Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sliver Lap Machine Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

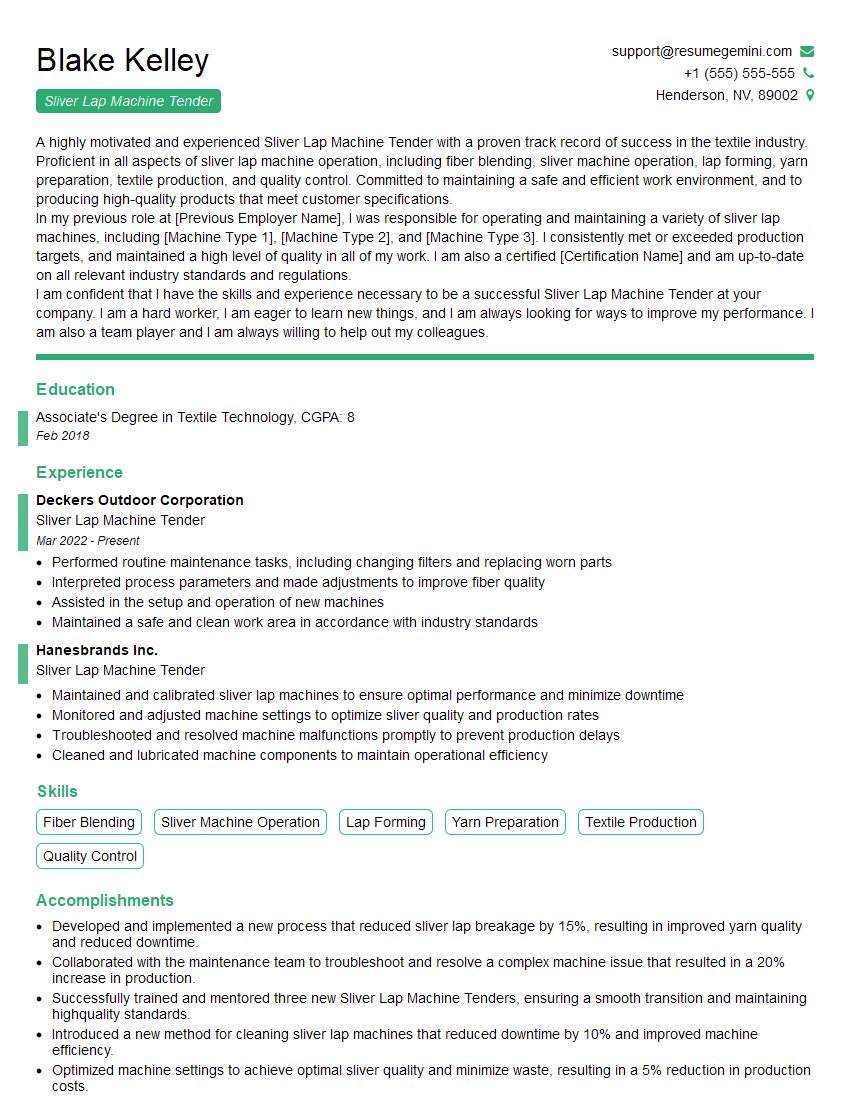

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sliver Lap Machine Tender

1. Explain the key steps involved in preparing a sliver lap machine for operation?

- Inspect the machine and ensure that it is in good working order.

- Clean the machine thoroughly, removing any dirt or debris.

- Install the correct lap roller and set the roller pressure.

- Adjust the lap speed and feed rate to the desired settings.

- Calibrate the machine to ensure accurate sliver production.

2. How do you monitor the sliver lap machine during operation to ensure the production of high-quality sliver?

- Regularly check the sliver for consistency, evenness, and thickness.

- Inspect the lap for any signs of wear or damage.

- Monitor the machine sensors to detect any fluctuations in temperature, pressure, or speed.

- Make adjustments to the machine settings as needed to maintain optimal production.

- Troubleshoot any issues that arise and take corrective actions to minimize downtime.

- Maintain a log of machine performance and any adjustments made to ensure consistent quality.

Monitoring Sliver Quality

Adjusting and Troubleshooting

3. Describe the process of troubleshooting common problems that may occur with a sliver lap machine?

Troubleshooting common problems with a sliver lap machine typically involves the following steps:

- Identify the problem and its symptoms.

- Check the machine’s sensors and gauges to identify any abnormal readings.

- Inspect the lap roller, feed rollers, and other components for wear or damage.

- Adjust the machine settings or replace worn components as necessary.

- Monitor the machine’s performance after making adjustments to ensure that the problem has been resolved.

4. Explain the importance of maintaining the sliver lap machine to ensure optimal performance?

- Regular maintenance prevents breakdowns and ensures consistent production.

- Proper lubrication reduces wear and tear on machine components.

- Cleaning and inspection help identify and address potential issues early on.

- Calibrating the machine ensures accurate sliver production and quality.

- Well-maintained machines operate more efficiently, reducing production costs.

5. How do you ensure that the sliver produced by the machine meets the desired specifications and quality standards?

- Monitor the sliver production regularly and make adjustments to the machine settings as needed.

- Conduct regular sliver quality tests to ensure that it meets the desired specifications.

- Analyze the test results and make adjustments to the machine or process as necessary.

- Maintain a record of the sliver quality tests for future reference and quality control purposes.

6. Explain the safety precautions that must be taken when working with a sliver lap machine?

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs.

- Keep the work area clean and free from debris.

- Never operate the machine with loose clothing or jewelry.

- Stay clear of moving parts while the machine is running.

- Be aware of the machine’s emergency stop buttons and know how to use them.

7. How do you handle situations where the sliver lap machine is not operating at optimal efficiency?

When the sliver lap machine is not operating at optimal efficiency, I typically take the following steps:

- Inspect the machine for any visible issues, such as worn or damaged components.

- Check the machine’s sensors and gauges to identify any abnormal readings.

- Review the machine’s maintenance history to determine if any scheduled maintenance tasks are overdue.

- Make adjustments to the machine settings or perform minor repairs as necessary.

- If the problem persists, I escalate the issue to my supervisor or a qualified technician for further troubleshooting.

8. How do you stay updated on the latest advancements and technologies in the field of sliver lap machine operations?

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Consult with experts in the field.

- Participate in online forums and discussion groups.

- Stay informed about new products and technologies from manufacturers.

9. Describe your experience in training and mentoring junior sliver lap machine operators?

I have been involved in training and mentoring junior sliver lap machine operators for the past [number] years. My approach to training typically involves the following steps:

- Provide comprehensive theoretical knowledge about the machine’s operation and maintenance.

- Conduct hands-on training sessions to develop practical skills.

- Supervise junior operators during actual machine operation.

- Provide feedback and guidance to help them improve their skills and knowledge.

- Encourage them to ask questions and actively participate in the training process.

10. Explain how your skills and experience make you a suitable candidate for this Sliver Lap Machine Tender position?

I am confident that my skills and experience make me a highly suitable candidate for this Sliver Lap Machine Tender position. My key strengths include:

- In-depth knowledge of sliver lap machine operation and maintenance.

- Proven ability to produce high-quality sliver that meets specifications.

- Strong troubleshooting and problem-solving skills.

- Excellent communication and interpersonal skills.

- Commitment to safety and adherence to industry best practices.

- Eagerness to learn and stay updated on the latest advancements in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sliver Lap Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sliver Lap Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Sliver Lap Machine Tender plays important role in the textile production process, responsible for operating and maintaining the sliver lap machine to produce high-quality sliver laps.

1. Machine Operation

The primary responsibility involves operating the sliver lap machine efficiently. This includes:

- Loading the machine with raw materials such as cotton or wool fibers.

- Starting, stopping, and monitoring the machine during the lapping process.

- Adjusting machine settings to ensure optimal sliver quality, weight, and thickness.

2. Machine Maintenance

Maintaining the machine is crucial to ensure smooth operation and prevent breakdowns. The tender is responsible for:

- Performing routine maintenance tasks such as cleaning, lubricating, and inspecting the machine.

- Identifying and troubleshooting any mechanical or electrical issues.

- Reporting any maintenance or repair needs to supervisors.

3. Quality Control

Ensuring the quality of sliver laps is essential. The tender is required to:

- Inspect the sliver laps for defects, such as unevenness, breaks, or foreign matter.

- Adjust machine settings or take corrective actions to maintain the desired sliver quality.

- Maintain records of production and quality control checks.

4. Safety

Operating a sliver lap machine involves potential hazards. The tender must adhere to:

- Safety regulations and guidelines.

- Use appropriate personal protective equipment (PPE).

- Report any unsafe conditions or practices

Interview Tips

Preparing thoroughly for an interview can increase your chances of success. Here are some tips:

1. Research the Company and Role

Familiarize yourself with the company’s background, industry, and specific role you are applying for. This will help you understand their needs and tailor your answers accordingly.

- Visit the company’s website.

- Read industry-related articles.

- Practice answering common interview questions.

2. Highlight Relevant Skills and Experience

Review the job description and identify the key skills and experience required. Highlight specific examples from your work history that demonstrate your abilities in these areas.

- Quantify your accomplishments using numbers whenever possible.

- Use the “STAR” method (Situation, Task, Action, Result) to structure your answers.

- Prepare examples of your attention to detail, problem-solving skills, and commitment to quality.

3. Prepare Questions

Asking thoughtful questions at the end of the interview shows your interest and engagement. Prepare questions related to the role, company, or industry to demonstrate your enthusiasm and curiosity.

- Ask about opportunities for professional development.

- Inquire about the company’s growth plans.

- Ask about the company’s commitment to sustainability.

4. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive for your interview on time. This demonstrates respect for the interviewer and the company.

- Choose attire that is clean, ironed, and appropriate for the industry.

- Plan your route and allow extra time for unexpected delays.

- Arrive at the interview location with a positive attitude.

5. Practice and Seek Feedback

Practice answering interview questions with a friend, family member, or mentor. Seek feedback on your delivery, content, and body language. This will help you improve your confidence and effectiveness.

- Record yourself answering questions to identify areas for improvement.

- Participate in mock interviews to gain experience in a simulated interview setting.

- Ask for constructive criticism to enhance your performance.

Next Step:

Now that you’re armed with the knowledge of Sliver Lap Machine Tender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Sliver Lap Machine Tender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini