Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Sleeve Sewer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Sleeve Sewer so you can tailor your answers to impress potential employers.

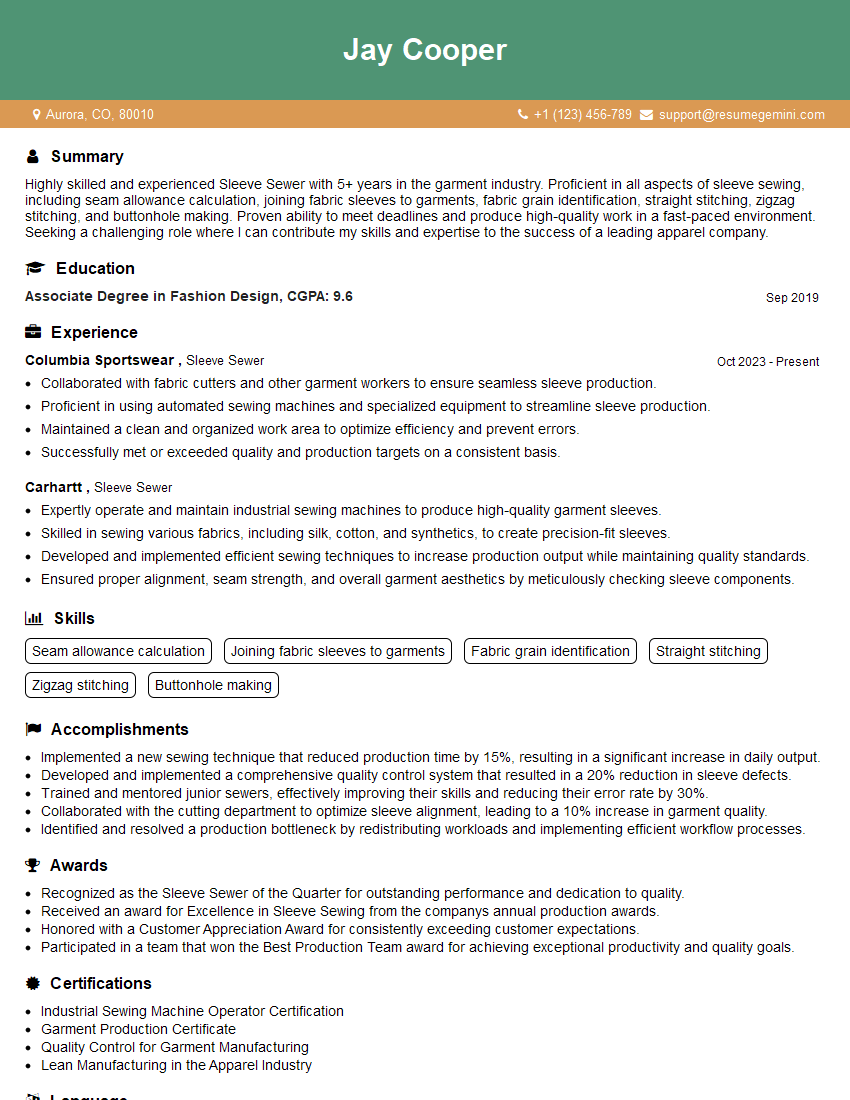

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sleeve Sewer

1. Describe the process of sewing a sleeve?

The process of sewing a sleeve involves several steps:

- Preparation: Gather the necessary materials, including the garment, sleeve, thread, and sewing machine.

- Measuring and marking: Determine the desired sleeve length and width; mark the measurements on the garment and sleeve fabric.

- Pinning: Align the sleeve and garment and pin them together along the shoulder seam.

- Basting: Sew a temporary stitch along the pinned seam to hold the fabrics in place.

- Sewing: Change to a permanent stitch and sew along the seam allowance, removing the basting stitches as you go.

- Finishing: Press the seam open, trim any excess fabric, and reinforce the seam with topstitching or other finishing techniques.

2. What are common sleeve styles and how should they be sewn?

Set-in sleeves

- Sewn into the armhole of the garment, creating a smooth transition.

- Require precise measuring and shaping to fit the armhole.

Raglan sleeves

- Cut as a continuous piece with the garment, extending from the neckline to the underarm.

- Provide a comfortable and relaxed fit, suitable for casual garments.

Kimono sleeves

- Straight and wide, attached to the garment with a straight seam.

- Common in traditional Japanese garments and flowy dresses.

3. What types of sewing machines are best suited for sleeve sewing?

Suitable sewing machines for sleeve sewing include:

- Flatlock machines: Create durable flat seams, ideal for garments that undergo heavy wear.

- Overlock machines: Trim and overcast seam edges, preventing fraying.

- Blind hem machines: Create invisible hems along the bottom of sleeves.

- Topstitch machines: Reinforce seams and add decorative details.

4. How do you ensure accurate sleeve length and fit?

- Measure accurately: Use a measuring tape or ruler to determine the desired sleeve length and width.

- Marking and pinning: Mark the measurements on the garment and sleeve fabric and pin them together precisely.

- Basting: Sew a temporary stitch to hold the fabrics in place before sewing the permanent seam.

- Try-on and adjustments: Have the garment fitted on the individual to check the sleeve length and fit; make any necessary adjustments.

5. What are the common challenges in sleeve sewing and how do you overcome them?

- Bulky seams: Use a tapered seam allowance, trim excess fabric, and press seams open to reduce bulk.

- Sleeve cap puckering: Ease the fabric around the sleeve cap by gathering or pleating the excess.

- Sleeve twisting: Rotate the sleeve and garment evenly as you sew to prevent twisting.

- Uneven stitching: Ensure the sewing machine is properly threaded, tensioned, and maintain a steady stitching pace.

6. How do you handle different types of fabrics when sewing sleeves?

Adjust sewing techniques and machine settings based on fabric type:

- Lightweight fabrics: Use fine needles, short stitch lengths, and lightweight thread.

- Medium-weight fabrics: Use standard needles and thread, adjust stitch length as needed.

- Heavyweight fabrics: Use heavy-duty needles and thread, increase stitch length, and consider using a seam guide.

7. What is the role of interfacing in sleeve construction?

- Provides stability: Reinforces the sleeve cap and prevents stretching or sagging.

- Improves drape: Gives sleeves a smooth and professional finish.

- Reduces wrinkling: Helps maintain the shape and structure of the sleeve.

8. How do you maintain quality control while sewing sleeves?

- Accurate measurement and marking: Ensures precise fit and symmetry.

- Proper tension and stitch length: Produces even and durable seams.

- Regular inspection: Checks for any stitching errors, loose threads, or fabric puckering.

- Pressing: Smooths seams and improves overall appearance.

9. How do you stay up-to-date with current trends and techniques in sleeve sewing?

- Industry publications and resources: Read trade magazines, attend workshops, and consult online tutorials.

- Networking: Connect with other sewers and designers to exchange ideas and knowledge.

- Online learning platforms: Take online courses or webinars to enhance skills and learn new techniques.

10. What are your strengths and weaknesses as a Sleeve Sewer?

Strengths:

- Precision and accuracy: Meticulous attention to detail, ensuring high-quality seams and precise fit.

- Problem-solving skills: Ability to identify and overcome challenges in sleeve construction.

- Knowledge of fabrics and techniques: Expertise in working with various fabrics and utilizing appropriate sewing techniques.

Weaknesses:

- Speed: While maintaining accuracy, working on improving sewing speed to meet production demands.

- Embroidery skills: Limited experience in decorative sleeve embroidery techniques, but eager to develop these skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sleeve Sewer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sleeve Sewer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sleeve Sewers are responsible for sewing sleeves onto garments, such as shirts, jackets, and dresses. They play a crucial role in the garment manufacturing process by ensuring the accuracy and quality of the finished product.

1. Sewing Sleeves

Sleeve Sewers are required to sew sleeves onto garments with precision and accuracy. They must be able to follow patterns and instructions carefully, ensuring that the sleeves are attached correctly and securely.

- Attaching sleeves to armholes

- Adjusting sleeve length and width

2. Quality Control

Sleeve Sewers are responsible for checking the quality of their work. They must ensure that the sleeves are sewn evenly, with no puckering or loose threads. They must also inspect the seams for any defects or imperfections.

- Inspecting sleeves for defects

- Fixing any errors or imperfections

3. Production Output

Sleeve Sewers are expected to meet production targets while maintaining a high level of quality. They must work efficiently and effectively to ensure that the garments are completed on time.

- Meeting daily production goals

- Working independently and as part of a team

4. Safety and Maintenance

Sleeve Sewers must follow safety protocols and maintain their equipment. They must wear appropriate protective gear and keep their work area clean and organized.

- Following safety procedures

- Maintaining sewing machines

Interview Tips

To ace an interview for a Sleeve Sewer position, it is important to prepare thoroughly. Here are some tips to help you stand out:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific Sleeve Sewer position you are applying for. This will give you a better understanding of their needs and what they are looking for in a candidate.

- Visit the company website

- Read reviews from current or former employees

2. Practice Your Skills

Sleeve Sewing is a skilled trade, so it is important to be able to demonstrate your abilities during the interview. If possible, practice sewing sleeves on a garment or a sample piece of fabric. This will help you show the interviewer that you have the necessary skills for the job.

- Practice sewing straight lines

- Practice attaching sleeves to a garment

3. Highlight Your Attention to Detail

Sleeve Sewers need to have a keen eye for detail and be able to work accurately. In the interview, highlight your attention to detail by giving specific examples of how you have demonstrated this skill in your previous work experience.

- Mention any quality control experience you have

- Describe a time when you caught and fixed a mistake in your work

4. Show Your Enthusiasm

Interviewers are more likely to hire candidates who are enthusiastic about the job. Show the interviewer that you are genuinely interested in the position and that you are eager to learn and grow.

- Express your interest in the company and the position

- Ask questions about the job and the company culture

Next Step:

Now that you’re armed with the knowledge of Sleeve Sewer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Sleeve Sewer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini