Feeling lost in a sea of interview questions? Landed that dream interview for Slitter Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Slitter Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

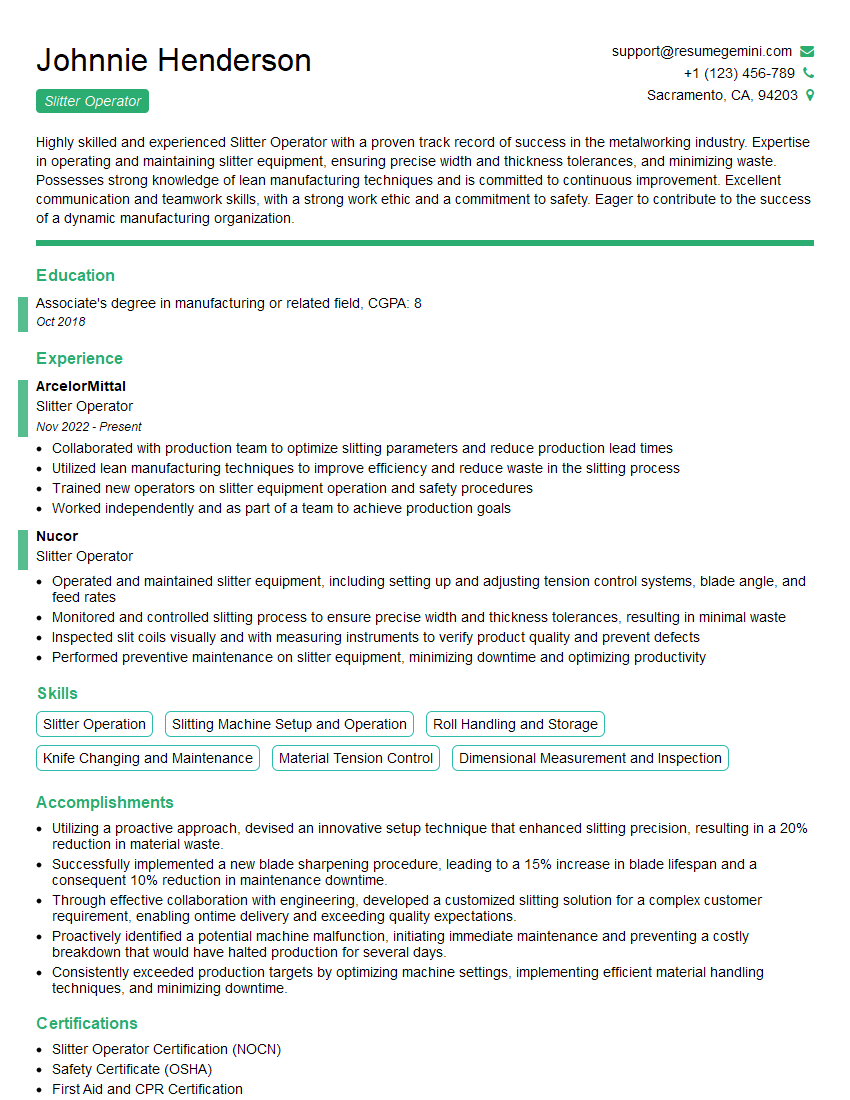

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Slitter Operator

1. Explain the process of setting up a slitter machine for a specific slitting job?

- Inspect the material to be slit, including its thickness, width, and length.

- Determine the desired slit widths and the number of slits to be made.

- Select the appropriate slitter knives and spacers.

- Adjust the slitter machine settings, including the speed, tension, and blade gap.

- Thread the material through the slitter machine and make any necessary adjustments.

- Run a test slit to ensure that the settings are correct.

2. What are the different types of slitter machines?

Mechanical Slitters

- Use a rotating blade to cut the material.

- Suitable for a wide range of materials, including paper, film, and foil.

Laser Slitters

- Use a laser beam to cut the material.

- Precise and suitable for cutting delicate or intricate materials.

Waterjet Slitters

- Use a high-pressure water jet to cut the material.

- Suitable for cutting thick or hard materials.

3. What are the key factors to consider when selecting a slitter machine?

- Type of material to be slit.

- Desired slit widths and number of slits.

