Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Slip Laster interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Slip Laster so you can tailor your answers to impress potential employers.

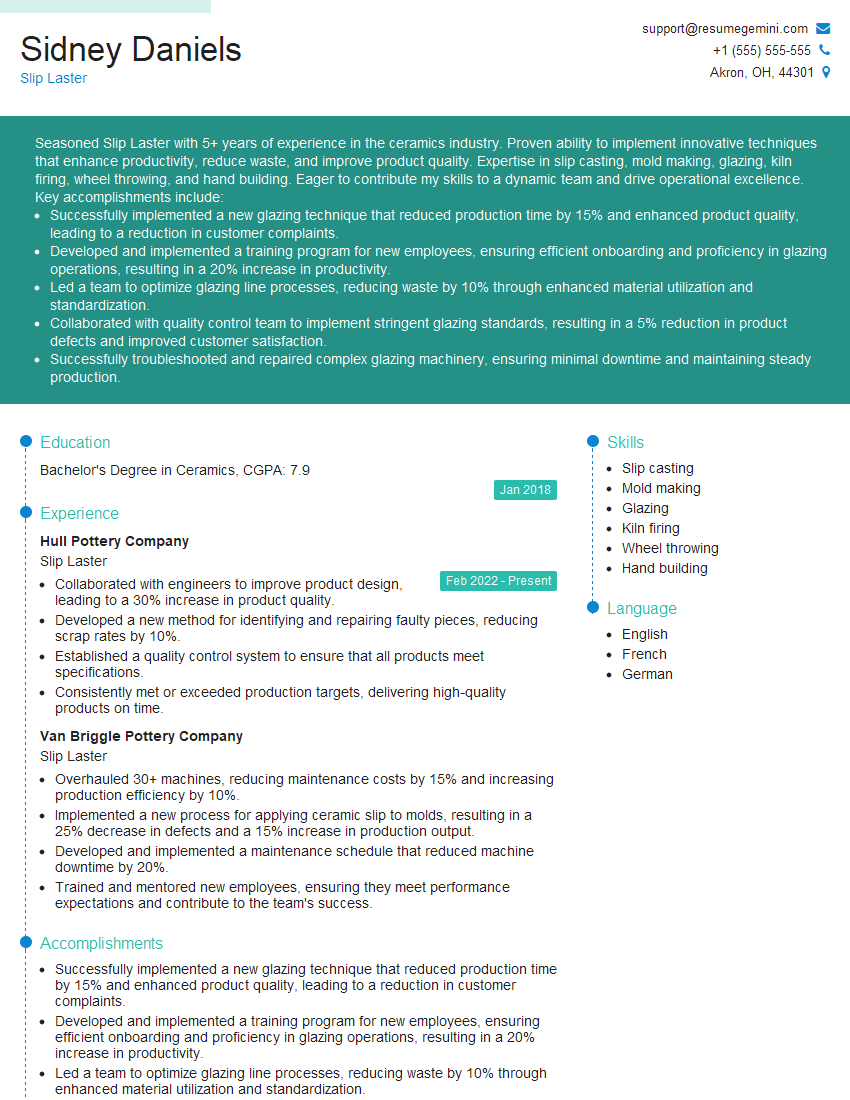

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Slip Laster

1. What are the key factors to consider when setting up a slip lasting machine?

When setting up a slip lasting machine, the following key factors should be considered:

- The type of material being lasted

- The size and shape of the last

- The desired degree of stretch or compression

- The type of adhesive or bonding agent being used

- The temperature and humidity of the environment

2. How do you troubleshoot common problems with slip lasting machines?

Mechanical problems

- Check for loose or worn parts

- Lubricate moving parts regularly

- Inspect belts and hoses for damage

Electrical problems

- Check for loose connections

- Inspect wiring for damage

- Test electrical components with a multimeter

Material problems

- Inspect material for defects

- Adjust tension settings

- Change the type of adhesive or bonding agent

3. What are the safety precautions that should be taken when operating a slip lasting machine?

The following safety precautions should be taken when operating a slip lasting machine:

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a dust mask

- Keep hands and feet clear of moving parts

- Do not operate the machine if it is not properly grounded

- Follow all manufacturer’s instructions

- Be aware of the location of the emergency stop button

4. What are the different types of slip lasting machines?

There are two main types of slip lasting machines:

- Manual slip lasting machines are operated by hand and require the operator to manually feed the material into the machine and control the tension. These machines are typically used for small-scale production.

