Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Slasher Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

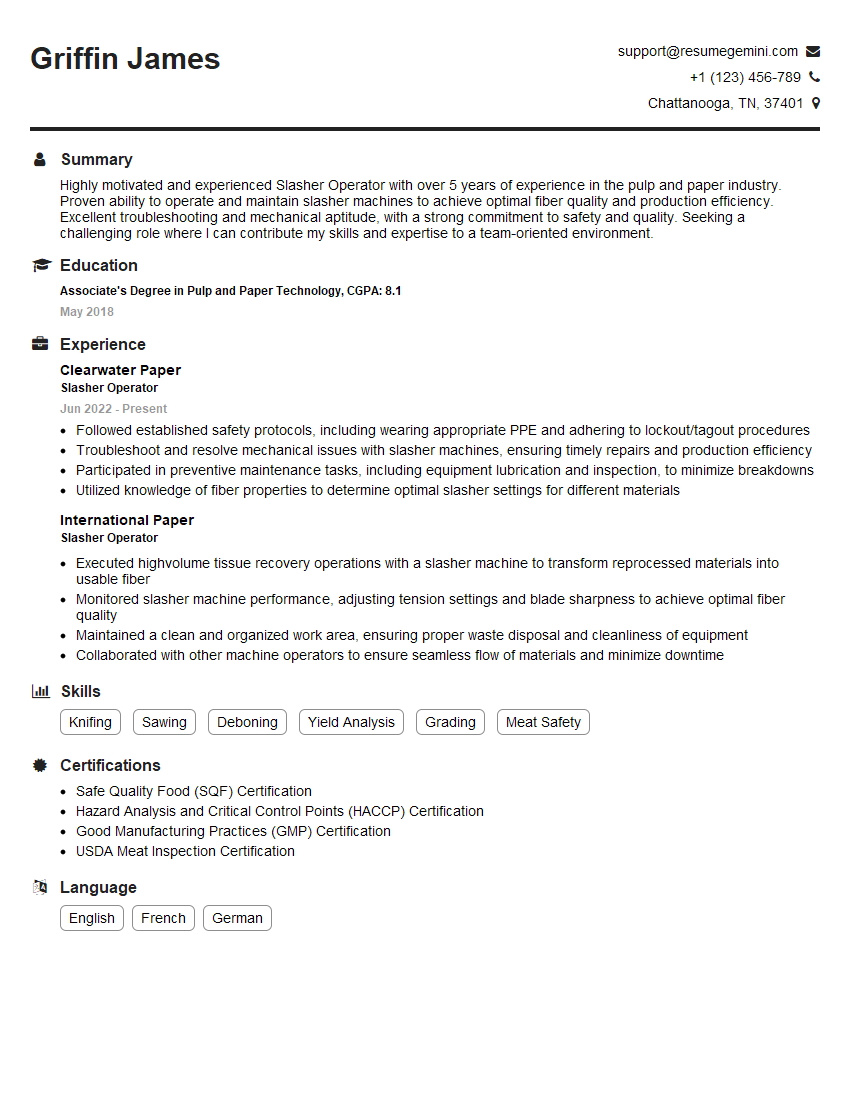

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Slasher Operator

1. What is the purpose of a slasher operator and what are the key responsibilities of this role?

A slasher operator is responsible for operating a slasher machine, which cuts or shreds materials such as paper, cardboard, or plastic. The key responsibilities of a slasher operator include:

- Loading and unloading materials onto the slasher machine

- Operating the slasher machine to cut or shred materials to the desired size

- Maintaining and cleaning the slasher machine

- Monitoring the slasher machine for any malfunctions or problems

- Following safety procedures and regulations

2. What are the different types of slasher machines and what are their respective applications?

Rotary Slasher

- Uses a rotating blade to cut materials

- Suitable for cutting a wide variety of materials, including paper, cardboard, plastic, and textiles

Guillotine Slasher

- Uses a sharp blade that descends vertically to cut materials

- Suitable for cutting thick materials, such as heavy paper and cardboard

Shear Slasher

- Uses two blades that slide past each other to cut materials

- Suitable for cutting thin materials, such as paper and plastic film

3. What are the safety precautions that must be taken when operating a slasher machine?

The following safety precautions must be taken when operating a slasher machine:

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs

- Ensure that the machine is properly guarded and maintained

- Never reach into the machine while it is running

- Keep the work area clean and free of debris

- Follow all safety procedures and regulations

4. What are the different types of materials that can be processed by a slasher operator?

A slasher operator can process a wide variety of materials, including:

- Paper

- Cardboard

- Plastic

- Textiles

- Rubber

5. How does a slasher operator determine the optimal cutting settings for different materials?

A slasher operator determines the optimal cutting settings for different materials based on the following factors:

- The type of material being cut

- The thickness of the material

- The desired cut size

- The speed of the slasher machine

6. What are the common maintenance tasks that a slasher operator must perform?

Common maintenance tasks that a slasher operator must perform include:

- Lubricating the machine

- Cleaning the machine

- Inspecting the machine for wear and tear

- Replacing worn or damaged parts

- Calibrating the machine

7. What are the potential hazards associated with operating a slasher machine and how can they be minimized?

The following are potential hazards associated with operating a slasher machine and how they can be minimized:

- Cuts and lacerations: Wear appropriate safety gear, keep the work area clean, and never reach into the machine while it is running

- Flying debris: Wear safety glasses and keep the work area clean

- Noise: Wear earplugs

- Pinch points: Keep hands away from moving parts

- Electrical hazards: Ensure that the machine is properly grounded and maintained

8. What are the key performance indicators (KPIs) for a slasher operator?

Key performance indicators (KPIs) for a slasher operator include:

- Production output

- Quality of cuts

- Machine uptime

- Safety record

9. How do you stay up-to-date on the latest slasher machine technology and best practices?

I stay up-to-date on the latest slasher machine technology and best practices by:

- Attending industry conferences and trade shows

- Reading industry publications

- Consulting with equipment manufacturers

- Networking with other slasher operators

10. What are your career goals and how does this slasher operator position fit into those goals?

My career goal is to become a Production Supervisor. I believe that this slasher operator position is a great stepping stone towards achieving my goal. This position will allow me to develop the skills and experience that are necessary to be successful in a supervisory role, such as leadership, communication, and problem-solving.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Slasher Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Slasher Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Slasher operators play a crucial role in the converting process within the steel industry. Their key responsibilities revolve around operating and maintaining slasher equipment used to cut steel slabs into desired lengths.

1. Equipment Operation

Slasher operators are responsible for the safe and efficient operation of slasher equipment. Their duties include:

- Loading and positioning steel slabs onto the slasher line

- Determining cutting parameters and adjusting equipment accordingly

- Monitoring the cutting process to ensure slabs are cut to specifications

- Troubleshooting and resolving equipment malfunctions or stoppages

2. Quality Control

Slasher operators are responsible for maintaining high standards of product quality. They perform regular inspections and checks to ensure:

- Slabs are cut to the correct dimensions and tolerances

- Cut surfaces are smooth and free of defects

- Equipment is functioning properly to prevent potential quality issues

3. Safety and Maintenance

Safety is paramount in the role of a slasher operator. They adhere to established safety protocols and guidelines to ensure a safe working environment. Additionally, they perform regular maintenance tasks to keep equipment in optimal condition, including:

- Cleaning and lubricating equipment components

- Inspecting and replacing worn or damaged parts

- Reporting any safety hazards or equipment issues to supervisors

4. Production Efficiency

Slasher operators contribute to overall production efficiency by:

- Optimizing cutting parameters to minimize waste and maximize yield

- Working closely with other team members to ensure a smooth flow of production

- Adhering to production schedules to meet customer demands

Interview Tips

Preparing for a Slasher Operator interview requires a thoughtful approach. Here are some valuable tips to help you ace the interview:

1. Research the Company and Industry

Demonstrate your interest and knowledge by researching the company’s background, products, and the steel industry. Understanding the company’s culture and values will help you align your responses with their priorities.

2. Highlight Relevant Skills and Experience

Emphasize your relevant skills and experience related to slasher operation and metalworking. Quantify your accomplishments with specific examples that showcase your technical abilities, safety awareness, and problem-solving capabilities.

3. Be Prepared for Technical Questions

Interviews for Slasher Operator positions often involve technical questions to assess your understanding of the equipment and process. Prepare for questions related to slasher operation, quality control procedures, safety regulations, and troubleshooting techniques.

4. Practice Common Interview Questions

Anticipate common interview questions such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Practice your responses to deliver clear and concise answers that highlight your qualifications and enthusiasm.

5. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for your interview. A polished appearance and punctuality demonstrate respect for the interviewer and the company.

Next Step:

Now that you’re armed with the knowledge of Slasher Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Slasher Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini