company’s commitment to sustainability

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Slag Mixer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.