Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sleeve Presser Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

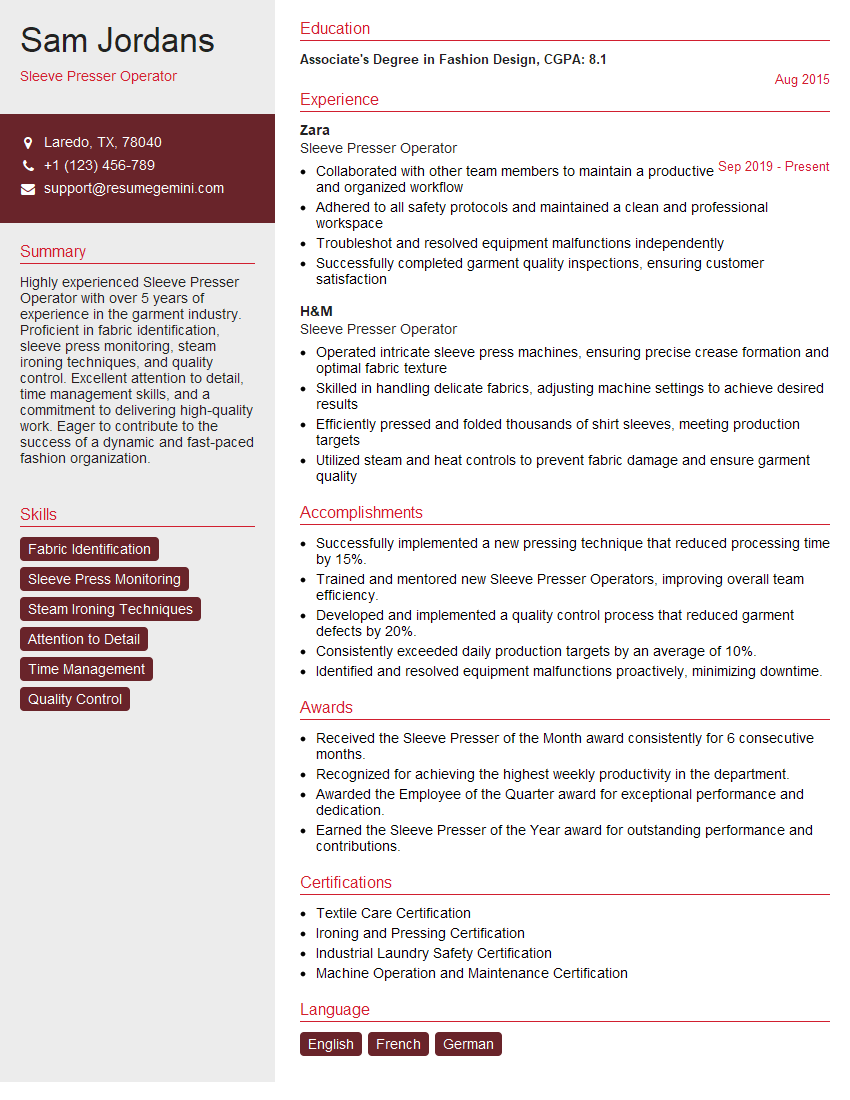

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sleeve Presser Operator

1. How would you identify and resolve any potential challenges or issues that may arise while operating a sleeve pressing machine?

I would first try to understand the root cause of the issue. Once I have identified the cause, I would then take the appropriate steps to resolve it. For example, if the machine is not heating up properly, I would check the power supply, the heating element, and the thermostat. I would also consult the machine’s manual for troubleshooting tips.

2. What is the best way to improve the efficiency and productivity of a sleeve pressing machine?

Optimizing machine settings

- Adjusting the pressing temperature and pressure to suit the fabric type.

- Calibrating the machine regularly to ensure accurate pressing results.

Streamlining the workflow

- Organizing the workspace to minimize unnecessary movements.

- Batching similar sleeves together to reduce machine adjustments.

Maintaining the machine

- Performing regular cleaning and maintenance to prevent breakdowns.

- Inspecting the machine for potential issues and addressing them promptly.

3. How would you ensure that the sleeves are pressed to the desired quality standards?

I would first familiarize myself with the specific quality standards required for the particular garments. I would then visually inspect each sleeve before pressing to identify any defects or areas that require special attention. During pressing, I would carefully control the temperature and pressure to achieve the desired results. I would also use a pressing cloth or pad to protect the fabric from damage.

4. What are the safety precautions that should be taken when operating a sleeve pressing machine?

- Always wear appropriate safety gear, including gloves and safety glasses.

- Keep the work area clean and free of obstructions.

- Be aware of the machine’s moving parts and avoid loose clothing or jewelry that could get caught.

- Never reach into the machine while it is in operation.

- Turn off and unplug the machine before performing any maintenance or repairs.

5. What are some tips for achieving a professional-looking press on sleeves?

- Use a sharp crease to create a clean, defined line.

- Press the sleeve with even pressure to avoid puckering or wrinkles.

- Hold the iron in place for a few seconds to allow the heat to penetrate the fabric.

- Use a pressing cloth or pad to protect delicate fabrics.

- Allow the sleeve to cool completely before handling it to prevent wrinkles from setting.

6. What are the different types of fabrics that you have experience pressing and how do you adjust your technique for each type?

I have experience pressing a wide range of fabrics, including cotton, silk, linen, wool, and synthetic blends. I adjust my technique for each type of fabric based on its unique characteristics. For example, I use a lower temperature and pressure for delicate fabrics like silk and a higher temperature and pressure for heavier fabrics like wool.

7. How do you stay up-to-date on the latest techniques and technologies in sleeve pressing?

I regularly read industry publications and attend trade shows to stay informed about the latest techniques and technologies in sleeve pressing. I also consult with more experienced colleagues and seek out opportunities to learn from them.

8. What are your thoughts on automation in the sleeve pressing industry?

I believe that automation has the potential to improve efficiency and productivity in the sleeve pressing industry. However, it is important to ensure that automation does not replace the need for skilled workers. I see automation as a tool that can complement the work of sleeve pressers and help them to achieve better results.

9. How do you manage to maintain high levels of productivity while ensuring quality in your work?

I prioritize my tasks and focus on completing the most important ones first. I also take regular breaks to avoid fatigue and maintain my focus. I always double-check my work to ensure that it meets the required quality standards.

10. What is your favorite part about working as a Sleeve Presser Operator?

I enjoy the satisfaction of seeing the finished product and knowing that I played a part in creating a high-quality garment. I also appreciate the opportunity to work with a team of skilled professionals and to learn from their experience.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sleeve Presser Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sleeve Presser Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sleeve Presser Operators are responsible for pressing and finishing sleeves using industrial ironing equipment in garment factories and laundries. Their primary tasks include:

1. Sleeve Pressing and Finishing

Operate industrial sleeve pressing machines to press and shape sleeves of various sizes and styles.

- Adjust machine settings to achieve desired pressure, temperature, and steam levels.

- Identify and address any inconsistencies or defects in the sleeve during pressing.

2. Maintenance and Inspection

Inspect and clean sleeve pressing machines regularly to ensure optimal performance.

- Perform minor maintenance tasks, such as replacing worn parts and adjusting tension.

- Report any major malfunctions or repairs to the supervisor.

3. Quality Control

Adhere to established quality standards by inspecting pressed sleeves for defects such as wrinkles, creases, or stains.

- Identify and rectify any quality issues promptly.

- Maintain production standards by ensuring that pressed sleeves meet specifications.

4. Safety Compliance

Follow all safety protocols and regulations related to the operation of industrial pressing equipment.

- Wear appropriate personal protective equipment (PPE).

- Handle and operate machinery safely to prevent injuries.

Interview Tips

Preparing for an interview for a Sleeve Presser Operator position requires thorough preparation and knowledge of the role. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, culture, and values. Research the role and industry to understand its requirements and responsibilities.

2. Practice Your Answers

Anticipate common interview questions and prepare your answers in advance. Practice delivering them concisely and professionally.

3. Highlight Your Experience and Skills

Emphasize your experience in sleeve pressing and finishing, including any specialized techniques or machinery you have operated. Highlight your attention to detail and quality control abilities.

4. Demonstrate Your Safety Awareness

Stress your understanding of safety protocols and your commitment to following them strictly. Describe any previous safety training or certifications you have obtained.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your engagement and interest in the position. Inquire about the company’s growth plans or any specific challenges related to the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sleeve Presser Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!