Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Slotter Operator Helper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Slotter Operator Helper so you can tailor your answers to impress potential employers.

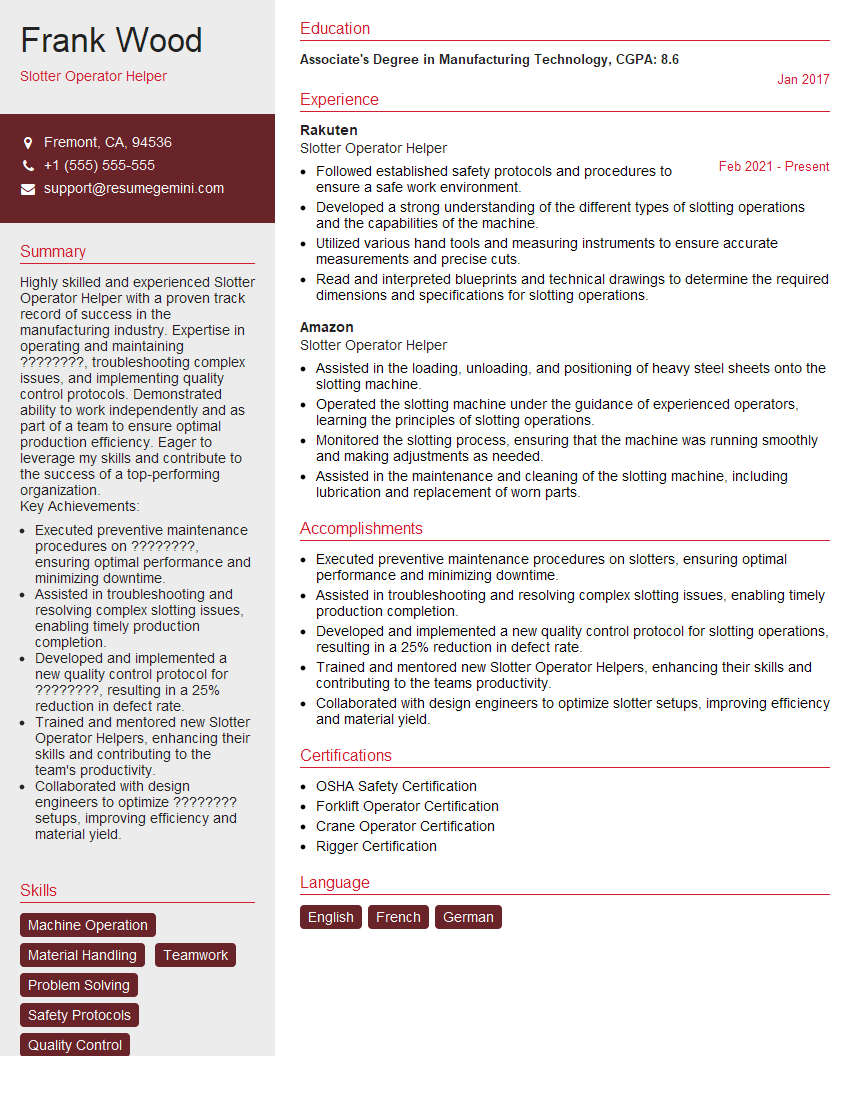

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Slotter Operator Helper

1. Describe what a slotter machine is, and explain its purpose in the manufacturing process.

A slotter machine is a versatile and powerful machine tool used to cut various shapes and features into metal workpieces. It consists of a rotating cutting tool mounted on a ram that moves vertically. The workpiece is held securely on a table and can be moved in different directions to achieve the desired cuts.

- Creates slots, keyways, and other shaped features in metal components.

- Used in a variety of industries, including automotive, aerospace, and general manufacturing.

- Enhances the functionality and performance of manufactured parts.

2. What are the different types of slotter machines?

- Horizontal Slotter: The ram moves horizontally, allowing for side-to-side cutting.

- Vertical Slotter: The ram moves vertically, enabling cuts in the up-and-down direction.

- Universal Slotter: Combines features of both horizontal and vertical slotters, providing greater versatility.

3. Explain the key safety precautions that should be taken when operating a slotter machine.

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Ensure the machine is properly grounded and regularly maintained.

- Secure the workpiece firmly to the table to prevent movement during cutting.

- Maintain a safe distance from the cutting tool and rotating parts.

- Never operate the machine while under the influence of drugs or alcohol.

4. Describe the process of setting up a slotter machine for a specific cutting operation.

Setting up a slotter machine involves several steps to ensure accurate and efficient cutting:

- Selecting the Cutting Tool: Choose the appropriate cutter based on the desired shape and size of the slot.

- Mounting the Cutter: Securely mount the cutter on the ram and adjust its height and angle.

- Positioning the Workpiece: Clamp the workpiece onto the table and align it correctly for the desired cut.

- Setting the Cutting Parameters: Determine the appropriate cutting speed, feed rate, and depth of cut based on the material and cutter specifications.

5. Explain how to use a slotter machine to cut a keyway.

- Select a keyway cutter and mount it on the ram.

- Position the workpiece and align it with the desired keyway location.

- Set the cutting parameters and plunge the cutter into the workpiece.

- Move the workpiece laterally to cut the keyway to the specified width.

- Gradually increase the depth of cut until the desired keyway depth is achieved.

6. Describe how to troubleshoot common problems that may occur while operating a slotter machine.

- Excessive Vibration: Check for loose bolts or improper workpiece clamping.

- Poor Surface Finish: Adjust the cutting speed or feed rate, or use a sharper cutter.

- Chattering: Reduce the cutting depth or feed rate, or ensure the cutter is properly balanced.

- Tool Breakage: Check for worn or damaged cutters, or excessive cutting forces.

- Safety Issues: Stop the machine immediately and address any safety concerns, such as loose guards or electrical hazards.

7. Explain the importance of preventive maintenance for slotter machines.

- Extends Machine Life: Regular maintenance reduces wear and tear, prolonging the lifespan of the machine.

- Improved Accuracy: Proper maintenance ensures optimal performance and accuracy of the slotter.

- Increased Productivity: Minimizes downtime and ensures the machine is always ready for use.

- Enhanced Safety: Regular inspections identify potential hazards and prevent accidents.

- Compliance with Regulations: Meets industry standards and regulatory requirements for machine maintenance.

8. Describe the different types of cutting tools used in slotter machines.

- Slotter Cutters: Used for cutting slots and keyways.

- End Mills: For milling operations, such as cutting pockets and profiles.

- Boring Tools: For enlarging existing holes or creating new ones.

- Facing Cutters: For squaring and leveling surfaces.

- T-Slot Cutters: For cutting T-shaped slots.

9. Explain how to calculate the cutting speed and feed rate for a given slotter operation.

- Cutting Speed: Determined based on the material being cut and the cutter material.

- Feed Rate: Dependent on the desired surface finish and material hardness.

- Formulas and charts are used to determine the appropriate values.

- Proper calculation ensures efficient cutting and optimal tool life.

10. Describe the importance of using coolants and lubricants in slotter operations.

- Cooling: Reduces heat generated during cutting, preventing tool wear and workpiece deformation.

- Lubrication: Minimizes friction between the cutter and workpiece, extending tool life.

- Chip Removal: Helps clear chips away from the cutting zone, improving surface finish.

- Corrosion Protection: Protects the workpiece and cutter from corrosion.

- Increased Safety: Reduces the risk of accidents due to flying chips.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Slotter Operator Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Slotter Operator Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Slotter Operator Helper plays a crucial role in the efficient operation of a slotter, which is a machine used to cut and shape metal. The key job responsibilities of a Slotter Operator Helper include:

1. Assisting the Slotter Operator

Assisting the slotter operator with machine setup, operation, and maintenance. This includes loading and unloading materials, setting up fixtures, and adjusting machine settings.

2. Material Handling

Assisting with material handling and movement, including loading and unloading raw and finished products from machines and storage areas.

3. Machine Maintenance

Performing routine maintenance and cleaning of the slotter machine, including lubricating and inspecting components to ensure optimal performance.

4. Quality Control

Assisting with quality control checks by measuring and verifying the accuracy of slotted parts against specifications.

Interview Tips

To ace the interview for a Slotter Operator Helper position, candidates should consider the following tips:

1. Research the Company and Position

Thoroughly research the company and the specific slotter operator helper position you are applying for. This will help you understand the company’s culture, industry, and the technical requirements of the role.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that directly relate to the job responsibilities of a slotter operator helper. Quantify your accomplishments and provide specific examples whenever possible.

3. Demonstrate Team Spirit

Slotter operator helpers often work as part of a team. Highlight your teamwork skills and ability to collaborate effectively.

4. Prepare for Technical Questions

Be prepared to answer questions about slotter machines, their operation, and maintenance procedures. You should also be able to discuss quality control processes and safety protocols related to the job.

Next Step:

Now that you’re armed with the knowledge of Slotter Operator Helper interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Slotter Operator Helper positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini