Are you gearing up for a career in Sliding Joint Maker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Sliding Joint Maker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

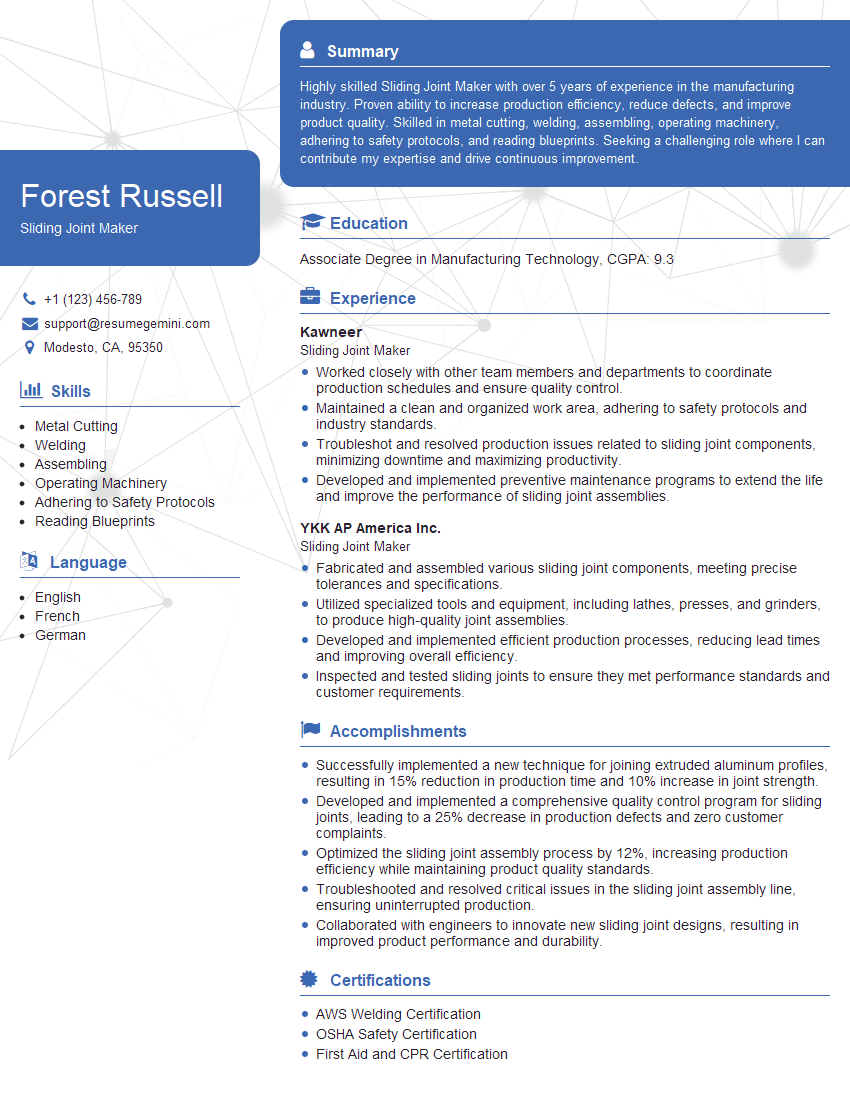

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sliding Joint Maker

1. Explain the process of making a sliding joint?

The process of making a sliding joint involves several steps. Firstly, the joint faces are prepared by cutting and machining them to the desired dimensions. Next, the joint faces are coated with a lubricant to reduce friction. Then, the sliding surfaces are assembled and secured together using mechanical fasteners, such as bolts or screws. Finally, the joint may be sealed to prevent leaks and ensure smooth operation.

2. What are the different types of sliding joints?

Types of sliding joints

- Linear sliding joints allow for movement in one direction, such as a drawer sliding in and out of a cabinet.

- Rotary sliding joints allow for rotation around an axis, such as a wheel rotating on a shaft.

- Curvilinear sliding joints allow for movement along a curved path, such as a ball bearing rotating within a race.

3. What are the advantages of using sliding joints?

- Smooth and efficient movement: Sliding joints allow for smooth and efficient movement between two surfaces.

- Reduced wear and tear: The use of lubricants in sliding joints helps to reduce wear and tear on the joint surfaces.

- Compact design: Sliding joints can be designed to be compact, making them suitable for applications where space is limited.

4. What are the challenges in designing and manufacturing sliding joints?

- Lubrication: Proper lubrication is critical for the smooth operation and longevity of sliding joints.

- Wear and tear: Sliding joints are susceptible to wear and tear over time, especially in demanding applications.

- Sealing: Sliding joints may need to be sealed to prevent leaks and ensure smooth operation.

5. What are the applications of sliding joints?

- Linear sliding joints: Drawer slides, cabinet slides, door tracks

- Rotary sliding joints: Wheels, bearings, gears, pumps

- Curvilinear sliding joints: Ball bearings, roller bearings, linear ball bearings

6. What materials are commonly used in sliding joints?

- Metals: Steel, aluminum, brass, bronze

- Plastics: Nylon, acetal, polyethylene

- Composites: Carbon fiber, glass fiber

7. What are the factors to consider when selecting a sliding joint?

- Type of movement: Linear, rotary, or curvilinear

- Load capacity: The amount of force or torque that the joint can handle

- Speed: The maximum speed at which the joint can operate

- Environment: The operating conditions, such as temperature, humidity, and exposure to chemicals

8. How do you ensure the quality of sliding joints?

- Inspection: Inspecting the joint components for defects and proper assembly.

- Testing: Conducting performance tests to ensure that the joint meets the required specifications.

- Documentation: Maintaining records of all quality control procedures.

9. What are the latest trends in sliding joint technology?

- Advanced materials: The development of new materials with improved strength, wear resistance, and corrosion resistance.

- Self-lubricating joints: The use of materials that provide continuous lubrication, reducing the need for external lubrication.

- Miniaturization: The design of compact sliding joints for applications with limited space.

10. What are the challenges you have faced in your previous sliding joint-related work?

- Designing a sliding joint for a high-load application: Ensuring that the joint could withstand the required forces without excessive wear and tear.

- Developing a self-lubricating sliding joint: Finding a material that would provide continuous lubrication under demanding operating conditions.

- Troubleshooting a noisy sliding joint: Identifying the source of the noise and implementing measures to reduce it.

11. How do you stay updated with the latest advancements in sliding joint technology?

- Attending industry conferences and exhibitions: Networking with experts and learning about the latest developments.

- Reading technical journals and articles: Staying informed about new materials, design techniques, and applications.

- Participating in online forums and discussions: Engaging with other professionals and sharing knowledge.

12. What are your strengths and weaknesses as a Sliding Joint Maker?

Strengths

- Expertise in designing and manufacturing sliding joints: Possessing a deep understanding of the principles and techniques involved in sliding joint design and manufacturing.

- Strong problem-solving and analytical skills: Ability to identify and resolve technical issues related to sliding joints.

- Experience in working with various materials: Familiar with the properties and applications of different materials used in sliding joint construction.

Weaknesses

- Limited experience with advanced materials: Less experience in working with cutting-edge materials such as composites and self-lubricating materials.

- Need to improve communication skills: Working on improving communication skills to effectively convey technical information to clients and colleagues.

13. Why are you interested in this Sliding Joint Maker position?

- Alignment with skills and experience: The position aligns well with my skills and experience in sliding joint design and manufacturing.

- Opportunity for growth: The role provides an opportunity to contribute to challenging projects and expand my knowledge in the field.

- Company reputation: I am impressed by the company’s reputation for innovation and quality in the sliding joint industry.

14. What are your salary expectations?

- Research industry benchmarks: Researched industry benchmarks and salary ranges for similar positions.

- Consider experience and qualifications: Considered my experience, qualifications, and the value I bring to the organization.

- Articulate expectations clearly: Prepared to articulate my salary expectations clearly and confidently during the negotiation process.

15. Do you have any questions for me about the Sliding Joint Maker position or the company?

- Inquire about the specific responsibilities: Seek clarification on the specific responsibilities and expectations associated with the role.

- Ask about the company’s growth plans: Show interest in the company’s future plans and how the role fits into them.

- Inquire about professional development opportunities: Explore opportunities for professional development and training within the organization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sliding Joint Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sliding Joint Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Sliding Joint Maker is responsible for operating and maintaining machinery used to manufacture sliding joints.

1. Equipment Operation and Maintenance

Operates and maintains machinery, including lathes, milling machines, and grinders.

- Sets up and operates machinery according to specifications.

- Inspects and maintains machinery to ensure proper operation.

2. Material Handling

Handles and moves materials, including metal bars, sheets, and castings.

- Loads and unloads materials from machinery.

- Inspects materials for defects.

3. Manufacturing Processes

Performs various manufacturing processes, including cutting, bending, and welding

- Cuts and bends metal bars and sheets to specified dimensions.

- Welds components to assemble sliding joints.

4. Quality Control

Inspects and tests finished products to ensure they meet quality standards

- Measures and inspects products for dimensional accuracy and surface finish.

- Performs tests to verify the strength and durability of products.

Interview Tips

To ace the interview for a Sliding Joint Maker position, it is important to:

1. Research the Company and the Position

Learn about the company’s history, culture, and products.

- Review the job description carefully.

- Identify the key skills and qualifications required for the position.

2. Practice Your Answers to Common Interview Questions

Prepare answers to questions about your experience, skills, and qualifications.

- “Tell me about a time when you had to solve a problem on the job.”

- “What are your strengths and weaknesses?”

3. Be Prepared to Discuss Your Experience in Detail

Be prepared to answer questions about your experience in operating and maintaining machinery.

- Highlight your skills in setting up and operating machinery.

- Describe your experience in inspecting and maintaining machinery.

4. Emphasize Your Commitment to Quality

Show that you are committed to producing high-quality products.

- Describe your experience in inspecting and testing products.

- Discuss your knowledge of quality control standards.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sliding Joint Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!