- Automatic slip lasting machines are fully automated and can be programmed to perform a variety of operations, including feeding, tensioning, and lasting. These machines are typically used for high-volume production.

5. What are the advantages of using a slip lasting machine?

Using a slip lasting machine offers a number of advantages, including:

- Increased production speed: Slip lasting machines can significantly increase production speed compared to manual lasting methods.

- Improved accuracy and consistency: Slip lasting machines can produce more accurate and consistent results than manual lasting methods.

- Reduced labor costs: Slip lasting machines can reduce labor costs by eliminating the need for manual labor.

- Improved working conditions: Slip lasting machines can improve working conditions by reducing the risk of repetitive strain injuries and other health problems associated with manual lasting methods.

6. What are the different types of materials that can be lasted using a slip lasting machine?

A variety of materials can be lasted using a slip lasting machine, including:

- Leather

- Fabric

- Synthetics

- Rubber

- Foam

7. What are the different types of adhesives that can be used with a slip lasting machine?

A variety of adhesives can be used with a slip lasting machine, including:

- Water-based adhesives

- Solvent-based adhesives

- Hot-melt adhesives

- Pressure-sensitive adhesives

8. What are the different types of bonding agents that can be used with a slip lasting machine?

A variety of bonding agents can be used with a slip lasting machine, including:

- Stitching

- Staples

- Rivets

- Eyelets

9. What are the different types of lasts that can be used with a slip lasting machine?

A variety of lasts can be used with a slip lasting machine, including:

- Wood lasts

- Metal lasts

- Plastic lasts

- Combination lasts

10. What are the different types of slip lasting machines?

There are two main types of slip lasting machines:

- Horizontal slip lasting machines are designed to last the upper to the last in a horizontal position. These machines are typically used for lasting shoes with a high heel.

- Vertical slip lasting machines are designed to last the upper to the last in a vertical position. These machines are typically used for lasting shoes with a low heel.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Slip Laster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Slip Laster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Slip Laster is responsible for the creation and production of plaster molds used in the fabrication of ceramic pieces. The molds are used to form ceramic slips into a desired shape. Key responsibilities include:

1. Mold Preparation

Preparing and maintaining a variety of plaster molds for slip casting. Creating new molds from models or existing pieces.

2. Slip Casting

Preparing and mixing ceramic slips to the correct consistency. Pouring slip into prepared molds and controlling the thickness of the cast.

3. Mold Maintenance

Cleaning and repairing plaster molds to ensure their longevity and quality. Inspecting molds for damage and making necessary repairs.

4. Quality Control

Inspecting finished casts for defects and making adjustments to the casting process as needed. Ensuring that all casts meet the required standards and specifications.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some valuable tips to help you ace your Slip Laster interview:

1. Research the Company and Position

Research the company’s history, values, and the specific role you are applying for. This will demonstrate your interest and enthusiasm for the position.

2. Highlight Relevant Experience and Skills

Emphasize your experience and skills in mold making, slip casting, and quality control. Quantify your accomplishments whenever possible, using specific examples to illustrate your abilities.

3. Demonstrate Attention to Detail

Slip Lasting requires meticulous attention to detail. Highlight your ability to work accurately and consistently, ensuring the production of high-quality molds and casts.

4. Show Passion for Ceramics

If you are truly passionate about ceramics and the art of slip casting, let it shine through in your interview. Describe your interest in the field and how it motivates you.

5. Prepare Questions

Preparing thoughtful questions for the interviewer shows that you are engaged and interested in the position. Questions about the company’s processes, the team, and the growth potential are all appropriate.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Slip Laster role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.