Are you gearing up for a career in Slagger? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Slagger and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

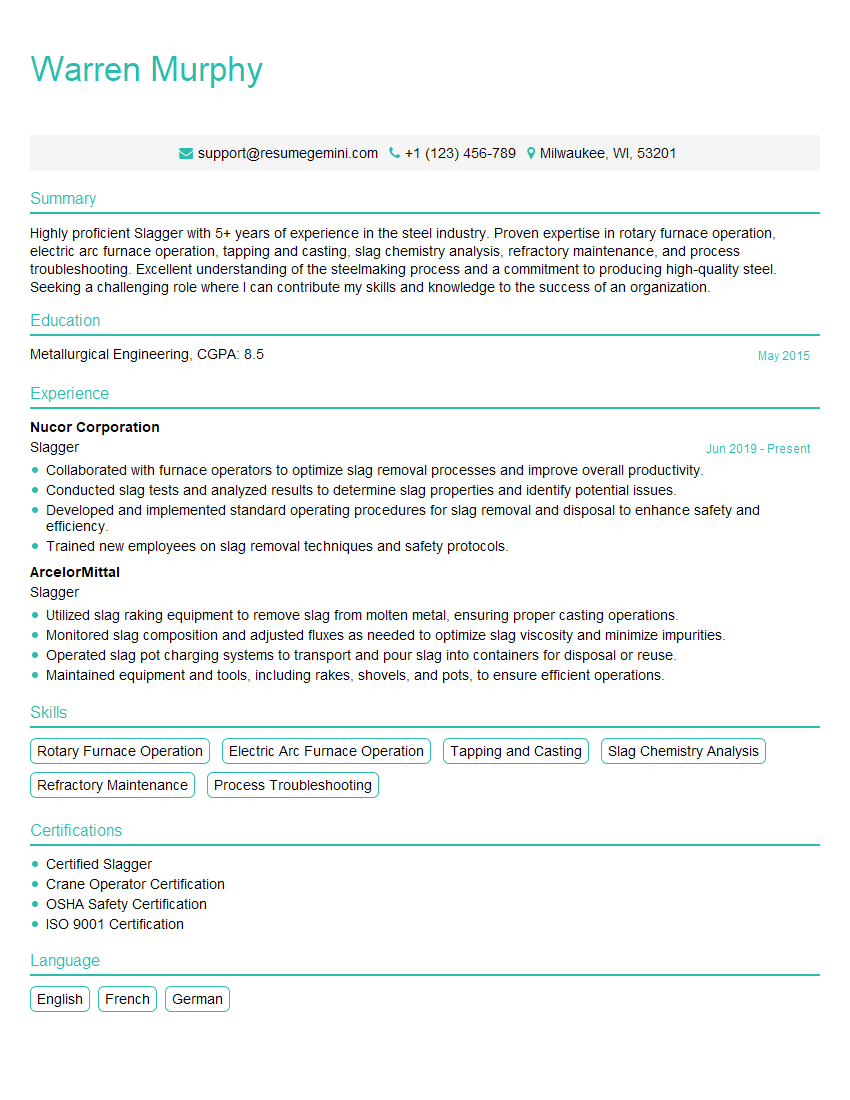

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Slagger

1. What are the key responsibilities of a Slagger?

- Operate and maintain the slagging machine to separate slag from molten metal.

- Monitor the slag composition and adjust the machine settings accordingly.

- Clean and maintain the work area, and dispose of slag waste.

- Inspect the slag and molten metal for quality and safety.

- Follow all safety procedures and regulations.

2. What are the different types of slagging machines?

Types of Slagging Machines

- Rotary Slagging Machine: Uses a rotating drum to separate slag from molten metal.

- Tilting Slagging Machine: Tilts the furnace to pour out the slag.

- Vacuum Slagging Machine: Uses a vacuum to remove slag from the molten metal.

Factors Influencing Machine Selection

- Type of slag

- Volume of slag

- Production rate

- Space available

3. What are the common challenges faced by Slaggers?

- High temperatures and noise levels.

- Handling and disposing of hazardous waste.

- Ensuring the quality of the slag and molten metal.

- Working in a physically demanding environment.

- Maintaining safety and following regulations.

4. How do you ensure the quality of the slag and molten metal?

- Monitor the slag composition using spectroscopy or other analytical methods.

- Inspect the slag visually for any defects or impurities.

- Sample and test the molten metal to ensure its quality.

- Make adjustments to the slagging process parameters as needed.

- Follow established quality control procedures.

5. How do you maintain a safe and efficient work environment?

- Wear appropriate personal protective equipment (PPE).