- Production volume and speed requirements.

- Budget and space constraints.

- Safety features and maintenance requirements.

4. How do you maintain and troubleshoot a slitter machine?

- Regularly clean and lubricate the machine.

- Inspect the knives and spacers for wear or damage.

- Check the tension and speed settings.

- Troubleshoot any problems that occur, such as material jams or uneven slits.

5. What are the safety precautions to observe when operating a slitter machine?

- Wear appropriate safety gear, including gloves and safety glasses.

- Keep hands and fingers away from moving parts.

- Be aware of the location of the emergency stop button.

- Follow all operating instructions and safety procedures.

6. How do you ensure the quality of the slit material?

- Inspect the material before and after slitting.

- Check the slit widths and spacing.

- Look for any defects, such as tears or wrinkles.

- Make adjustments to the slitter machine as needed.

7. What are the common problems encountered when operating a slitter machine?

- Material jams.

- Uneven slits.

- Knife wear or damage.

- Tension problems.

- Electrical or mechanical failures.

8. How do you handle a material jam on a slitter machine?

- Stop the machine immediately.

- Identify the location of the jam.

- Carefully remove the jammed material.

- Inspect the material and the machine for any damage.

- Restart the machine and resume slitting.

9. What is the role of tension control in slitting?

- Tension control helps to prevent the material from stretching or shrinking during slitting.

- Proper tension settings ensure that the slit widths are accurate and consistent.

- Tension control also helps to reduce material waste and improve the quality of the slit material.

10. What are the latest trends in slitter technology?

- Automated slitting machines with advanced control systems.

- Laser slitting for precise and intricate cuts.

- Waterjet slitting for cutting thick or hard materials.

- Remote monitoring and diagnostics for improved maintenance and troubleshooting.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Slitter Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Slitter Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Slitter Operators are responsible for operating and maintaining slitter machines, which cut large rolls of material into smaller rolls or strips. They work in a variety of industries, including paper, plastic, and metal.

1. Operating Slitter Machines

Slitter Operators are responsible for the safe and efficient operation of slitter machines. This involves:

- Loading and unloading rolls of material

- Setting up the machine for the desired cut

- Monitoring the machine during operation

- Making adjustments as needed

2. Maintaining Slitter Machines

Slitter Operators are also responsible for maintaining their machines. This involves:

- Cleaning and lubricating the machine

- Inspecting the machine for wear and tear

- Making minor repairs

- Ordering replacement parts

3. Quality Control

Slitter Operators are responsible for ensuring that the finished product meets quality standards. This involves:

- Inspecting the finished product for defects

- Making adjustments to the machine as needed

- Reporting any quality problems to the supervisor

4. Safety

Slitter Operators work in a hazardous environment. They must be aware of the potential hazards and take precautions to avoid injury. This involves:

- Wearing appropriate personal protective equipment (PPE)

- Following safety procedures

- Reporting any unsafe conditions to the supervisor

Interview Tips

Succeeding in a Slitter Operator interview requires preparation and a strong understanding of the role. Here are some tips to help you ace your interview:

1. Research the Company and the Position

Take the time to learn about the company and the specific position you are applying for. This will help you understand the company’s culture, the role’s responsibilities, and the qualifications they are looking for.

- Visit the company’s website

- Read the job description carefully

- Talk to people who work for the company, if possible

2. Highlight Your Relevant Skills and Experience

In your resume and interview, be sure to highlight your relevant skills and experience. This includes your experience operating and maintaining slitter machines, your quality control experience, and your safety record.

- Quantify your accomplishments whenever possible

- Use action verbs to describe your skills and experience

- Tailor your resume and cover letter to the specific position you are applying for

3. Be Prepared to Answer Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to prepare answers to these questions in advance so that you can deliver them confidently and concisely.

- Practice your answers out loud

- Be prepared to give examples of your skills and experience

- Be enthusiastic and positive

4. Ask Questions

Asking questions at the end of the interview shows that you are interested in the position and that you have taken the time to prepare for the interview. It also gives you an opportunity to learn more about the company and the role.

- Ask about the company’s culture

- Ask about the role’s responsibilities

- Ask about the company’s growth plans

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Slitter Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.