Are you gearing up for a career in Slitter-Creaser-Slotter Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Slitter-Creaser-Slotter Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

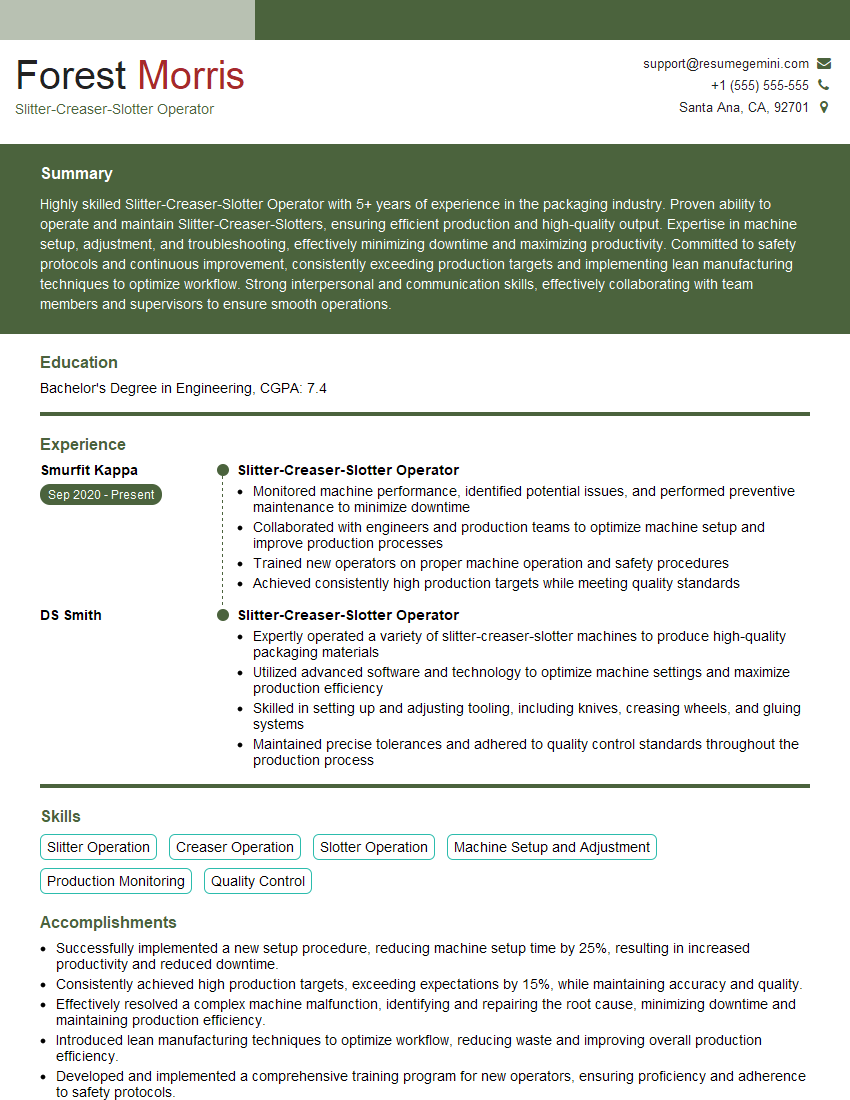

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Slitter-Creaser-Slotter Operator

1. Describe the main components of a slitter-creaser-slotter machine and explain their functions?

The main components of a slitter-creaser-slotter machine are:

- Unwind Stand: Holds and unwinds the paper or cardboard roll.

- Slitter: Cuts the material into narrow strips of desired widths.

- Creaser: Creates creases in the material for folding.

- Slotter: Cuts slots and holes in the material.

- Conveyor: Transports the finished product away from the machine.

2. What are the key factors to consider when setting up a slitter-creaser-slotter machine for a specific job?

Key factors to consider when setting up a slitter-creaser-slotter machine:

Material Properties:

- Type of paper or cardboard

- Thickness

- Grain direction

Job Requirements:

- Finished product dimensions

- Number of slits and creases

- Slot and hole shapes and sizes

Machine Capabilities:

- Blade sizes and settings

- Creasing wheel diameter and pressure

- Conveyor speed

3. How do you ensure accurate alignment and registration during the slitting, creasing, and slotting processes?

To ensure accuracy:

- Alignment Marks: Reference marks on the machine and material are aligned.

- Laser Sensors: Detect misalignments and adjust the machine settings automatically.

- Gauge Pins: Used to physically guide the material in the correct position.

- Regular Calibration: Machine sensors and settings are regularly calibrated for precision.

4. What are the most common problems that can occur during slitter-creaser-slotter operations, and how do you troubleshoot and solve them?

Common problems and solutions:

Material Jams:

- Misalignment or wrinkles in the material

- Tight blade settings or worn blades

Uneven Slits:

- Incorrect blade positioning or dull blades

- Material slipping during slitting

Scoring or Tearing During Creasing:

- Excessive pressure on creasing wheels

- Incorrect grain direction of the material

5. How do you maintain and inspect a slitter-creaser-slotter machine to ensure optimal performance?

Maintenance and inspection include:

- Scheduled Lubrication: Regular oiling and greasing of moving parts.

- Blade Sharpening or Replacement: Regular inspection and replacement of dull blades.

- Sensor Calibration: Ensuring alignment and registration sensors are working accurately.

- Conveyor Inspection: Checking for wear and tear, ensuring smooth operation.

- Safety Checks: Verifying machine guards and safety features are functional.

6. How do you optimize the efficiency of a slitter-creaser-slotter operation to minimize waste and maximize productivity?

Optimizing efficiency:

- Proper Machine Setup: Ensuring correct settings for material and job requirements.

- Roll Changes: Minimizing downtime during roll changes by preparing materials in advance.

- Job Scheduling: Grouping similar jobs together to reduce changeovers and waste.

- Waste Monitoring: Tracking waste generated and implementing measures to minimize scrap.

- Operator Training: Ensuring operators are skilled and efficient in machine operation.

7. What safety precautions and procedures must be followed when operating a slitter-creaser-slotter machine?

Safety precautions:

- PPE: Wearing proper safety gear, including gloves, safety glasses, and earplugs.

- Machine Guards: Ensuring all guards are in place and operational.

- Lockout/Tagout: Isolating the machine from power before performing maintenance or repairs.

- Clearance Areas: Maintaining clear workspaces around the machine to prevent tripping or accidents.

- Training: Receiving thorough training on safety protocols and emergency procedures.

8. How do you stay up-to-date with the latest advancements and best practices in slitter-creaser-slotter operations?

Staying updated:

- Industry Publications: Reading trade magazines and journals.

- Conferences and Webinars: Attending industry events to learn about new technologies and techniques.

- Manufacturer Training: Participating in training programs offered by machine manufacturers.

- Online Resources: Utilizing online forums and technical articles.

- Collaboration with Experts: Networking with other operators and industry professionals.

9. How do you handle machine breakdowns or malfunctions during operation?

Handling breakdowns:

- Immediate Safety: Ensuring the machine is safely isolated and powered down.

- Problem Identification: Diagnosing the problem using troubleshooting techniques.

- Repair or Replacement: Performing necessary repairs or replacing malfunctioning components.

- Communication: Informing supervisors or maintenance technicians about the issue and any actions taken.

- Prevention: Investigating the cause of the breakdown and implementing measures to prevent reoccurrence.

10. Describe a time when you faced a challenging situation or a quality issue while operating a slitter-creaser-slotter machine, and how you resolved it?

Example of a challenging situation:

I encountered an issue where the material was tearing during the creasing process due to excessive pressure on the creasing wheels. To resolve this, I carefully adjusted the pressure settings and monitored the material quality throughout the operation. Additionally, I checked the material’s grain direction and ensured it was in the correct orientation for creasing to prevent further tearing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Slitter-Creaser-Slotter Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Slitter-Creaser-Slotter Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Slitter-Creaser-Slotter Operator

A Slitter-Creaser-Slotter Operator plays a crucial role in the production process by operating a machine that performs multiple functions in the manufacturing of cardboard boxes. Here are the key responsibilities of this position:

1. Machine Operation and Maintenance

The primary responsibility of the operator is to operate the Slitter-Creaser-Slotter (SCS) machine effectively. This involves setting up and calibrating the machine according to specified job requirements, ensuring optimal performance and efficiency. The operator also performs routine maintenance tasks, such as cleaning, lubrication, and minor repairs, to keep the machine in working order.

- Setting up and adjusting the machine for different job requirements

- Monitoring machine performance and making adjustments as needed

- Performing preventive maintenance and minor repairs

2. Material Handling and Setup

The operator is responsible for handling and preparing raw materials, such as cardboard sheets, for processing on the SCS machine. This includes loading and unloading materials, ensuring proper alignment and positioning, and making adjustments to accommodate different material thicknesses and dimensions.

- Loading and unloading cardboard sheets onto the machine

- Adjusting machine settings based on material thickness and dimensions

- Inspecting materials for defects and ensuring quality standards

3. Quality Control and Inspection

The operator conducts quality control checks throughout the production process to ensure that the finished products meet specifications. This involves visually inspecting the processed cardboard sheets for defects, such as cuts, creases, and slots that do not meet the required standards. The operator also monitors the overall quality of the finished products and makes adjustments to the machine or process as necessary.

- Visually inspecting processed cardboard sheets for defects

- Identifying and correcting any errors or inconsistencies in the production process

- Maintaining quality records and reporting any issues to the supervisor

4. Safety and Compliance

Adhering to safety regulations and maintaining a clean and organized work environment are essential aspects of this role. The operator must follow established safety procedures, wear appropriate personal protective equipment (PPE), and report any potential hazards or accidents to the supervisor. They must also maintain a clean and well-organized work area to ensure efficient and safe operation.

- Following established safety procedures

- Wearing appropriate PPE

- Maintaining a clean and organized work area

- Reporting any potential hazards or accidents

Interview Preparation Tips for a Slitter-Creaser-Slotter Operator

To ace your interview for a Slitter-Creaser-Slotter Operator position, it’s important to prepare thoroughly and showcase your skills and experience. Here are some tips to help you succeed:

1. Research the Company and Industry

Take the time to research the company you’re applying to and the industry it operates in. Familiarize yourself with their products, services, and values to demonstrate your interest and understanding of their business. This will also help you ask informed questions during the interview.

- Visit the company website and social media pages

- Read industry news and articles

- Learn about the company’s competitors

2. Highlight Your Skills and Experience

Carefully review the job description and identify the key skills and qualifications required for the position. Match your skills and experience to these requirements and prepare examples that demonstrate your proficiency in each area. Quantify your accomplishments whenever possible to add credibility to your claims.

- Technical skills: operating Slitter-Creaser-Slotter machines, setting up and calibrating equipment, troubleshooting and repairing machines

- Quality control skills: inspecting materials and finished products, identifying defects, and maintaining quality standards

- Safety skills: following safety procedures, wearing PPE, and maintaining a clean and organized work environment

3. Practice Your Answers

Prepare answers to common interview questions, such as “Tell me about yourself,” “Why are you interested in this position?” and “What are your strengths and weaknesses?” Practice your answers out loud to ensure they are clear, concise, and engaging. This will help you build confidence and deliver your responses effectively.

- Research common interview questions and prepare answers

- Practice your answers out loud in front of a mirror or with a friend

- Time yourself to ensure your answers are within the appropriate length

4. Dress Professionally and Arrive on Time

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothing that is appropriate for a manufacturing environment. Arrive on time for your interview to show that you are punctual and respectful of the interviewer’s time. Punctuality also demonstrates your reliability and commitment to the job.

- Dress in clean, pressed clothing that is appropriate for a manufacturing environment

- Arrive on time for your interview

- Be prepared to shake hands and make eye contact with the interviewer

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Slitter-Creaser-Slotter Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.