- Follow all safety procedures and regulations.

- Keep the work area clean and organized.

- Inspect equipment regularly and maintain it properly.

- Be aware of potential hazards and take appropriate precautions.

6. What is your experience with different types of slag?

- Basic slag: A by-product of steelmaking containing calcium and magnesium oxides.

- Acid slag: A by-product of copper smelting containing silica and alumina.

- Converter slag: A by-product of oxygen steelmaking containing iron oxides.

- Phosphate slag: A by-product of fertilizer production containing phosphorus compounds.

- Foundry slag: A by-product of iron casting containing sand and other impurities.

7. How do you handle and dispose of slag waste?

- Classify the slag waste according to its composition and characteristics.

- Store the slag waste in designated areas.

- Dispose of the slag waste in accordance with environmental regulations.

- Consider recycling or reusing the slag waste if possible.

- Follow proper waste management practices.

8. What is the importance of slag in the steelmaking process?

- Removes impurities from molten steel.

- Protects the molten steel from oxidation.

- Provides a thermal barrier between the molten steel and the furnace lining.

- Controls the temperature of the molten steel.

- Influences the final properties of the steel.

9. What are the different factors that can affect the efficiency of a slagging machine?

- Type of slag

- Volume of slag

- Temperature of the slag

- Viscosity of the slag

- Machine settings

- Maintenance of the machine

10. How do you troubleshoot common problems with a slagging machine?

- Clogged nozzle: Clear the nozzle using a rod or compressed air.

- Faulty sensor: Replace the sensor.

- Mechanical failure: Contact a qualified technician.

- Improper settings: Adjust the machine settings according to the manufacturer’s instructions.

- Lack of maintenance: Perform regular maintenance and lubrication.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Slagger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Slagger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Slagger plays a crucial role in the production process by removing slag and residues from the furnace using a variety of techniques. Their key responsibilities include:

1. Slag Removal

Using specialized tools and equipment, the Slagger removes molten slag that forms on the surface of the molten metal in the furnace.

- Operates slag removal equipment to effectively remove slag without compromising the production process.

- Ensures proper slag flow and prevents blockages in the furnace.

2. Furnace Maintenance

The Slagger is responsible for maintaining optimal furnace conditions by monitoring and adjusting equipment settings.

- Performs regular inspections of the furnace to identify and address potential maintenance issues.

- Collaborates with maintenance personnel to ensure smooth furnace operations and minimize downtime.

3. Safety and Environment

Safety is paramount for the Slagger, who ensures strict adherence to safety protocols while handling hazardous materials and operating furnace equipment.

- Follows all safety guidelines and wear appropriate personal protective equipment (PPE) at all times.

- Complies with environmental regulations and ensures proper disposal of slag and residues.

4. Quality Control

The Slagger contributes to the production of high-quality metal by monitoring the slag removal process and identifying potential defects.

- Conducts visual inspections of the molten metal to detect any impurities or inconsistencies.

- Reports any deviations from quality standards to supervisors or quality control personnel.

Interview Tips

Preparing for a Slagger interview requires a combination of technical knowledge and situational awareness. Here are some helpful tips to ace the interview:

1. Research the Company and the Role

Thoroughly research the company’s history, products, and industry standing. Familiarize yourself with the specific requirements of the Slagger role and how it aligns with the company’s overall operations.

- Visit the company’s website and social media pages.

- Read industry news and articles about the company’s involvement in the slag removal process.

2. Highlight Relevant Skills and Experience

Present a clear and concise overview of your technical skills and practical experience in slag removal. Quantify your accomplishments whenever possible using specific metrics or data.

- Emphasize your proficiency in operating slag removal equipment and maintaining furnace systems.

- Showcase any expertise you have in safety protocols and environmental regulations.

3. Prepare for Technical Questions

Prepare for questions related to slag removal techniques, furnace maintenance, and quality control. Consider the following examples:

- Describe the different methods of slag removal and their respective advantages and disadvantages.

- Explain the importance of furnace maintenance and describe some common maintenance procedures.

- Discuss the quality control measures involved in slag removal and how you ensure compliance with industry standards.

4. Demonstrate Problem-Solving Abilities

The interviewer may present hypothetical situations to assess your ability to solve problems on the job. Consider the following example:

- You encounter a sudden blockage in the slag removal system. Describe the steps you would take to identify the problem and resolve it quickly and efficiently.

5. Ask Informed Questions

Prepare thoughtful questions to ask the interviewer during the interview. This shows that you are engaged and interested in the role. Consider asking about the company’s safety culture, training opportunities, or future advancements for Slagger positions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Slagger interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.