Feeling lost in a sea of interview questions? Landed that dream interview for Slasher Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Slasher Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

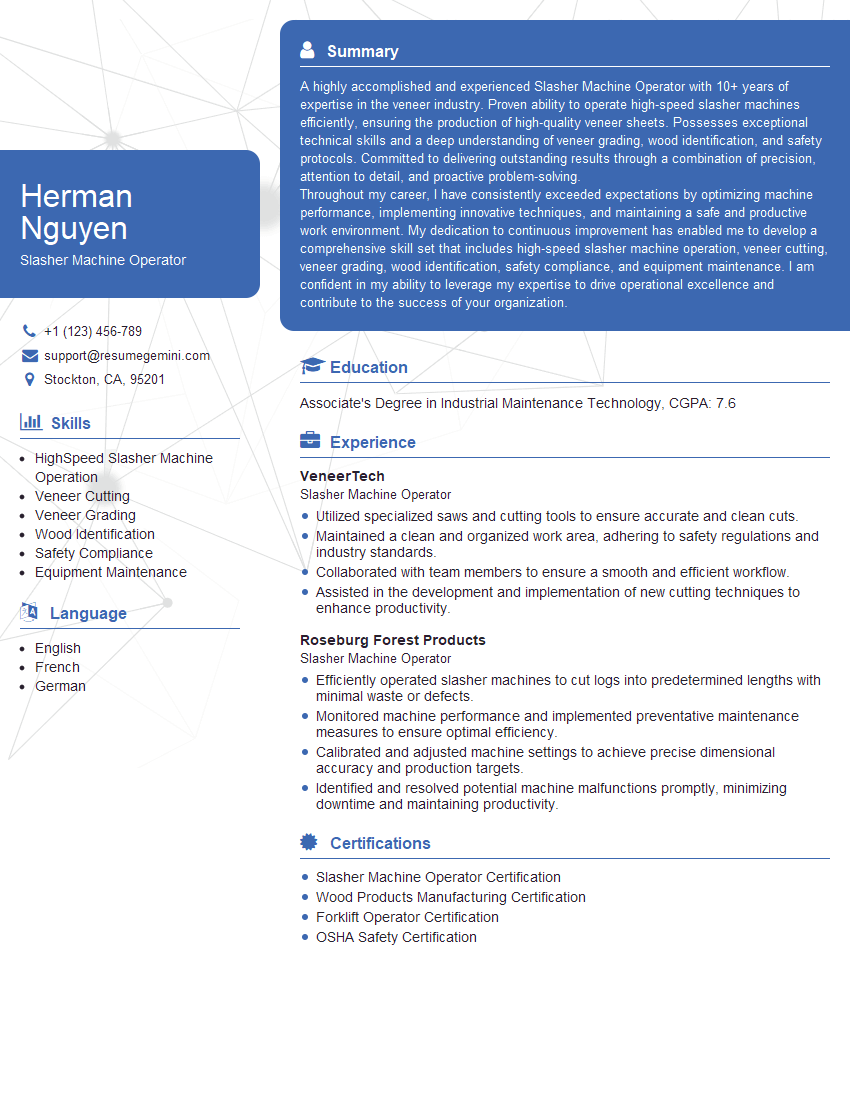

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Slasher Machine Operator

1. You are operating a slasher machine and the blade is not feeding material properly. What could be the problem and how would you troubleshoot it?

The issue could be caused by a variety of factors. Here are some troubleshooting steps:

- Check the blade tension: Make sure the blade is properly tensioned. If it’s too tight, it could break. If it’s too loose, it could slip and cause the material to jam.

- Check the blade sharpness: A dull blade will not cut properly and could cause the material to jam.

- Check the feed rate: The feed rate should be set according to the type of material being cut. If the feed rate is too fast, the blade could jam.

- Check the material thickness: The slasher machine may not be able to cut through material that is too thick.

- Check for any obstructions: There may be something blocking the blade from cutting properly.

2. Describe the different types of blades used on a slasher machine and explain when each type is appropriate.

Types of Blades

- High-speed steel (HSS) blades: HSS blades are made from a type of steel that is hardened to resist wear. They are commonly used for cutting soft materials, such as wood and plastic.

- Carbide-tipped blades: Carbide-tipped blades are made from a type of steel that is coated with carbide, a hard material that is resistant to wear. They are commonly used for cutting hard materials, such as metal and concrete.

- Diamond blades: Diamond blades are made from a diamond, the hardest known material. They are commonly used for cutting very hard materials, such as glass and ceramic tile.

Choosing the Right Blade

- Consider the material being cut: The type of blade must be appropriate for the material being cut. For example, a HSS blade would be used for cutting wood, while a diamond blade would be used for cutting glass.

- Consider the thickness of the material: The thickness of the blade must be appropriate for the thickness of the material being cut. For example, a thin blade would be used for cutting thin material, while a thick blade would be used for cutting thick material.

- Consider the speed of the machine: The speed of the machine must be appropriate for the blade being used. For example, a high-speed machine would require a blade that can withstand high speeds.

3. What are the safety precautions that should be taken when operating a slasher machine?

The following safety precautions should be taken when operating a slasher machine:

- Wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- Keep hands and feet away from the blade.

- Do not operate the machine if you are tired or under the influence of drugs or alcohol.

- Be aware of your surroundings and keep others away from the machine.

- Follow all manufacturer’s instructions.

4. How do you maintain a slasher machine?

The following steps can be taken to maintain a slasher machine:

- Clean the machine regularly: Remove any sawdust or other debris from the machine.

- Lubricate the machine regularly: Lubricate all moving parts of the machine.

- Check the blade regularly: Inspect the blade for any cracks or damage.

- Replace the blade when necessary: Replace the blade when it becomes dull or damaged.

- Follow all manufacturer’s instructions: Consult the manufacturer’s manual for specific maintenance instructions.

5. What are some common problems that can occur with a slasher machine and how would you fix them?

Some common problems that can occur with a slasher machine include:

- The blade is not cutting properly: This could be caused by a dull blade or a blade that is not properly tensioned.

- The machine is vibrating excessively: This could be caused by a loose blade or a problem with the bearings.

- The machine is making a loud noise: This could be caused by a loose blade or a problem with the motor.

- The machine is leaking oil: This could be caused by a leak in the hydraulic system.

To fix these problems, you can follow the troubleshooting steps described in the previous questions.

6. What is your experience with different types of slasher machines?

I have experience operating a variety of slasher machines, including both manual and automatic machines. I am also familiar with different types of blades and how to select the right blade for the job. I have a strong understanding of the safety precautions that must be taken when operating a slasher machine and I am able to maintain and troubleshoot the machine as needed.

7. What are your strengths and weaknesses as a Slasher Machine Operator?

My strengths include:

- My experience operating a variety of slasher machines.

- My knowledge of different types of blades and how to select the right blade for the job.

- My understanding of the safety precautions that must be taken when operating a slasher machine.

- My ability to maintain and troubleshoot the machine as needed.

My weaknesses include:

- I am not yet familiar with all of the specific features of this particular slasher machine.

- I do not have any experience operating a slasher machine in a production environment.

8. What are your salary expectations?

My salary expectations are commensurate with my experience and qualifications. I am confident that I can make a significant contribution to your company and I am eager to discuss my salary expectations in more detail.

9. Why are you interested in this job?

I am interested in this job because it offers me the opportunity to use my skills and experience to make a difference in your company. I am also eager to learn more about the slasher machine industry and I believe that this job would provide me with the opportunity to do so.

10. Do you have any questions for me?

I do have a few questions:

- What is the production environment like?

- What are the company’s safety protocols?

- What are the opportunities for advancement?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Slasher Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Slasher Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Slasher Machine Operator is responsible for operating and maintaining a slasher machine, which is used to cut logs into smaller pieces for further processing. Key responsibilities include:

1. Machine Operation

Operate the slasher machine efficiently and safely, following established procedures and safety guidelines.

- Position logs on the machine’s conveyor system.

- Control the machine’s speed and cutting settings.

2. Machine Maintenance

Perform daily maintenance checks and minor repairs on the slasher machine.

- Lubricate moving parts.

- Check and adjust belts and chains.

3. Quality Control

Monitor the quality of the cut lumber and make adjustments to the machine as needed.

- Ensure that logs are cut to the specified length and dimensions.

- Inspect lumber for defects and remove any damaged pieces.

4. Teamwork and Communication

Work as part of a team to achieve production goals and resolve any issues that may arise.

- Communicate effectively with supervisors, maintenance personnel, and other operators.

- Participate in problem-solving and continuous improvement initiatives.

Interview Tips

Preparing for an interview as a Slasher Machine Operator requires a thorough understanding of the role’s responsibilities and the industry. Here are some tips to help you ace the interview:

1. Research the Company and Position

Research the company’s history, products, and culture to demonstrate your interest and understanding of the industry.

- Visit the company’s website and LinkedIn page.

- Read industry publications and news articles.

2. Highlight Your Experience and Skills

Emphasize your previous experience operating and maintaining slasher machines, including your specific accomplishments.

- Quantify your achievements using specific metrics, such as production output or reduced downtime.

- Provide examples of your problem-solving abilities and how you have resolved issues in the past.

3. Show Your Safety Consciousness

Safety is paramount in this role. Highlight your commitment to following safety procedures and maintaining a clean and organized work environment.

- Discuss your knowledge of industry safety regulations.

- Describe your experience with conducting safety inspections and reporting hazards.

4. Practice Your Communication Skills

Effective communication is essential for teamwork and problem-solving. Practice answering common interview questions and demonstrate your ability to articulate your ideas clearly.

- Prepare for questions about how you handle conflicts or resolve unexpected situations.

- Come prepared with questions to ask the interviewer, showing your interest and engagement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Slasher Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.